RELATED BLOG

-

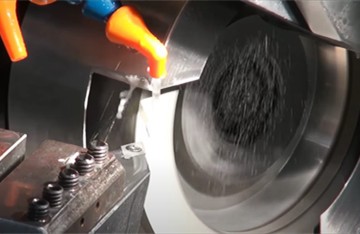

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

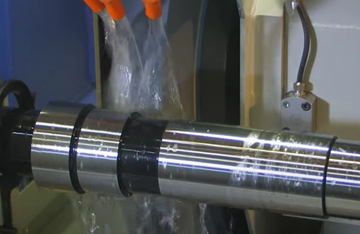

How to high precision grinding Crankshaft

2022-01-07Crankshaft is the core component to ensure the normal operation of the engine. Therefore, every part of the crankshaft, such as flange end, shaft head end, spindle neck and connecting rod neck, must be precisely grinded.

Learn More

-

Influence of binder on grinding wheel performance

2021-12-24Bond refers to the material bonded various bonding bond and abrasives. Bonded abrasives usually use vitrified, resin, metal and other bond. Binders can be divided into inorganic binders and organic binders.

Learn More

-

What’s the difference of drilling, reaming, boring and honing

2021-12-21Drilling is the first process of machining holes in solid materials. The diameter of drilling hole is generally less than 80mm. The common drilling tool has Twist drill, Center drill, Deep hole dWhat’s the difference between drilling, boring, reaming and honing? It’s hard for most people to tell the difference. Now I will be explain creating and modifying hole on a work-piece differences to yourill, etc.

Learn More

-

How to high precision process bearing?

2021-12-17The cylinderical grinding of the bearing ring needs to be processed by centerless grinding machine. Generally speaking, the segmented centerless grinding can achieve very high accuracy. It is mainly divided into coarse grinding, semi-fine grinding, fine grinding. Each stage removes enough margin to ensure that the next grinding stage does not cause problems such as burns or ripple marks. After fine grinding, the product can reach the dimensional precision of finished product. Centerless grinding are also used for machining small size rolling bodies such as rollers and needles.

Learn More

-

What problems often occur with centerless grinding method?

2021-12-06During the process of centerless grinding, the grinding wheel rotates at a high speed for grinding, while the regulating wheel rotates in the same direction at a slower speed to drive the workpiece to rotate for circular feed.

Learn More

-

Basic Knowledge of Grinding

2021-11-25Grinding is a mechanical processing method that removes material. In a narrow sense, it refers to the processing method of removing excess material on the workpiece with an abrasive tool. Grinding wheels, superabrasive tools, grinding heads, mounted points, sand tiles, oilstones, abrasive belts, etc.

Learn More

-

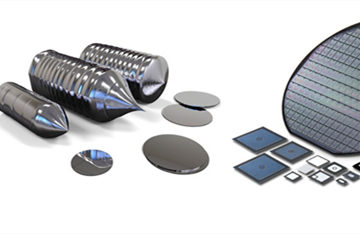

Application of diamond grinding wheel in semiconductor industry

2021-11-19The diamond grinding wheel of #800(particle size 20 μm) can quickly remove the surface material of gallium oxide wafer without cleavage breaking, but the surface damage is serious and there are a lot of obvious microcracks. The surface quality of gallium oxide wafer grinding with diamond wheel 1000(grain size 16 μm) was significantly improved, and only a few microcracks were observed on the wafer surface. The ultra-smooth surface processing technology of gallium oxide wafer was determined by using #800 diamond grinding wheel, #1000 diamond grinding wheel and silica sol polishing solution successively.

Learn More

-

The main points of the sharpening process of PCD and PCBN tools

2021-11-17One of the purposes of cutting tool sharpening is to obtain cost-effective cutting edge quality, and the key to quality is the choice of the size of the sharpening wheel. The finer the particle size of the grinding wheel, the smaller the chipping of the cutting edge, and the lower the grinding efficiency.

Learn More

-

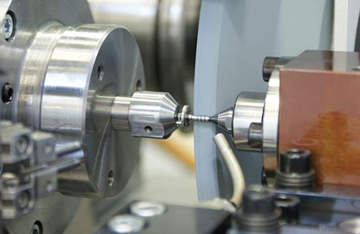

Three methods of cylindrical grinding

2021-11-16Cylindrical grinding generally has longitudinal grinding, horizontal grinding and deep grinding three ways.

Learn More

-

What problems will be encountered in the grinding process of double-sided grinding machine grinding wheel?

2021-11-11The hardness of CBN grinding wheel is too high: the grinding wheel with proper hardness should be replaced.

Learn More