RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

How to ultra precision processing bearing ?

2022-11-16Ultra-precision grinding is a kind of feed movement to achieve a micro grinding of a finishing process.The surface before ultra-finish machining is generally precision turning and grinding.

Learn More

-

Bad feedback of electroplated diamond sanding belt for grinding alumina ceramics

2022-11-08If the fine grain size of dry grinding cannot be fed too much, it must be the high heat that causes the surface of the sand belt to turn yellow at high temperature, which will definitely affect the service life of the sand belt. The gap at the interface is allowed by normal technology, and the peeling is also caused by high temperature.

Learn More

-

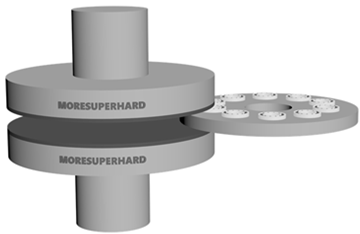

Diamond dresser for dressing aluminum oxide wheel

2022-11-07Diamond roller made of a large number of diamond particles embedded on the surface of a steel roller by electroplating or powder metallurgy. The diamond roller rotates at a certain speed and produces grinding and rolling effects on the surface of the high-speed rotating wheel, so that the grinding wheel can obtain a sharp working surface consistent with the profile of the roller. Dressing grinding wheel one-time forming, with high efficiency, high precision, durable characteristics, widely used in thread, gear, bearing, machine tools, automobiles, blades, cutting tools and so on.

Learn More

-

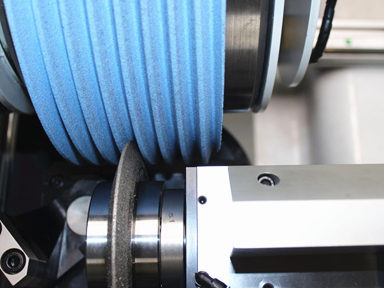

Bearing super finishing

2022-11-04Most bearings seen in daily life are ordinary bearings. However, high-end precision bearings applied in aero-engine, high-precision machine tool equipment, high-speed railway, instrumentation and other fields have unimaginable complexity in technology. The quality of a bearing is determined by its accuracy, performance in vibration, noise and noise, life and reliability, and high-speed performance. In the process of bearing production, the most critical links include forging, heat treatment, grinding, super finishing, rust prevention and so on.

Learn More

-

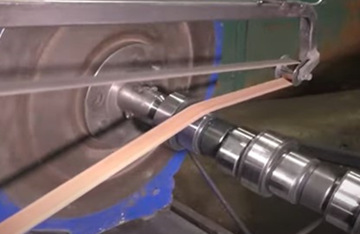

Why do crankshafts/camshafts need polishing?

2022-11-01Crankshafts are generally composed of spindle and connecting rod journals. Crank, balance block, front and back end, etc., the material is made of carbon structural steel or nodular cast iron. A spindle neck, a connecting rod diameter and a crank constitute a crank, the number of in-line engine crankshaft crank is equal to the number of cylinders; The number of bends in a V-engine is equal to half the number of cylinders.

Learn More

-

Hydraulic industry hole honing solution

2022-10-21In order to solve the problems of low precision and short life of hole processing in hydraulic industry,Moresuperhard diamond honing reamer, with honing machine, machining center and drilling press for grinding, the superhard energy of diamond abrasive can ensure the high precision and high efficiency of hydraulic parts aperture.

Learn More

-

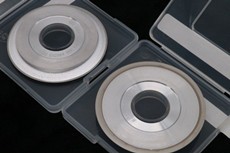

Semiconductor die sawing

2022-10-10According to different wafer materials, choosing the right cutting tool can help to reduce or eliminate the damage to the edge of the product and improve the pass rate of the product. More Superhard Products Co., Ltd. is mature and stable in the manufacturing process of the dicing blades, and enjoys good stability and long life in the field of semiconductor die sawing, which is favored by the customer groups

Learn More

-

Cylindrical grinding method and the choice of grinding allowance

2022-09-11Cylindrical grinding method Many shapes, sizes and types of bearings exist including: ball bearings, roller bearings, needle bearings, and tapered roller bearings

Learn More

-

How to ultra precision processing bearing ?

2022-09-09Ultra-precision grinding is a kind of feed movement to achieve a micro grinding of a finishing process.The surface before ultra-finish machining is generally precision turning and grinding.

Learn More

-

How to ultra precision processing bearing ?

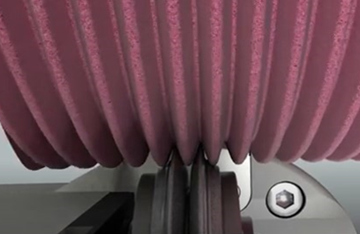

2022-09-09Bearing super finishing, also known as super finishing, is a micro-grinding process. For high-precision bearings, usually the ring rolling surface and the working surface of the rolling body need to be ultra-finished.

Ultra-finish machining has different processing equipment, processing principles are not the same, in order to achieve the geometric accuracy requirements, surface quality requirements, it is necessary to consider the equipment, tooling, whetstone, grinding fluid, and even the grinding process bearing parts of the state.Learn More