Why is there concavity or protrusion on the surface when grinding crankshafts?

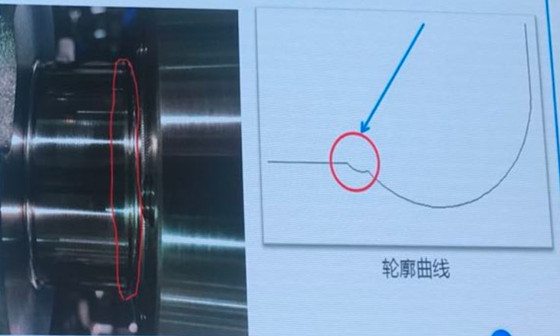

ManifestationsⅠ:

The crankshaft journal has a depression on the edge of the groove

Cause Analysis:

Incomplete when dressing the vitrified CBN grinding wheel。

Solution:

(1)Confirm the position of the grinding wheel and whether the grinding wheel is installed in place After replacing the vitrified CBN grinding wheel.

(2)Adjust the wheel movement control switch to a reasonable position, and confirm that the position of the travel switch is stable.

(3)Adjust the position of the dressing roller and make a mark to prevent the position of the dressing roller from shifting.

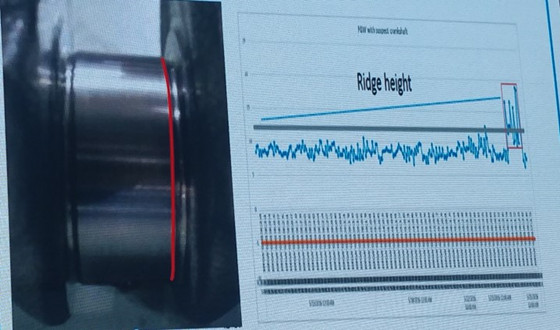

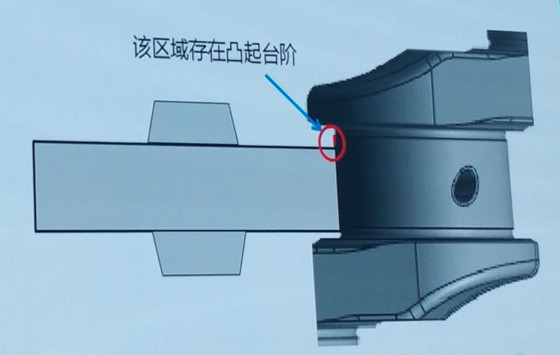

Manifestations Ⅱ:

The crankshaft journal has a protrusion on the edge of the groove.

Cause Analysis:

(1)The vitrified CBN wheel have a collapse.

(2)The axial position of the grinding wheel or workpiece is offset.

(3)Improper rinsing of the grinding wheel causes local abrasive particles to fall off too quickly.

Solution:

(1)Regularly check the surface of the grinding wheel.

(2)Check the position of the grinding wheel to ensure that the dressing surface of the grinding wheel completely covers the journal surface after replacing the grinding wheel.

(3)Confirm the position of the cooling nozzle to prevent improper washing of the grinding wheel causing the abrasive particles on the surface of the grinding wheel to fall off too quickly.