What Do You Know About Dynamic Balance of Grinding Wheel?

With the development of science and technology, people’s demand for precision grinding and ultra-precision machining is higher and higher. Grinding is an important means to improve the machining accuracy of the workpiece, and the balance state of the grinding wheel is the main reason to restrict the grinding accuracy. On the one hand, it is reflected in the fluctuation of cutting feed and cutting force caused by the grinding wheel wear of the grinding machine, so that the surface of the processed workpiece produces grinding vibration marks. The most direct effect is to increase the surface roughness value of the processed workpiece, which is a very fatal effect for the grinding process.

As is known to all, grinder is an essential working mother machine for precision machining. In order to adapt to the increasingly precise requirements of working precision and the continuous pursuit of high efficiency and low cost, the global grinder manufacturing industry is making unremitting efforts to improve the geometric accuracy, rigidity and performance stability of machine tools.

And the grinding wheel is the necessary tool of the grinding machine. In order for the wheel to produce accurate size and smooth surface, it is necessary to prevent vibration during grinding. The structure of grinding wheel is composed of a large number of particles with uneven distribution. Inborn unbalance can not be avoided, which will inevitably cause some eccentric vibration. The installation of the wheel’s eccentricity, the uneven thickness of the wheel, the imbalance of the spindle and the grinding wheel’s absorption of coolant will make the vibration increase. These vibrations not only affect the processing quality of the grinding machine, but also reduce the service life of the grinding spindle and grinding wheel, increase the number of grinding wheel correction and the consumption of dressing diamond.

In addition, grinding wheel vibration will also affect the shape accuracy and position accuracy of the processed parts, such as roundness, cylindricity, flatness and so on. On the other hand, the grinding wheel vibration of grinding machine will force the spindle vibration, which will cause uneven bearing stress concentration, thus reducing its service life. In addition, the grinding wheel vibration will force other parts of the machine to vibrate. These vibrations will not only reduce the life of the grinding machine, but also reduce the surface quality of the processed workpiece. It will also produce noise pollution, so that the operator is in a bad working environment.

The unbalance of grinding wheel in grinding process mainly consists of two parts:

First, the static unbalance of the grinding wheel before installation can be adjusted by the relevant static balance instrument, which is very easy to eliminate.

Second, dynamic unbalance of grinding wheel, grinding wheel dynamic imbalance is mainly due to the grinding wheel working at high speed due to grinding machine related spare parts in the process of vibration and wear of grinding wheel’s own cause, because of the imbalance in the process of grinding are changing all the time, so the grinding wheel dynamic balance is evident on the grinding machine grinding is especially important.

First of all, let’s understand the accuracy level of dynamic balance:

Considering the advanced technology and economic rationality, the International organization for Standardization (ISO) developed the world recognized ISO1940 balance grade in 1940. It divides the rotor balance grade into 11 levels, each level is increased by 2.5 times, from the highest requirement G0.4 to the lowest requirement G4000. The unit is gram × mm/kg (GMM /kg), which represents the eccentric distance of the unbalance to the rotor axis. This is shown in the following table:

Level of dynamic balance:

| Accuracy class (G) | g.mm/kg | Examples of Rotor Types |

| G630 | 630 | Rigidly installed crankshaft drive parts of Marine diesel engines; Rigidly mounted crankshaft drivers for large four-stroke engines |

| G250 | 250 | Rigidly mounted crankshaft drivers for high speed four cylinder diesel engines |

| G100 | 100 | Crankshaft drives for six – and multi-cylinder diesel engines. A complete (gasoline, diesel) engine for automobiles, lorries and locomotives. |

| G40 | 40 | Car wheels, hoop wheels, wheels as a whole; A driver for an engine used in automobiles, wagons, and locomotives |

| G16 | 16 | Parts of grinders and agricultural machinery; Individual parts of (gasoline, diesel) engines used in automobiles, lorries and locomotives. |

| G6.3 | 6.3 | Parts of grinders and agricultural machinery; Individual parts of (gasoline, diesel) engines used in automobiles, lorries and locomotives. |

| G2.5 | 2.5 | Gears for the main turbine of sea ships (merchant ships); Impellers of centrifugal separators and pumps; Fan; Rotor parts for aviation gas turbines; The flywheel. General parts of machine tools; ordinary motor rotor; Individual parts of the engine for special requirements |

| G1 | 1 | Tape recorders and record player drivers; Grinding machine drive; Small armatures for special requirements |

| G0.4 | 0.4 | Precision grinding machine spindle, grinding wheel and armature, gyroscope |

In simple words, dynamic balancing is used to re-compensate the asymmetric mass distribution on the rotor, which can be achieved through the following points:

1. Add weight, such as a gripping weight block to balance car tires

2. 2. Removal of mass, e.g. by drilling holes

3. Adjust the quality, such as by adding dynamic balance ring, screw

Unbalance is a common phenomenon in rotating bodies. Unbalanced rotation of the object will produce centrifugal force, it will increase linearly with the increase of unbalance, and because of the increase of the speed of the square secondary changes. The faster the rotor rotates, the greater the imbalance. But how did the imbalance come about? How can you measure an imbalance? How can we eliminate the imbalance through dynamic balance? The following is the attempt and efforts in the grinding wheel dynamic imbalance from Moresuperhard Products Co., Ltd.

Development history of dynamic equilibrium of MORESUPERHARD:

MORESUPERHARD has been engaged in fine grinding for many years, from the initial dynamic balance control of G6.3 to G5 to G4 to 2018 due to customer requirements and cooperation, in a short time to find the problem, analyze the reasons, adjust the precision control of grinding machine processing, and update the configuration of the existing dynamic balancing device, the dynamic balance standard control at G2.5.Take our D350 wheel for example:

2014-2017 results of our balanced customer tests

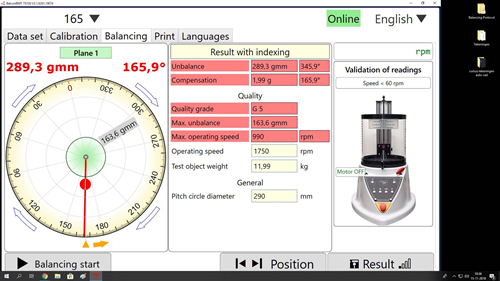

From the above figure, we can see that the customer’s dynamic balancing testing equipment is far better than our existing dynamic balancing machine testing equipment. We can see the test results sent by the customer. We were surprised, and then began to analyze the reasons, deeply reflect on the existing grinding wheel dynamic balance standards, and recalculate the deviations of dynamic unbalance.

The simplified calculation formula of unbalance is: m=9549MG/r×n

M — rotor mass ——unit (kg)

G — Selection of accuracy class

R — Correction radius——unit(mm)

N — Working speed unit of workpiece (RPM)

M — Unbalanced qualified quantity——unit (g)

According to customers with qualified standard of balance, we deduce the dynamic balance of customer standard G5 present, after various research consultancy and study analysis, finally we decided to G2.5 oubiao at that time, to the customer to arrange producing according to the grinding wheel, then send the customer the balance test results for customer to get through:

The grinding wheel dynamic balance is completely controlled in accordance with G2.5 standard, and the accuracy is fully up to the standard. The customer is very satisfied with the grinding effect after receiving the goods. 2018 is a key year for us to improve the dynamic balance, control the width and thickness precision of grinding wheel abrasive layer, control the pulsation and even control the raw material.

With this experience, our main core product vitrified diamond grinding wheel has also started to move towards a new standard and a new height. From the initial G2.5 to the G1 and G0.5 standards in 2020, our wheels can fully meet the G2.5 or even G1 and G0.5 standards by strictly controlling the height of precision, flatness, perpendicularity, concentricity and other shape and position tolerances in the machining and grinding process without making any dynamic balance holes.

MORESUPERHARD will never stop the pace of progress and pursuing high precision. Since the inception, we have always been committed to the vitrified diamond grinding wheel manufacturing, research and development, adhere to the “More Than Grinding” concept, for high precision superhard cutting tool provides the omni-directional “efficient, stable, perfection” grinding solution. In 2020 we conquer ultra narrow layer 1mm wide, 1μm ultra fine-grained grinding wheel production problems, solve the phenomenon of ultra fine-grained abrasive reunion, strictly control the quality of abrasive through the grasp of the abrasive performance, the combination of production and ultra-fine particle size matching agent, debugging formula, optimize the molding process, and combined with the corresponding sintering temperature curve, and with high precision machining, gradually developing and making the series formula of grinding wheel to meet different customers’ market demand such as “916”, “533”, “053”, “253”, etc.