RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

What material can Virtifed CBN grinding wheel process?

2022-09-08Vitrified bond CBN grinding wheels are increasingly used in the fields of grinding micro-bearings in the inner circle (for magnetic tape, video recorder and office automation equipment), grinding cams or grooves, or honing automotive parts. This is because vitrified CBN grinding wheel or honing strip is different from resin, metal or electroplating bond CBN grinding wheel, it is particularly suitable for the above field of large-scale production needs. This paper mainly discusses the differences of CBN grinding wheel with different bond agents and their grinding effects, enumerate some practical examples of cubic boron nitride grinding tools with vitrified bonding agents and the selection methods of grinding parameters and grinding tools specifications.

Learn More

-

How to achieve mirror surface roughness?

2022-08-25The surface roughness of the workpiece after grinding is Ra<0.01μm, and the light is like a mirror, which can image clearly, so it is called mirror grinding. The flatness of the grinding plane is not more than 3μm/1000mm. Surface machining of high precision and high added value parts requires mirror grinding.

Learn More

-

ATC

2022-08-19ATC as the largest, most technologically advanced and most attended automotive intelligent manufacturing event in China, ATC intelligent manufacturing technology is mainly focus on “intelligent electric +” under the transformation of auto intelligent manufacturing, discusses automobile manufacture four process, SanDian systems, powertrain and parts of the latest workshop planning, application of new technology, new technology, new equipment and other manufacturing hot topic, promote technical exchange of enterprises and people in different regions of the world.

Learn More

-

Learning about DANOBAT course automobile powertrain efficient grinding solution

2022-08-12Learn More

-

The difference between diamond sanding belt and diamond grinding belt

2022-08-04Both diamond abrasive belts and diamond grinding wheel are the cumulative effect of micro-cutting of the “micro-edge cutting tool” with high speed — abrasive particles, so their grinding mechanism is roughly the same. However, due to the different characteristics of sand belt composition and use mode, the grinding of diamond polishing belts is different from diamond wheel grinding in terms of both grinding mechanism and comprehensive grinding performance. The main performance is as follows

Learn More

-

How to select grinding fluid in different grinding methods?

2022-08-01During metal grinding process, it is very important to choose the right grinding fluid in order to obtain the ideal machining accuracy and surface quality. Different metal grinding processes have different processing phenomena and different requirements on grinding fluid, so the grinding fluid used is more different.

Learn More

-

The difference between hubless dicing blade and hub type electrofromed dicing blade ?

2022-07-18The diamond dicing blade is a kind of diamond cutting disc that needs different specifications for different models. Thin diamond cutting disc are usually used for slotting or cutting. In order to distinguish different cutting disc, thin diamond cutting disc are divided into ” hubless dicing blade and hub type electrofromed dicing blade”.

Learn More

-

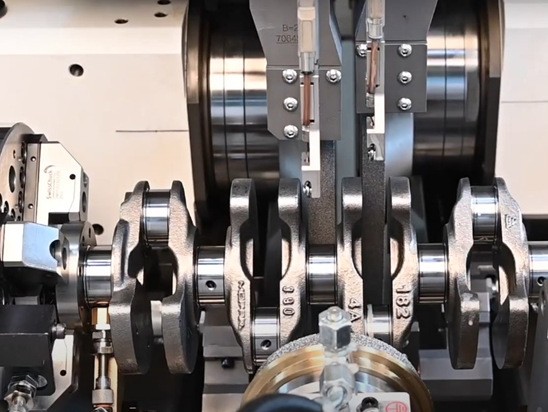

How to achieve high precision grinding crankshaft

2022-07-13Crankshaft is also a very unique part, no other part processing requires so many different processes, it is thin and long, the materials used in poor machining performance. Among them, the accuracy of thrust surface (including thrust journal and width) is more and more high, and R. A significant characteristic of thrust surface is that its contact area is much larger than that of other shaft collar sides, and the accuracy requirements are also much higher. Vitrified CBN grinding wheel is the ideal tool for crankshaft grinding, control is very sensitive, preventing burns during grinding.

Learn More

-

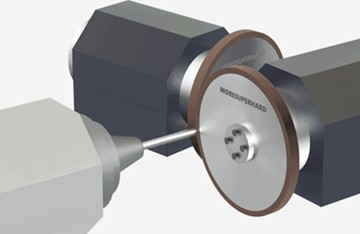

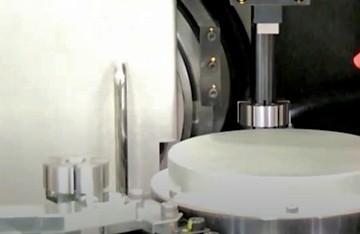

How to achieve high precision pinch and peel grinding?

2022-07-06For high precision CNC cylindrical peel grinding machine, widely used for profile cylindrical peel grionding former working procedure of milling cutter, drill bit, tapping, non – standard carbide rotary tools .

Learn More

-

How to high precision rotor grooving?

2022-06-30The rotor is a key part of the vane pump/motor. The material is 38CrMoAlA and the surface of the rotor groove is nitrified. Because the size accuracy, shape and position tolerance and surface roughness of this part are high requirements, the groove is narrow and deep, so the grinding wheel should be considered to have chemical inertia and high hardness, not need dressing in the process of use, so the selection of vitrified or electroplated CBN grinding wheel is more suitable.

Learn More