Case of ceramic femur processing customer

Why need to process orthopedic implants?

As the global population ages, the average life span of humans increases, and the incidence of orthopedic diseases increases year by year. The demand for instruments and high-performance components used in surgery has also changed. In view of the human life support properties of the required implants, the demand for The processing quality of the implant material surfaces of the smallest components is particularly stringent, especially when it comes to orthopedic implants, joint replacements and implant material surface processing applications.

Medical implants are mostly made of biocompatible materials, which are difficult to process.

Slight errors in the processing process will have a significant impact on the quality of life. Therefore, the medical industry has increasingly stringent requirements for the reliability, lightweight and compatibility of medical implants.

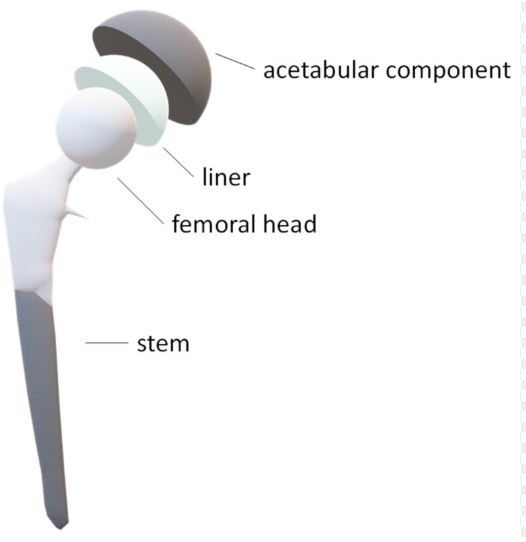

The artificial hip prosthesis mainly consists of the acetabulum, lining, femoral head and femoral stem. It imitates the structure of the human hip joint, inserts the prosthesis handle into the femoral medullary cavity, and uses the head to rotate with the joint socket or prosthetic metal cup to achieve flexion, extension and movement of the femur. Among them, femoral head materials are usually divided into two categories: metal alloys and ceramics.

Features of ceramic femoral head:

➤ Its material is aluminum oxide or zirconia, which is difficult to grind with ordinary grinding wheels.

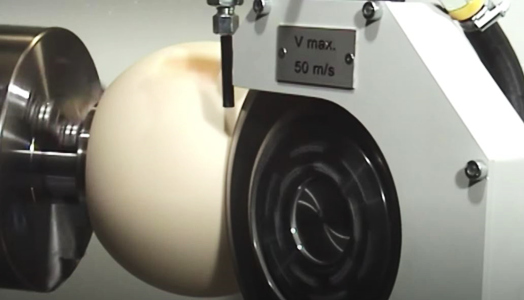

➤ Due to high spherical roundness requirements, the grinding machine tool needs to have spherical grinding function and high precision.

➤ The inner cone surface and the small end surface have transition arc requirements, so the grinding machine tool needs to have multi-axis linkage arc processing functions.

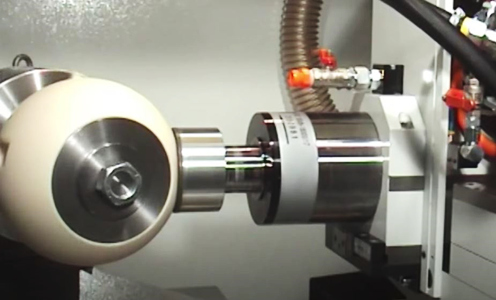

➤ Superhard diamond grinding wheels are used for processing, so the grinding machine tool must have diamond grinding wheel dressing technology.

It is precisely because of the particularity of the ceramic femoral head itself that it puts forward more stringent requirements for grinding processing. STUDER, known for its high precision and quality, has been deeply involved in the field of internal and external cylindrical grinding for many years. It has mature high-precision grinding solutions for the grinding of ceramic femoral heads of hip joints in the medical field. STUDER has also been a world-renowned medical company. A trusted partner for industry customers such as hip joint ceramic femoral head manufacturers. STUDER grinding machines also provide technical support for the grinding of ceramic products with the characteristics of high precision, multi-function, strong versatility, stability and reliability. Moresuperhard diamond grinding wheels can also be matched with STUDER grinding machines to ensure good surface quality of femoral artificial joints.

The current use of ceramic grinding wheels for femoral processing is not suitable, and the first four generations of porcelain can

The fifth generation porcelain has higher toughness and high hardness, and is prone to being unable to be ground. The result is poor and unstable final grinding surface quality.

For ceramic femur processing, Moresuperhard recommends using resin diamond grinding wheel for rough grinding and a resin grinding wheel for fine grinding (resin is easy to repair).

Suggestions of Moresuperhard:

| Grinding method | Grit |

| Fine Grinding | Resin diamond grinding wheel 1500# |

| Metal diamond grinding wheel 1500# |

Case of grinding wheel for ceramic femur :

Requirements of Customer:

| Surface roughness | Ra0.02 | |

| The grinding wheel of customer | Vitrified diamond grinding wheel | They currently use ceramic grinding wheels for rough grinding, and the effect is relatively good. However, the effect of using ceramic grinding wheels for finishing is not good and cannot meet the requirements. |

| Resin diamond grinding wheel | Using 800# resin grinding wheel, the effect is not good and not sharp enough. It is obvious that the grinding wheel is ground by the workpiece, and the abrasive layer visible to the naked eye is ground away by the workpiece. | |

| Metal diamond grinding wheel | The 1200# metal grinding wheel can currently be processed to a finish of Ra0.03, but the grinding wheel is prone to burns. I want to add a cold water tank for cooling and chip removal. |

Moresuperhard is still following up on customer usage, so stay tuned for our follow-up updates.

—EDITOR: Doris Hu

—EDITOR: Doris Hu