The relationship between grinding wheel wear and feeding speed

We often hear our customers complain that the grinding wheel wear too fast, even they do not change “anything”, same machine, same work piece, same stuff, and same working condition.

Then, what reason lead to this issue?

To solve this problem, we have to check grinding wheel production, status of grinding machine, grinding condition, stability of work piece, etc.

*Reasons of grinding wheel:

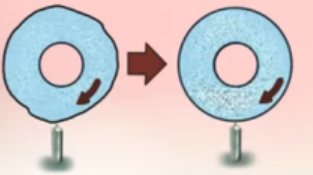

1. Formula of grinding wheel is not suitable

2. Pressure is not enough during grinding wheel production

3. Temperature is wrong

4. Press time is not enough

*Reasons of grinding machine:

1. Run out of main shaft bearing

2. Loosing of transmission mechanism

*Reasons of grinding condition:

1. Grit size not right, too fine.

2. Feeding speed too fast

3. Feeding rate too big

Usually, as customer said “anything” is not changed, same grinding wheel, same work piece, same grinding machine, same stuff and same grinding condition. We think they change a very small thing “feeding speed”. Because they want to improve the grinding efficiency, increase the feeding speed is an easy way.

However, if increase the feeding speed too much, it makes grinding wheel wears out very quickly. The grinding efficiency is improved, but grinding wheel wears too fast. We recommend customer choose a reasonable feeding speed. That’s not a big problem, but it makes your production cost increased.