Why choose CBN Grinding Wheel For Gear Hob Grinding ?

The inner hole of high speed steel hob will be deformed after carburizing heat treatment. The unilateral deformation will range from 0.1 mm to 0.25 mm, and the surface hardness can reach above HRC60 degrees.

After heat treatment, the surface hardness of hob is relatively high. Usually, grinding wheel is used for inner hole grinding in the later stage.

General high speed steel hob body is relatively long, the hole is relatively deep (such as hole depth in 150 mm to 200 mm, some may exceed 200 mm depth).

Grinding with corundum grinding wheel will encounter excessive wear of grinding wheel, difficult to master the size, hole grinding out will have the problem of taper.

It is recommended that users use cubic boron nitride (CBN) grinding wheel to grind holes.

Wheel hob grinding inner hole of cubic boron nitride (CBN grinding wheel) there are several different processes of producing method, this is according to customer’s specific process to set, such as the use of grinding machine is high speed or low speed grinder, in theory belongs to low speed grinding machine speed is lower than 10000 turn, more than 40000 to a high speed, another factor is hob grinding inner hole machining allowance and finish requirement.

Different machining processes have different processes of grinding wheel to deal with, there is no general only applicable.

Choosing the wrong grinding wheel will result in low processing efficiency, long processing time and taper of the deep hole grinding.

Our company can provide suitable CBN grinding wheel according to different hob aperture, depth and finish requirements and different types of grinding machines. Welcome to consult.

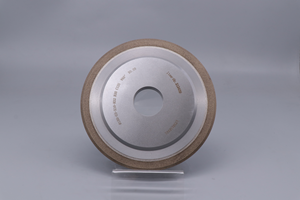

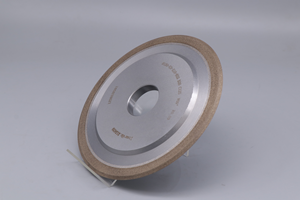

Specifications Of CBN Grinding Wheel For Gear Hob Grinding

| Shape | D (mm) | W | H | X | T | V° |

4BT9 4BT9 |

100 | 10 | 20 | 1 | 10 | 5 |

| 150 | 10 | 50.8 | 3 | 10 | 8 | |

4V4 4V4 |

100 | 6 | 20 | 1 | 10 | 10 |

4C2 4C2 |

150 | 5 | 50.8 | 3 | 20 | — |