Single stroke honing process VS multi-stroke honing process

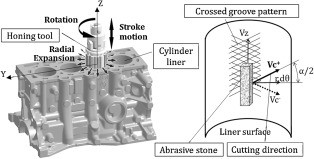

Multi-stroke honing process and single-stroke honing process. Multi-stroke honing process means that the honing head can make several strokes during the processing of the workpiece. There are mainly horizontal and vertical honing machines to choose from.

Single stroke honing process means that during the process, the honing tool is processed to the end at one time without any back and forth strokes. In general, several honing spindles (four and six axes are common) are used to remove the residue.

In general, large margin can be removed in multi-stroke honing process. Since the single stroke honing process only has one stroke, the margin removal mainly depends on multiple axes. The margin processing capacity of the single stroke tool is shown in the following table.

| Honing stones-Grit | Honing allowance(mm) |

| D1-700# | 0.03~0.13 |

| D3-100# | 0.03~0.10 |

| D5-220# | 0.01~0.08 |

| D7-320# | 0.01~0.06 |

| D8-400# | 0.001~0.013 |

| D0-600# | 0.0006~0.005 |

| D00-1200# | 0.0006~0.0013 |

As can be seen from the table, the higher the mesh number of tools, the higher the surface roughness achieved, but the less the machining margin. Therefore, in general multi-axis configuration, the single stroke tool is selected from coarse to fine. The first few are mainly used to remove the allowance and correct the pass, while the last few are mainly used to improve the surface finish and further correct the pass.