RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

How to high precision process bearing?

2022-04-30Bearing is an indispensable core component in mechanical and electronic equipment. Its main management function is to support the Chinese mechanical rotating body, reduce the influence coefficient of trade friction and ensure the rotation accuracy. Regardless of aircraft, cars, high-speed rail or high precision machine tools, all rotating parts generally need bearings.

Learn More

-

How to cutting/grinding/polishing titanium alloy materials

2022-04-14In terms of pcd tool angle, a smaller rake angle is generally selected for cutting titanium alloys to increase the contact length between the chip and the rake face; at the same time, a larger clearance angle is selected to reduce the friction between the flank face and the machined surface.

Learn More

-

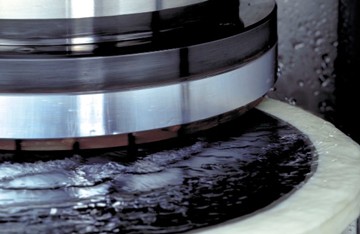

How to high precision back grinding wafer ?

2022-03-29Wafer back grinding is a step in semiconductor device manufacturing in which wafer thickness is reduced to allow stacking and high-density packaging of integrated circuits.

Learn More

-

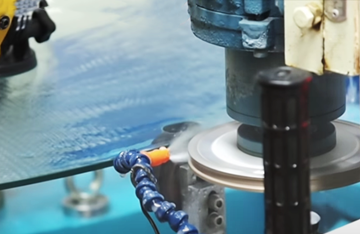

compared with ordinary glass and traditional coated glass for building

2022-03-25Glass bevel machine is generally used for glass chamfering grinding, glass bevel machine is suitable for grinding the bevel and bottom of flat glass of different sizes and thicknesses. The glass bevel machine integrates rough edges, fine grinding, polishing, bottom edges and other processes in one go. Useing diamond grinding wheel for rough grinding and sharpening. Fine grinding with diamond grinding wheel, high grinding accuracy. Polishing with wool polishing wheel, the surface gloss after processing is high. The polished glass surface can achieve a mirror effect.

Learn More

-

Application of honing process in automobile parts manufacturing

2022-03-03Honing is a method of finishing workpiece surface at low cutting speed. It is a special form of grinding and an efficient machining method in finishing machining.

Learn More

-

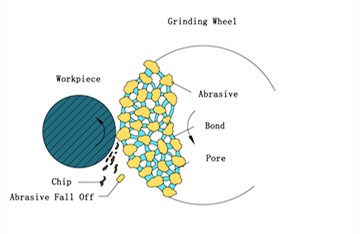

Learn more about grinding technology

2022-02-25Grinding is a processing method that removes the excess layer of workpiece surface by cutting action of abrasive tools to makes the surface quality of workpiece reach the predetermined requirements. Common grinding processing forms are: cylinder grinding, internal grinding, centerless grinding, thread grinding, surface grinding, forming surface grinding and so on.

Learn More

-

How to grind thermal spray coating?

2022-02-18When grinding the coating, we should pay attention to the fact that there is a great difference between the forging and casting parts of the same material. Excessive grinding pressure will cause the transfer or movement of particles on the surface of the coating, and even cause cracks in the coating. Due to poor thermal conductivity of the coating, there should be sufficient cooling medium during grinding.

Learn More

-

Moresuperhard 2021 Review

2022-02-18Learn More

-

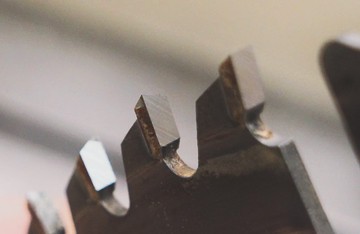

How to choose diamond grinding wheel for sharpening circular saw blade?

2022-01-28Carbide saw blade is usually used for wood products. How to sharpen the carbide saw blade correctly is related to the sharpness and service life of carbide saw blade. Therefore, it is important to choose suitable diamond grinding wheels for sharpening carbide saw blades except for technology.

Learn More

-

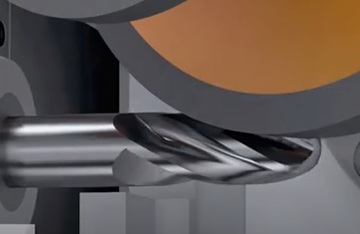

How to high precision flute grinding CNC tools?

2022-01-08Flutting grinding is one of the most demanding and time-consuming operations, as the cutting depth is typically 7-8 mm. The large contact area makes it difficult for the coolant to reach the grinding zone, so excessive heat will be generated, which may cause damage to the workpiece surface or reduce the particle strength of the thermosensitive diamond abrasive.

Learn More