Case of vitrified CBN grinding pins for turbocharger workpiece grinding

What is turbocharger ?

A turbocharger works by taking power from exhaust gases that pass through another turbine that draws in air from a compressor, whereas in a conventional engine the exhaust would be expelled into the atmosphere. More air intake means better mixing of air and fuel during combustion, producing more power with each stroke of the engine.

Moresuperhard meets one customer, who want to grind the turbocharger but have some problems during the grinding process. Let see the grinding solution Moresuperhard provides:

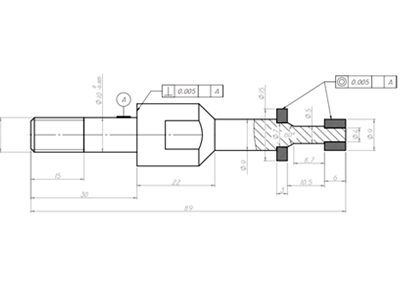

| Workpiece Material | ht250 |

| Surface request | Ra0.4 |

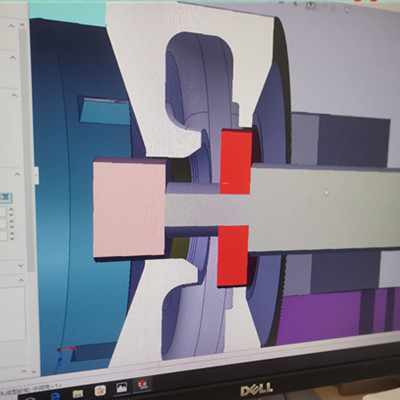

| Problem | There have two different size hole want to grinding.

The efficiency and life of the internal grinding wheel must be considered in combination with the size of the two holes. |

Moresuperhard solutions for our customer:

Solution 1:

Make one vitrified CBN grinding pins with a 9mm diameter. Grinding small holes first and then larger holes.Advantage: Easy to make.Disadvantage: Grinding Wheel will lost shape quickly when grinding the 15.82 mm hole.

Solution 2:

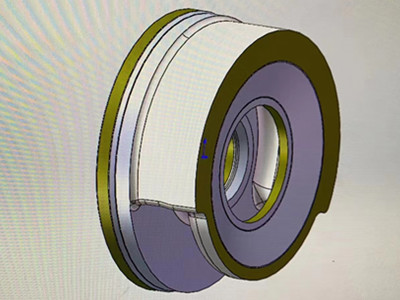

Make two different size vitrified CBN grinding pins in one shank for each hole. 9mm diameter wheel for small hole and 15mm wheel for bigger hole.

Moresuperhard have rich experience in providing grinding solutions for different industries. If you have any requirement about aerospace parts grinding questions, please consult our sales Alan by email at alan.wang@moresuperhard.com.

—EDITOR: Alan Wang/Doris Hu

—POST:Doris Hu