Solutions for glass edges grinding

The edge grinding process can effectively improve the brittleness of glass, making it more beautiful and safe. Generally speaking, it is sufficient to grind the edges of the glass with a coarse grinding wheel, but the requirements for craft decorations are higher. After rough grinding and fine grinding, the original glass of different shapes and sizes gradually approach the workpiece size and surface roughness required by the customer. More SuperHard has been in glass field for more than 10 years and supplies complete processing solutions for furniture and architecture glass.

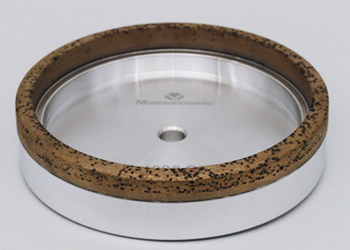

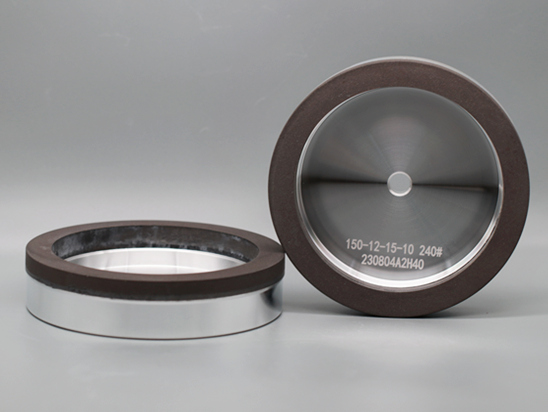

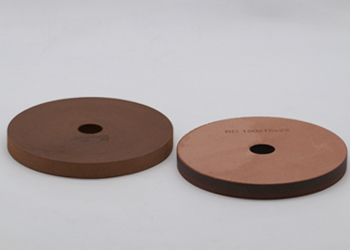

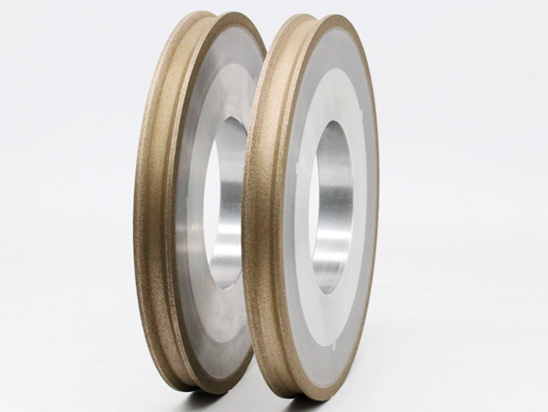

We manufacture Glass Grinding and Polishing Wheels available for use on double straight-line edging machines, bevelling machines, high-speed seaming machines, Profiling machines etc.

After the original glass is produced, the edge of the glass is very sharp and generally needs to be edged. After edge grinding, the glass can play the following roles:

1. Grind off the sharp edges caused by cutting to prevent scratches during use.

2. The small cracks and micro cracks formed by cutting on the edge of the original glass are ground away, eliminating local stress concentration and increasing the strength of the glass.

3. The geometric size tolerance of the glass after edge grinding meets the requirements.

4. The edge of the glass is processed with different grades of quality, that is, it is ground into coarse edge, fine edge and polished edge.

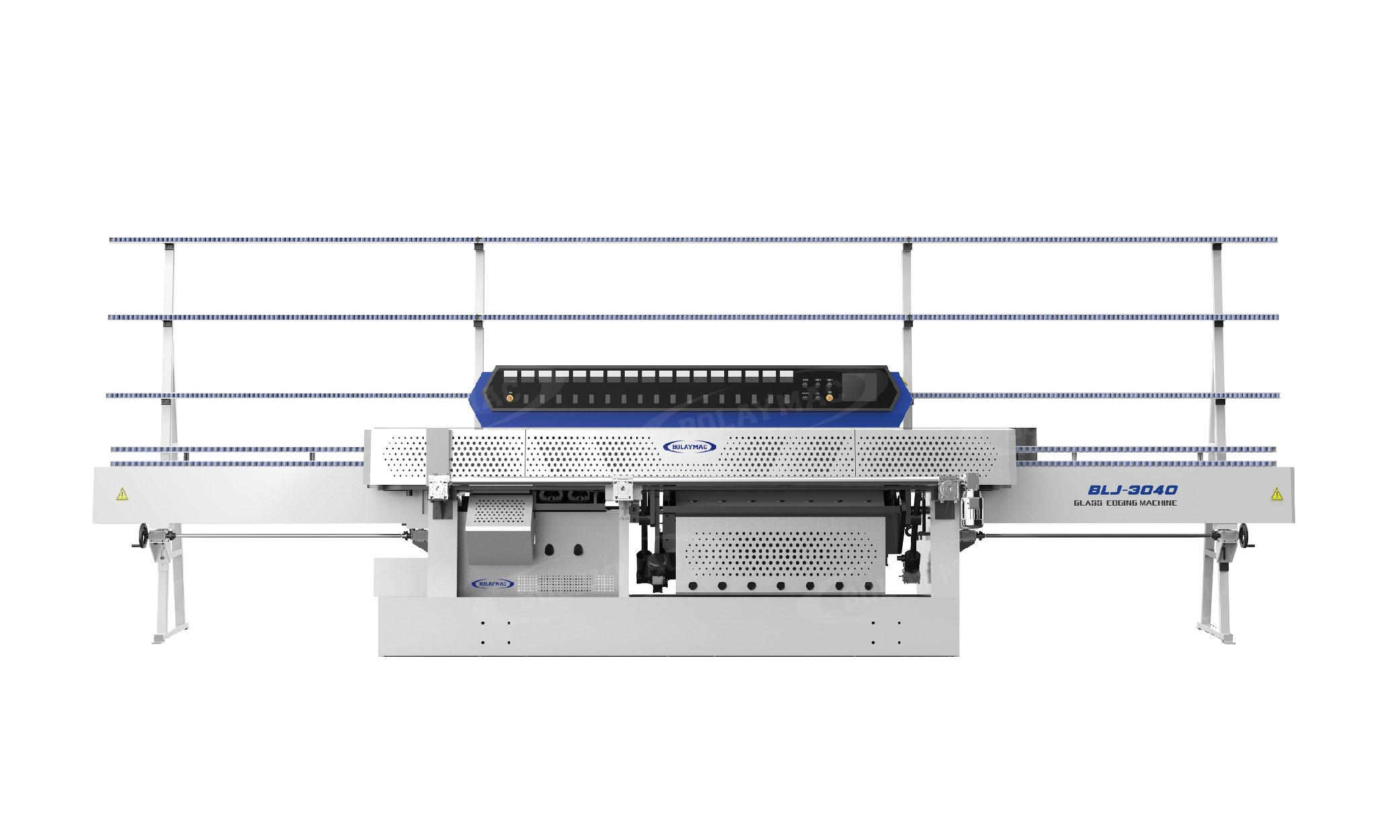

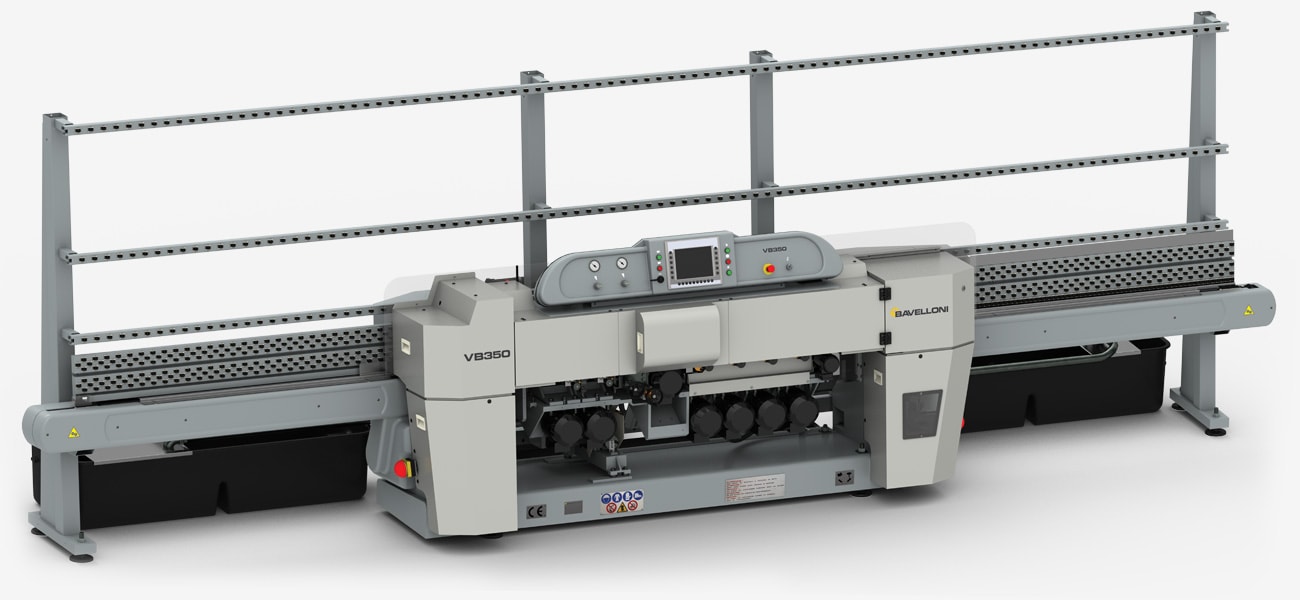

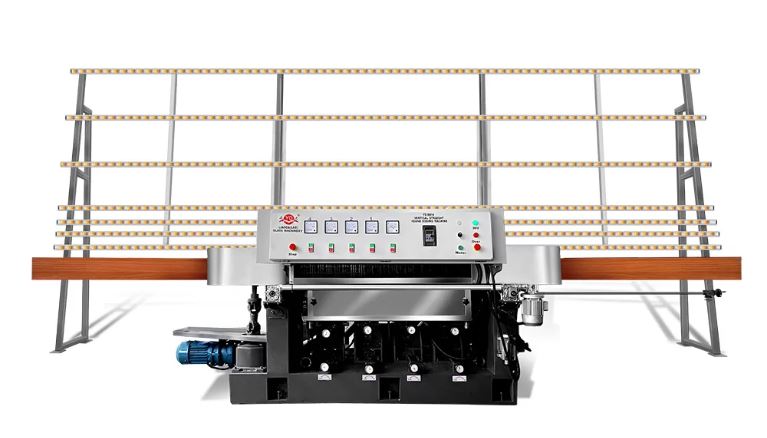

Glass machinery includes: glass edge grinding machine, glass cleaning machine, glass special-shaped machine, glass drilling machine, CNC edge grinding machine, glass tempering furnace, etc. Among them, glass edge grinding machine is divided into: single-sided straight edge grinding machine, beveling machine, double straight edge grinding machine, double round edge machine, etc.

Glass straight edge grinding machine (glass straight edge machine), double straight edge grinding machine:

mainly used for grinding and polishing the bottom edge and edges of flat glass. The processing speed of the single-sided machine is generally maintained at 3-6 meters/minute. The processing speed of the double-sided machine is faster than that of the single-sided one, the conventional one is maintained at 8 meters/minute, and the high-speed one is 12-25 meters/minute.

Glass straight edge beveling machine (glass beveling machine):

mainly used for processing the straight bevel and round bottom edge of flat glass. For the processing of glass products such as mirrors, coffee tables, background walls, etc.

Glass straight edge rounding machine (round edge machine), double straight edge rounding machine:

mainly used for grinding the straight edge round edge, duckbill edge, etc. of flat glass. For deep processing of gas stove panels, range hood panels, dining table panels, etc.

Glass special-shaped edge grinding machine:

mainly used for grinding round and some special-shaped flat glass.

Detailed method of glass edge grinding

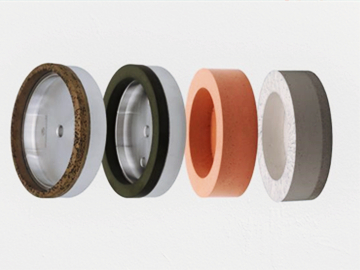

1. First use a metal bond diamond edge grinding wheel to grind, and use coarse, medium and fine grain metal diamond glass wheels to trim the rough shape in turn. It is normal to have broken edges.

2. Then use a resin bond diamond edge grinding wheel to grind into a frosted surface without broken edges. Usually, it can be used after this.

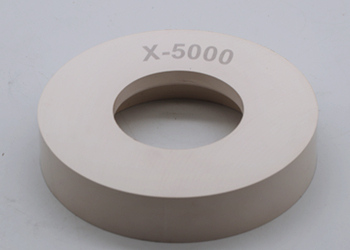

3. Sometimes you want to polish the edge like a mirror. This requires a polishing wheel instead of diamond. Use low-hardness polishing abrasives such as iron oxide and cerium oxide.

In the second step, if you use 3000# for water grinding, the edge of the glass will be almost transparent.

There is a special glass edge grinding machine, which has all the necessary wheels installed (the one with 5 types of wheels is called a 5-head machine, the one with 9 types is a 9-head machine, and so on). The glass is pushed in from one side, passes through all the wheels one by one, and comes out of the other side of the machine as bright as a mirror.

If there is no special machine, if you use a grinder to grind, directly use a 60-mesh metal-bonded diamond edge grinding wheel to grind out the shape, and then use a 150~325-mesh resin-bonded diamond edge grinding wheel to grind away large scratches, so that it can be used almost. If you want a transparent and smooth edge, then use a polishing wheel.

The following situations often occur during glass processing: uneven chamfering, uneven grinding, edge collapse, angle collapse, indentation, scratches and other defects. Do you know the causes and solutions of these defects?

1. Edge grinding has lines and burnt edges

Reason 1: The glass runs too fast.

Solution: Adjust the belt transmission speed according to the thickness of the glass, and do not blindly pursue speed.

Reason 2: The grinding ratio of the grinding wheel is not reasonably configured. The particle size of the first grinding wheel is too coarse, and the lines left behind are difficult to grind flat by the subsequent grinding wheel.

Solution: Adjust the particle size configuration of the diamond wheel and resin wheel, and add a professional scratch removal fine grinding wheel before the water corking wheel to effectively solve the line problem.

Reason 3: The cooling water pipe is blocked, the grinding point is not aligned, or the cooling water is insufficient, resulting in insufficient water pressure and failure to cool the grinding wheel.

Solution: Clear the water pump, water distribution pipe, grinding wheel water pipe and other debris and glass powder sediment.

2. White grinding lines or shiny ripples appear on the edge of the glass

The reason for white grinding lines is: the pressure of a certain polishing wheel is low, the reason for shiny ripples is that the pressure of the polishing wheel is too high. If the polishing wheel material is hard, this phenomenon is likely to occur.

Solution: Adjust the pressure of the polishing wheel; and use a flexible polishing wheel. Generally speaking, good polishing wheels are relatively elastic and not very sensitive to pressure.

3. Laminated glass has irregular grinding patterns

Reason: There is interlayer glue on the grinding wheel.

Solution: Trim the grinding wheel.

4. Glass edge cracking

Reason 1: Too much grinding.

Solution: Reduce the grinding amount.

Reason 2: The edge margin of the glass is too large or the conveying speed is too fast.

Solution: It is recommended to reduce the glass margin by 1-2mm on one side, and adjust the conveying speed of the belt according to the glass thickness and polishing requirements.

Reason 3: Insufficient cooling water.

Solution: Check the cooling system, remove debris such as water pumps, water distribution pipes, grinding wheel water pipes, and glass powder sediment.

Reason 4: The angle of the diamond wheel is not correct or sharp.

Solution: Replace the diamond wheel or adjust the angle. The front foot of the grinding wheel cuts the lower edge of the glass excessively, and the back foot cuts the upper edge of the glass.

More Superhard can produce diamond and polishing wheels for glass:

Rough Grinding: Metal bond diamond cup wheel for glass, diamond cup wheel, Diamond profile wheels

Fine Grinding: Resin bond diamond cup wheel, diamond wheel for Edging, for Bevelling

Polishing: X3000, X5000,10s,BD,BK,CE3 and felt polishing wheels

—-EDIRTOR: Doris Hu,Anna Wang

—-POST: Doris Hu