RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

Do you know how centerelss grinding work?

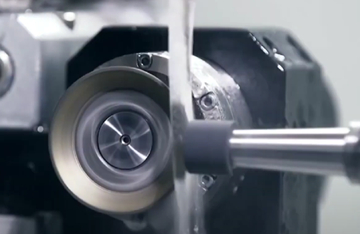

2022-06-22Centerless grinding is on centerless grinding machine, which interacts with regulating wheel and supporting plate to grind workpiece cylinder. During grinding process, no spindle or fixture is used to locate and secure the workpiece, workpiece is between the grinding wheel and the regulating wheel, supported by the support plate below, and the regulating wheel drives the cylindrical workpiece to rotate on the pad iron. Centerless grinding can also be used for inner circle grinding. During machining, the outer circle of the workpiece is supported on the roller or the supporting block, and the workpiece is driven to rotate by the eccentric electromagnetic suction ring. The grinding wheel extends into the hole for grinding. Centerless inner circular grinding is usually used to grind inner groove of bearing ring on special grinding machine for bearing ring.

Learn More

-

Influence of dressing interval of CBN internal grinding wheel on grinding effect

2022-06-13CBN grinding wheel has high hardness and wear resistance, and the material removal rate of CBN grinding wheel is higher than that of ordinary grinding wheel.

Learn More

-

Learn about dressing of grinding wheel

2022-06-02In the grinding process, under the action of friction and extrusion, the edges and corners of the grinding wheel gradually become round and blunt, or in the grinding of tough materials, the grinding debris is often embedded in the pore of the grinding wheel surface, so that the surface of the grinding wheel is blocked, and finally the grinding wheel loses its cutting ability.

Learn More

-

What problems should be paid attention to in the process of roller grinding machine?

2022-06-01The grinding efficiency of super hard abrasive is higher than conventional abrasive,Moresuperhard diamond grinding wheel used for WC hard alloy roll ring process, CBN grinding wheel used for HSS Roller process. Moresuperhard have resin/metal/ electroplated diamond grindng wheel for roll ring grinding and roll cylindrical grinding.

Learn More

-

How to solve grinding vibration veins during hole grinding ?

2022-05-31CBN internal grinding wheel for grinding hole requires the machine to have enough rigidity and the grinding wheel to keep enough stable state, otherwise it is easy to produce grinding vibration veins, especially for processing thin-walled disc parts with inner holes.

Learn More

-

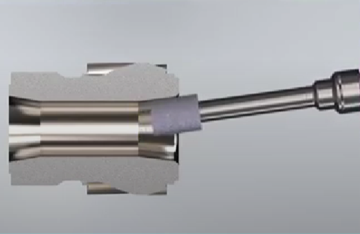

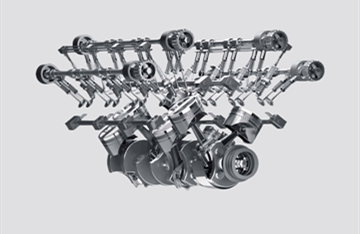

How do valves in an engine work?

2022-05-19CBN grinding wheel has the characteristics of high sharpness and wear resistance, high hardness and large grinding ratio. Engine valve grinding processes include external grinding, valve disc seat grinding, chamfering grinding, arc grinding and other parts. Groove profiles using Moresuperhard Electroplated CBN grinding wheel, valve keeper groove profiles can be formed precisely with accuracy down to the micrometre.

Learn More

-

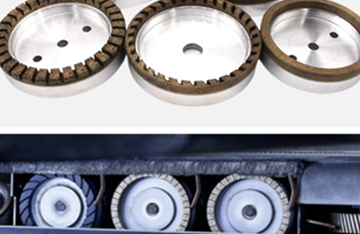

How to improve the edge grinding quality of glass?

2022-05-13Glass cutting needs to use glass edging machine for edging processing glass edging machine is mainly through grinding head motor and grinding wheel to achieve glass grinding and polishing, ordinary unilateral/bilateral edging machine can achieve rough grinding and fine grinding and polishing once completed customers can choose different grinding wheels according to their own processing requirements.

Learn More

-

How to do an Efficient Double Disc End Face Grinding ?

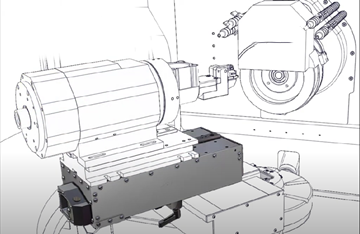

2022-05-06Double disc end face grinding technology is a must to find an efficient grinding solution to meet various requirements of the workpieces. A wide range of grinding tasks and a large variety of work, which require more precision and flexibility of grinding itself. The face grinding especially double face grinding is necessary.

Learn More

-

How to select dressing wheel?

2022-05-05In the grinding process, dressing plays a vital role in continuous and consistent processing, and dressing is divided into shaping and sharpening. Shape modification: The shape of the grinding wheel changes during the grinding process, and it is necessary to restore the grinding wheel to the desired state (including shape and accuracy, etc.) by dressing. Sharpening: abrasive will become blunt in the process of work, need to be blunt repair, new abrasive, sharp and leakage.

Learn More

-

How to select diamond grinding wheel for high precision grinding PCBN cutter?

2022-05-05In order to make PCBN cutting tools give full play to its performance, cutting tool edge treatment is a problem that must be considered. Whether PCBN cutting tool treatment is reasonable directly affects the tool life.

Learn More