How to select diamond grinding wheel for high precision grinding PCBN cutter?

In order to make PCBN cutting tools give full play to its performance, cutting tool edge treatment is a problem that must be considered. Whether PCBN cutting tool treatment is reasonable directly affects the tool life.

What is PCBN cutting edge treatment?

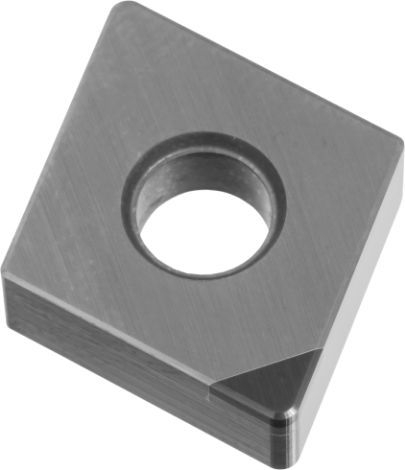

The cutting tool edge of a tool refers to the interface between the front and back surfaces of the blade where the workpiece material separates to form chips and the machined surface.

Cutting edge processing, is after the blade grinding, through the edge of chamfering, passivation, leveling, polishing and other processing, so as to improve the quality of the tool and improve the service life of the tool.

Why we need treatment cutting tool edge?

After grinding with diamond grinding wheel, PCBN cutting tool often has a certain degree of micro notch, such as tiny chipping edge, saw edge, etc. In the process of cutting, the micro notch on the cutting edge is easy to expand, which will accelerate the tool wear and damage. In order to eliminate the micro-defects of the cutting edge, the cutting edge should be treated.

PCBN blade after cutting tool edge treatment, the cutting tool can be strengthened, but also can improve the wear resistance of the tool, thus prolonging the tool life.

Due to the high hardness and brittleness of PCBN cutting tool, in order to meet the requirements of cutting processing, usually on the tool grinding negative chamfering, PCBN tool in hard car processing, the general use of rake Angle and negative chamfering processing, on the one hand can make the blade be reinforced, but also improve the wear resistance of the tool, in the processing of hardened steel or gray cast iron, provide different machining edge strength required by each. After grinding with diamond grinding wheel, there often exist micro notch of different degree (micro chipping edge and cutting tool edge) on the cutting edge. In the process of cutting, the micro-notch on the cutting edge is easy to expand, which speeds up the tool wear and damage. After the negative front Angle design and negative chamfering fine grinding, improve the strength of the tool, at the same time using blunt circle processing, eliminate the edge of the processing of micro defects, two kinds of processing methods, improve the impact strength of the tool, increase the wear resistance of the tool, thus prolonging the tool life.

The higher the quality of the cutting edge, the finer the cuting tool marks left at the boundary of the tool geometry reflection area of the workpiece surface, and the higher the surface finish of the workpiece. Because the edge is broken or extended easily cause tool wear or damage, reduce the tool life. Edge breakage is the key index of diamond cutting edge quality.

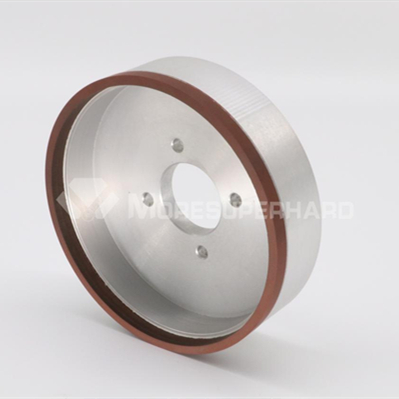

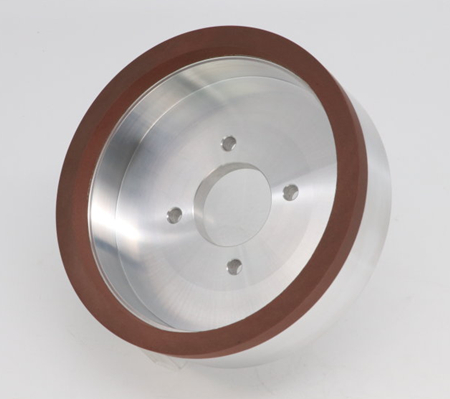

Moresuperhard can provide vitrified/resin diamond grinding wheel for PCBN chamfering grinding . This customer chose vitrified diamond wheels for grinding PCBN chamfering. In addition to customization, we also provide standard 6A2 resin diamond grinding wheel for PCBN chamfering grinding, coarse grinding grain W35 also received very good feedback from customers in practical applications.

—EDITOR: Doris Hu,Miya Ma

—POST: Doris Hu