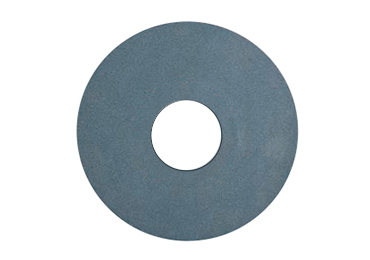

Case of conventional abrasive grinding wheel for crankshaft

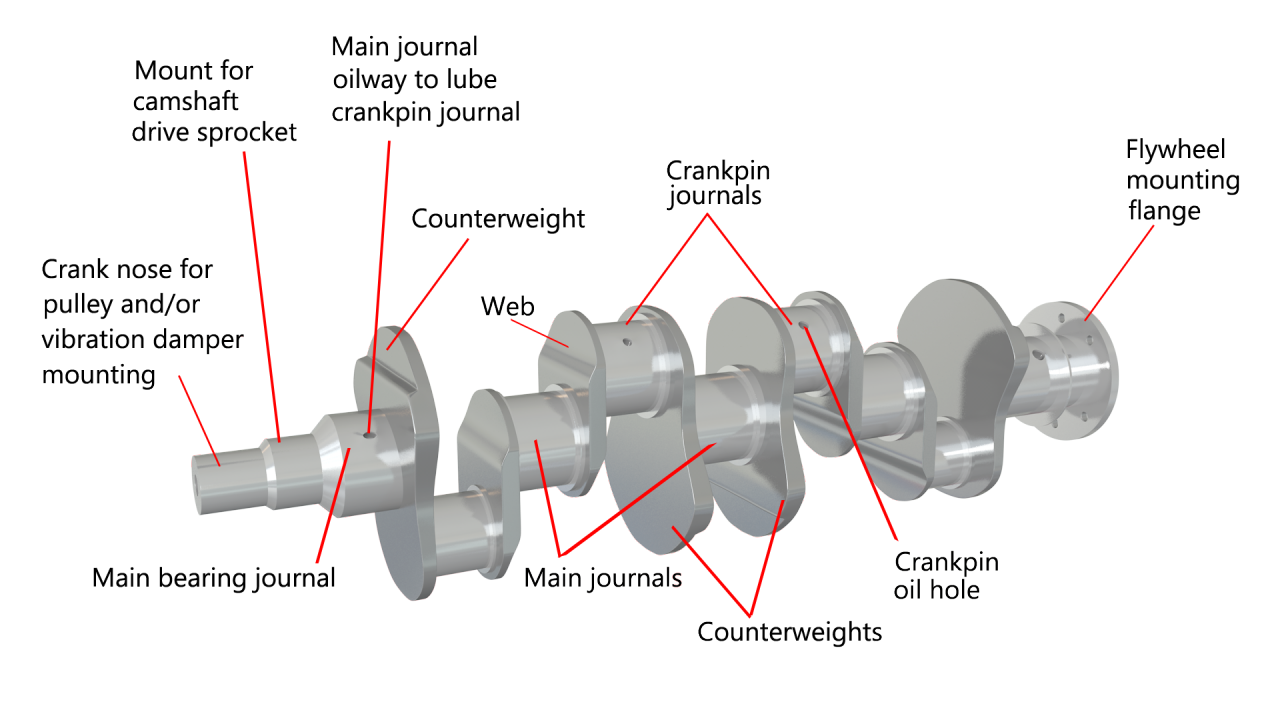

What is crankshaft?

The crankshaft is the most important part of the engine. It bears the force from the connecting rod and converts it into torque to output through the crankshaft and drive other accessories on the engine. The crankshaft is subjected to the combined effects of the centrifugal force of the rotating mass, the periodically changing gas inertia force and the reciprocating inertia force, which makes the crankshaft subject to bending and torsional loads. Therefore, the crankshaft is required to have sufficient strength and rigidity, and the journal surface must be wear-resistant, work evenly and have good balance.

The lower end of the piston’s connecting rod is connected to the crankshaft. When the valve opens and the piston moves downward (inhalation and combustion), the connecting rod drives the raised part of the crankshaft to rotate downward; and when the piston is in the exhaust and compression stages, the connecting rod drives the raised part of the crankshaft to move upward. Due to the design structure of the crankshaft itself, the up and down movement of the piston is cleverly transformed into its own rotational movement, thereby driving the movement of the output shaft.The crankshaft is the main rotating part of the engine. After the connecting rod is installed, it can convert the up and down (reciprocating) motion of the connecting rod into a cyclic (rotating) motion.

The crankshaft is mainly made of carbon structural steel or ductile iron and has two important parts: the main journal and the connecting rod journal. The main journal is installed on the cylinder block, the connecting rod journal is connected to the big end hole of the connecting rod, and the small end hole of the connecting rod is connected to the cylinder piston. It is a typical crank slider mechanism.

Crankshaft main journal and connecting rod journal grinding

The tracking grinding method uses the main journal centerline as the rotation center, and completes the grinding of the crankshaft connecting rod journal in one clamping (it can also be used for main journal grinding). The grinding of the connecting rod journal is achieved by CNC controlling the feeding of the grinding wheel and the two-axis linkage of the workpiece rotation movement to complete the crankshaft processing feed. The tracking grinding method uses one clamping and completes the grinding of the crankshaft main journal and connecting rod journal in one CNC grinder, which can effectively reduce equipment costs, reduce processing costs, and improve processing accuracy and production efficiency.

Crankshaft grinding process

Single-sequence processing method, after the grinding wheel is dressed once, it is processed sequentially. According to the number of grinding wheels used, a single grinding wheel, multiple sets of grinding wheels, and equal sets of grinding wheels can be used. The selection of the specific number of grinding wheel sets is mainly determined by the production cycle. The advantages of single-sequence processing are high consistency guarantee ability of each journal size, easy control of the journal runout after grinding, high processing efficiency, and suitable for mass production; the disadvantages are weak product compatibility and can only process one series of products.

Compound processing can adopt two processes: sequential grinding of the main journal and connecting rod journal and synchronous grinding of the main shaft journal and connecting rod journal. The advantage of compound processing is that the grinding of the main journal and connecting rod journal is completed under the same clamping, eliminating the positioning error caused by clamping, the mutual position accuracy is easy to ensure, the flexibility is high, and it can adapt to the co-production of multiple varieties; the disadvantages are that a single machine tool has a lot of processing content, a single workpiece processing time is long, and the production capacity is not high.

Recently Moresuperhard had one customer who inquired about a conventional abrasive grinding wheel for grinding crankshaft, let’s see it together:

| Machine | BERCO RTM351 |

| Grinding wheel size | 900*16*305 A60NV |

| Abrasive | BA, WA BA/WA |