Semiconductor Packaging –The Cutting of DFN Finished Products

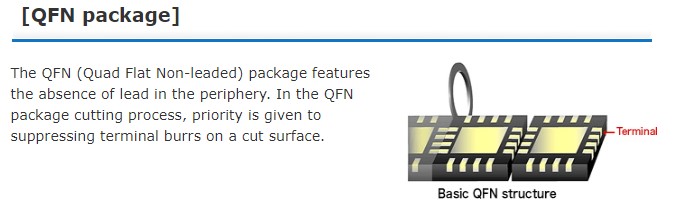

With the continuous progress of electronic information, the semiconductor industry is also changing with each passing day. In order to meet the market demand, the manufacturing process of all kinds of electronic control components is also developing towards the direction of small volume, excellent performance and low energy consumption. Such as IC packaging DFN, QFN, BGA and other process types.

At present, IC packaging finished product cutting to the overall soft dicing blade, how to ensure the qualified rate of packaging finished product cutting? In addition to the product structure design, equipment precision, manufacturing process, production environment, can not do without the precise selection of cutting blade and blade overall stability. The following is a brief introduction of our independent design, research and development, production of the overall soft blades and actual processing cases.

Principle of solid dicing blade machining DFN

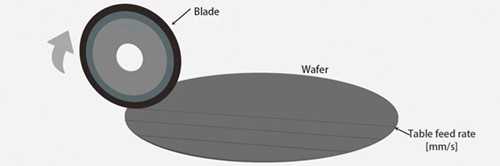

The cutting blade is mounted on the soft blade flange of the cutting equipment’s spindle. Under high-speed rotation of the spindle at 20,000 to 30,000 RPM, diamond particles on the blade are impacted to break parts of the workpiece that need to be cut, and Chip Pocket is used to timely remove cutting fragments to ensure product quality.

Introduction of solid dicing blade

Resin dicing blade is suited for cutting hard and brittle materials,such as QFN, sapphire, quartz and glass, etc.

Application

Main processing: DFN, QFN, PCB, BGA, LGA, glass, and other materials.

Through concentration, binder and diamond particle adjustment, it can effectively improve the processing quality, blade utilization rate and solve common quality problems, such as metal burr, product layering, pin tin-melting, cutting process cutter, serpentine cutting, breakage, etc.

Cutting Cases

| Machine Type | DISCO 3350 | Dicing Blade | 1A8 SD240 58*0.3*40 |

| Product Type | DFN 2*2 | Speed of mainshaft | 25000rpm |

| Product Size | 256*70mm | Die size | 2.0mm*2.0mm |

| Coolant temperature | 12±2° | Flow rate | 1.5L/m |

| Product Material | Copper+Epoxy Resin | Feed Speed | 40mm/s |

| Cutting Mode | Single shaft cut through | Machining Efficiency | 15 minutes |

| Processing Method | UV film cut | Cutting Depth | 0.1mm |

| Product Thickness | 0.75mm | Film Thickness | 0.15mm |

| Cutting slot width | 0.3mm | Cutting Life | About 2000m |

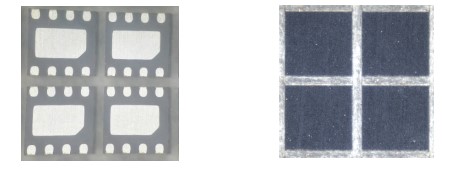

Cutting Effect

No burr, fracture and metal lamination were examined under 40 power microscope.

By selecting the suitable processing consumables, cooperating with scientific processing parameters, makes the cutting processing easier, we can offer high performance, high precision, difficult to market, good quality, long service life, reasonable price cutting blade, as well as the overall solution, to help customers enhance the level of technology and win more market.