The case of Dressing Hob Cutter

| Work piece | Hob cutter |

| Material | High speed steel with titanium aluminum nitride coating |

| Hardness | HRC64-68 |

| Allowance | 0.2-0.3mm |

| Roughness | Ra≤0.2μm |

| Accuracy | The straightness of single tooth top to tooth root is 0.005mm, the straightness of the whole hob is 0.01mm from left to right, and the teeth in the circular direction are equally divided into 0.1mm |

| Other | Grinding surface grain consistent, no burn vibration marks |

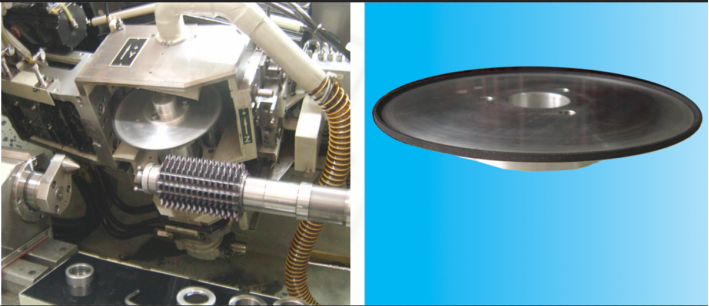

02 Grinding wheel parameters

| Grinding wheel | Grinding wheel for dressing Hob cutter |

| Specification | 4C9 150Dx15Tx3.5Wx50H |

| Bond | Vitrified bond CBN wheels |

03 Machine Parameters

| Machine | LUREN-LHS-3040 |

| Spindle speed | Spindle speed |

| Grinding allowance | 0.2-0.3mm |

| Dressing | WA oil stone 220# |

| Dressing frequency | 1-2 piece/times |

| Feed speed | 600-1000mm/min |

| Dressing time | 25-30 min |

04 Grinding result

| Item | MORE | Top brands in Japan | Note |

| Specification | 4C9

150Dx15Tx3.5Wx50H Vitrified bond wheels |

4C9 150Dx15Tx3.5Wx50H

Resin bond wheels |

|

| Linear speed | 54m/s | 54m/s | same |

| Processing time | 25min | 25min | same |

| Dressing time | Manual | Manual | same |

| Dressing frequency | 1-2 piece/dressing | 1 piece/dressing | |

| Dressing amount | Manual | Manual | same |

| Roughness Ra≤0.2 | 0.08-0.1μm | 0.1-0.12μm | MORE with

better roughness |

| straightness | 0.005mm | 0.005mm | same |

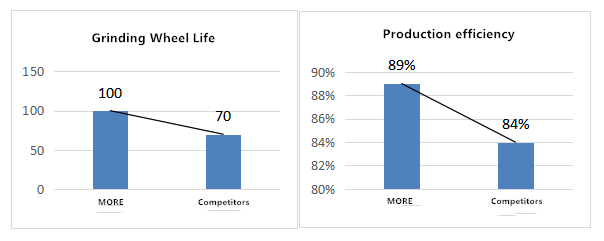

| Life | 100 hob cutter | 70 hob cutter | MORE with longer life |

Through the above cases, we can see that the service life of our grinding wheel increased by 43% compared with the foreign competing grinding wheels under the same processing quality; Production efficiency increased by 5%. the combined cost was reduced by 35%. Our grinding wheels have higher quality and longer service life, which can bring better comprehensive processing cost to customers.