Case of diamond belt process anti-wear coating

What are anti-abrasion coatings and application?

Friction and wear are ubiquitous phenomena. Whenever the surfaces of objects touch each other and undergo relative motion, friction will exist. Friction must be accompanied by wear. Wear will not only lead to damage and failure of mechanical equipment parts but also consume a large amount of materials. Wear-resistant coating refers to coating a thin layer with friction resistance on the surface of the material substrate so that the surface of the substrate can achieve the purpose of wear resistance. For its preparation and application, the primary performance requirement is to ensure sufficient bonding strength between the coating and the substrate; secondly, to meet the wear resistance of the coating.

Anti-abrasion coatings are deposited on another material, enhance corrosion resistance and improve thermal properties by coating replacement, modification and/or lubrication to give the substrate special properties.

This coating material mainly used in various fields such as aviation, mining, machinery manufacturing and even naval industry.

How to processing the anti-abrasion coatings?

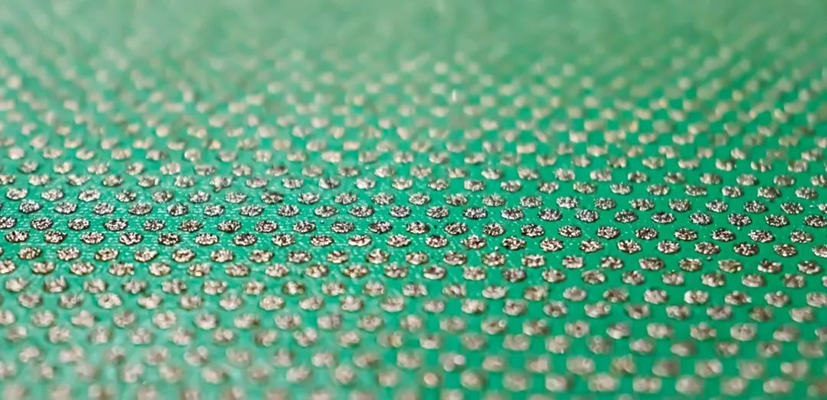

Currently, the most effective way is use diamond sand belt to processing WC-Co or any other high-hardness coating.

Moresupehrard diamond cbn sanding abrasive belt can be widely used for grinding steel, stone, glass, ceramics, monocrystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

Case of diamond belt for anti-abrasion coatings

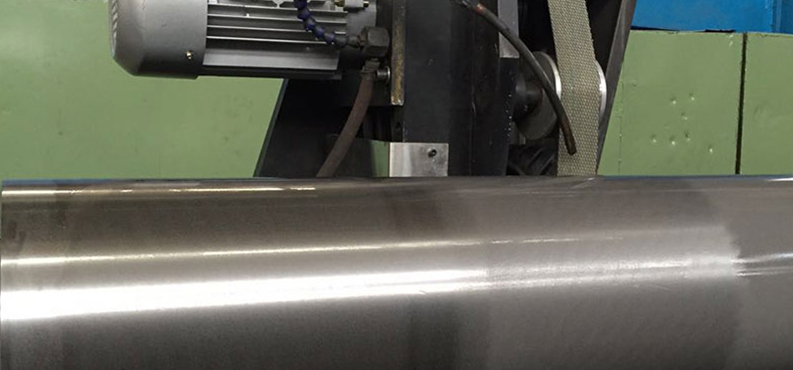

| Workpiece | WC-Co | |

| Machine | Belt machine | |

| Contact wheel | Rubber 90 sh. | |

| Abrasive | Diamond |

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu