What is manufactured oil stone made of?

what is the use of oil stone?

Oil stones are used for grinding tools and parts, and can be installed in honing for ultra-finishing. Whetstone can be divided into man-made and natural. Most of the oilstones on the market are man-made. Some inferior whetstones have the disadvantages of poor strength and hardness, are not sharp, and are not wear-resistant, so users must choose wear-resistant whetstones when choosing whetstones. What I want to introduce to you today is the manufacturing process of artificial oil stone.

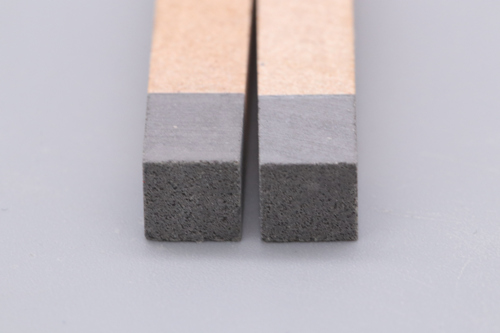

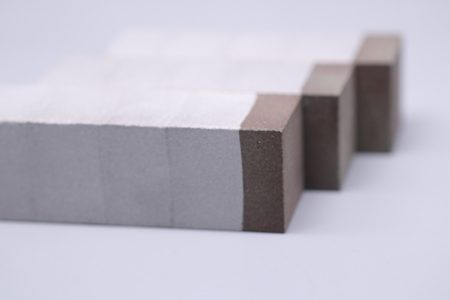

- Oil stone blank

Mix and stir the white corundum micropowder containing impurities and the reinforcing resin binder to form a mixed solution and then pour it into the filter tank. The filter tank is provided with at least two layers of filter screens. Along the filtering direction from top to bottom, the filter screen Mesh holes gradually become thinner, the coarser mixture in the mixed solution stays on the upper filter net, the finer mixture stays on the lower filter net, and the impurities of the white corundum micropowder in the mixed solution flow out with the remaining liquid substances The filter tank, thereby forming a layer of rough oil stone to be sintered on each filter screen.

- Cutting/ Hardening

After the oil stone blank is obtained, the oil stone blank is cut into strips, and soaked in a hardening mixed solution composed of industrial alcohol, fireproof phenolic resin and sulfur with a mass percentage greater than or equal to 95%, for hardening treatment. The hardened mixed solution also includes Acrylic paint, which has the preset color required by the whetstone, and the mass ratio of the acrylic paint to the sulfur is 2-4:1.

-

Baking

The oil stone rough cut into strips is soaked in the hardening mixed solution for 8-15 minutes, and then taken out and baked for the first time. Sufficient immersion makes the first base of the oil stone fully contact with the hardening mixed solution, so as to achieve the effect of enhancing the hardness of the oil stone.

After soaking, the strip-cut oilstone blanks enter into a baking device through a conveying device, and an infrared pre-baking device is arranged on the device. Pre-baking before entering the baking device makes the oil stone green body more evenly heated.

(The first baking) The temperature is 120 degrees Celsius, bake for 1.5 to 3 hours. The strength of the oilstone green body is enhanced through the first baking.

The at least two layers of filter screens are twelve layers, and the mesh fineness of the filter screen from top to bottom is set as: 140-160 mesh, 160-200 mesh, 220-260 mesh, 300-340 mesh, 380- 420 mesh, 580~620 mesh, 780~820 mesh, 900~1100 mesh, 1000~1400 mesh, 1200~1800 mesh, 1800~2200 mesh and 2800~3200 mesh. Since the mesh from top to bottom becomes finer and finer, mixtures of different particle sizes can fall on different filter screens to form the rough oil stone.

-

Second bake

After the first baking of the strip-cut rough oil stone, it is soaked in the wax mixed solution mixed with sulfur, xylene and palm wax according to the mass ratio of 1:6~8:2~3 for 1~5 After a few minutes, take out and bake for the second time. The wax mixture enhances the color of the asphalt preform.

The second baking temperature is 150-250 degrees centigrade, and the baking time is 8-10 hours. Further describe the strength and hardness of the first blank of the whetstone to obtain the finished whetstone.

Classification of oil stone

- According to the molding process, oil stone is divided into natural and artificial:

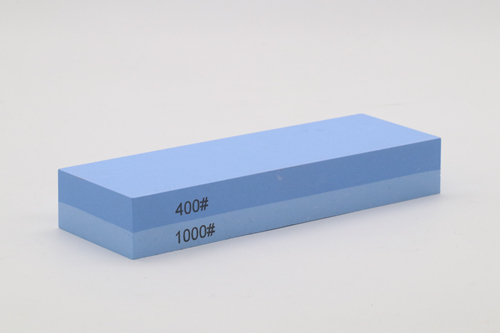

(1) Non-matrix oil tones made of corundum or silicon carbide abrasives and binders can be divided into square, rectangular, triangular, knife-shaped (wedge), round, and semicircular whetstones according to their cross-sectional shapes.

(2) Whetstones with a matrix made of diamond or cubic boron nitride abrasives and binders, including rectangular, triangular, and arc-shaped whetstones.

(3) Natural oilstone is made of natural quartzite with fine texture and grinding and polishing ability. It is suitable for manual precision grinding in the manufacturing industries of precision machinery, clocks and tools.

- Divided by material:

(1) Diamond oil stone: It has the advantages of good elasticity, cutting force and wear resistance. It is the most ideal surface for mold manufacturing, tool repair, various workpiece bends, holes and ordinary abrasive tools. Abrasives cannot be replaced by other oilstones, and the price is only one-third of that imported from abroad. The specifications are 100*2-10*0.5-1.2, and the particle size is 320#-1200#.

(2) Ordinary oilstone: widely used in machinery manufacturing, mold manufacturing, instrumentation and other fields.

(3) Super fine grinding oil stone: super fine grinding oil stone, powerful grinding oil stone, widely used in machinery manufacturing, mold manufacturing, instrumentation and other fields. The work efficiency is twice that of ordinary oilstone.

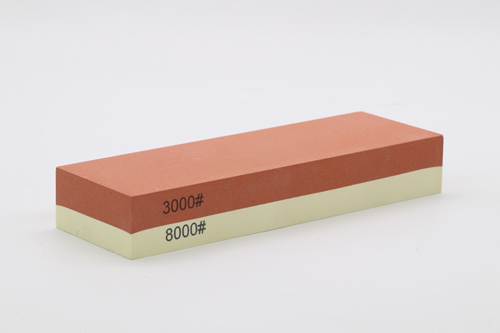

(4) Ruby oilstone: Ruby is a kind of corundum microcrystal formed by sintering alumina powder at high temperature. The structure is compact and delicate, with high hardness and strength. Because it is a sintered product, it does not have various hardness grades, particle sizes and different strength ranges, but it has a dense structure and a pore structure, so the product marks the organizational structure and the product is rose red.

(5) Boron carbide oil stone: boron carbide is a hard black shiny crystal. Hardness is lower than industrial diamond, but higher than silicon carbide. The grain size of the oil stone is between 400 and 1000, the smaller the grain size, the rougher, the greater the grinding amount, and it is used for grinding semi-finished tools. Because of its strong hardness, it is particularly wear-resistant and not easy to scratch.

Operation method of oil stone

- Apply coarse W40 abrasive paste on the boron carbide oil stone, which can speed up and increase the amount of grinding without annealing.

- After cleaning the coarse abrasive paste on the knife, use W0.5 abrasive paste and apply it on ruby or natural jade for polishing. The effect of throwing out is a mirror surface.

- Green silicon carbide, white corundum, and brown corundum oil stones are not hard enough, and the particle size is a bit coarse, so it is easy to grind the knife horizontally, and the other three oil stones will not be annealed during polishing and grinding .

- There is no difference if the particle size is greater than 1000. It mainly depends on the grinding paste used. Apply W1.5 grinding height to 1000 mesh ruby, and its grinding effect is the effect of W1.5 grinding height, that is 2500 grit whetstone effect.

How to clean the oil stone ?

Most of the whetstones are used in mechanical grinding. When it is used repeatedly for a period of time, a lot of dirt will accumulate on the surface of the product. If it is not washed off in time, it will affect the normal use of the whetstone, which is very serious. Therefore, each type of oilstone must be cleaned after being used for a period of time.

Bearing ring grinding, how to choose oilstone?

When superfinishing, what kind of oilstone to choose is very critical. Whether the choice of oilstone is correct or not has a great influence on the quality of superfinishing, production efficiency and production cost. Superfinishing is a low-speed, low-temperature, low-pressure micro-grinding process. The whetstone is not trimmed during work, but its processing characteristics must be maintained during cycle processing. Therefore, the whetstone must have both cutting performance and smooth polishing performance… The factors that determine the performance of oilstone are abrasive, abrasive particle size, binder, structure, hardness and hardness uniformity.

- Abrasive for oilstone

Abrasives for making oilstone include WA, GC, SC, WA/GC (mixed abrasive), WA/SC (mixed abrasive), WA/C (graphite oilstone), etc. WA/GC (mixed abrasive) WA/SC (mixed abrasive) is commonly used in the bearing industry.

- The particle size of the abrasive

There are 14 grades of fine powder particle size for making whetstone, W63~W0.5. The micropowder size used in the super oil stone used in the bearing industry is generally between W2.5~W28. The coarse-grained cutting ability is strong and the production efficiency is high; the fine-grained cutting efficiency is low and the production efficiency is low, but the surface roughness is low. There is a certain relationship between the particle size of the micropowder and the surface roughness, see the table below.

| Abrasive Grit | W28 | W20 | W14 | W10 | W7 | W5 |

| Abrasive Size | 28-20 | 20-14 | 14-10 | 10-7 | 7-5 | 5-3.5 |

| Roughness(Ra) | 0.10-0.15 | 0.08-0.12 | 0.05-0.08 | 0.025-0.05 | 0.02-0.025 | 0.012-0.025 |

| Machining Allowance on Diameter | 12-16 | 10-12 | 8-10 | 6-9 | 5-8 | 3-5 |