Case of diamond core drill bits for sapphire crystal glass

What is glass?

Glass is an amorphous inorganic non-metallic material. It is generally made of a variety of inorganic minerals (such as quartz sand, borax, boric acid, barite, barium carbonate, limestone, feldspar, soda ash, etc.) as the main raw materials and a small amount of auxiliary raw materials are added. Its main components are silicon dioxide and other oxides. The chemical composition of ordinary glass is Na2SiO3, CaSiO3, SiO2 or Na2O·CaO·6SiO2, etc. The main component is silicate complex salt, which is an amorphous solid with irregular structure. It is widely used in buildings to block wind and transmit light and is a mixture. There are also colored glass that shows color by mixing certain metal oxides or salts, and tempered glass made by physical or chemical methods. Sometimes some transparent plastics (such as polymethyl methacrylate) are also called organic glass. Diamond core drill bit are used for drilling glass, ceramics, porcelain, ceramic tile, porcelain tile, limestone, slate, marble, granite, light stone, and fiberglass.

Watches have become an indispensable part of modern people’s lives. They can not only be used as accessories to check time and weather, instant calls, health monitoring, mobile payments, and remote control photography, but some watches even have cultural heritage and craftsmanship value. There are many differences between watches; the most obvious one to the naked eye is the watch mirror. The watch mirror not only sets off the texture of the watch’s appearance and makes it easier for the wearer to read the time, but more importantly, it protects the dial and hands very well.

Watch mirrors are generally divided into three categories: organic synthetic glass, mineral crystal glass, and sapphire glass.

▲ Organic synthetic glass

Commonly known as acrylic glass, it is made of acrylic acid. The hardness of this material is not high and it is easy to scratch, but it has good toughness and is not easy to break. The cost of synthetic glass is low, and many mid- and low-end watches will choose this kind of watch mirror.

▲ Acrylic watch mirror

The acrylic mirror surface has the characteristics of toughness. When it is impacted, it will not produce sharp corners and debris, and it has a certain degree of safety. Therefore, it is more in line with the product requirements of sports watch mirrors. Surface hardening of the acrylic mirror surface can also keep the mirror surface clean for a long time.

▲ Mineral crystal glass

Mineral crystal glass is made of silicon and lead oxide (lead-free crystal uses potassium oxide, barium oxide, etc.) and undergoes a tempering process. Through artificial polishing and grinding, it has high transparency and hardness, which can reach Mohs 7.

The characteristics of this material are that the wear resistance is better than synthetic glass, but inferior to sapphire glass, and it has strong resistance to vertical impact. This kind of watch mirror is mostly used in mid- and low-end watches, and military watches generally use this high-hardness glass.

▲ Sapphire glass

Sapphire glass is made of artificial sapphire crystal. It can generally reach 30% of the watch price as an identifier of top-level watches. The physical and chemical properties of sapphire glass are stable, which can solve problems such as scratches, aging, and corrosion but is fragile.

Sapphire is one of the hardest substances on earth, with a hardness of up to Mohs 9 – second only to diamond in nature. In addition, artificial sapphire glass also has a high light transmittance, which appears very clear and bright in the sun.

Since sapphire has good thermal conductivity, it will feel cool when touched by hand. The sapphire mirror is much smoother than the mirrors of the other two materials. Therefore, if you drop a drop of water on the sapphire mirror, the water drop will not spread easily on it, while the water drop of other materials will spread into one piece.

Diamond is the hardest substance on earth, so diamond drill bits are very suitable for cutting and drilling materials that require high hardness and wear resistance. Diamond drill bits are tools used to drill hard materials such as rock, concrete, ceramics and glass.

Diamond core drill bits generally have two manufacturing processes: sintering and electroplating.

Electroplated bond diamond core drill bits have less abrasive layer and are not durable, but they are sharp. Conventional sintered drill bits are relatively cheap, but if they are used for coring, we support customization if the general size does not meet the requirements.

The abrasive layer of Moresuperhard’s diamond drill bits uses high-quality diamond particles. The abrasives are carefully selected and deeply processed to ensure that the diamond drill bits have excellent cutting performance and durability. The abrasive layer thickness of Moao’s diamond drill bits is usually 1mm, and the diamond layer height is about 10mm. This thin-walled design allows the drill bit to easily penetrate the glass, as easy as cutting tofu with a knife. When using a diamond drill bit to drill glass holes, it is necessary to select the appropriate outer diameter size. When coring, the inner diameter size of the drill bit is more important. In order to obtain high-quality glass holes and cores, suitable coolants are usually used to reduce the drill bit temperature and ensure stable production operations.

The biggest difference between sintered drill bits and electroplated drill bits is durability and sharpness. Sintered drill bits are made by mixing diamond sand and metal powder and sintering them at high temperature to combine them with the matrix.

Compared with the electroplated diamond core drill bit, the sintered diamond core drill bit sharpness is not as good as electroplating, but the products produced by this process have the characteristics of stable quality, durability, and low cost of use. Sintered diamond core drill bits are generally used for machine drilling. The electroplating process is to plate diamond sand layer by layer on the matrix. The products produced have high sharpness and fast drilling speed. The only disadvantage is that they are not durable. The products produced by this process are often used for manual operation.

Diamond core drill bit is one of the high-efficiency abrasive tools specially used for glass drilling and coring. Diamond core drill bit is composed of a steel matrix and a diamond abrasive layer, with excellent cutting force and wear resistance. The design of diamond core drill bit enables it to achieve high precision and smooth surface quality while drilling and coring on glass.

In addition to drilling and coring glass, diamond drill bits are also suitable for other hard and brittle materials such as ceramics, marble, sapphire and other materials.

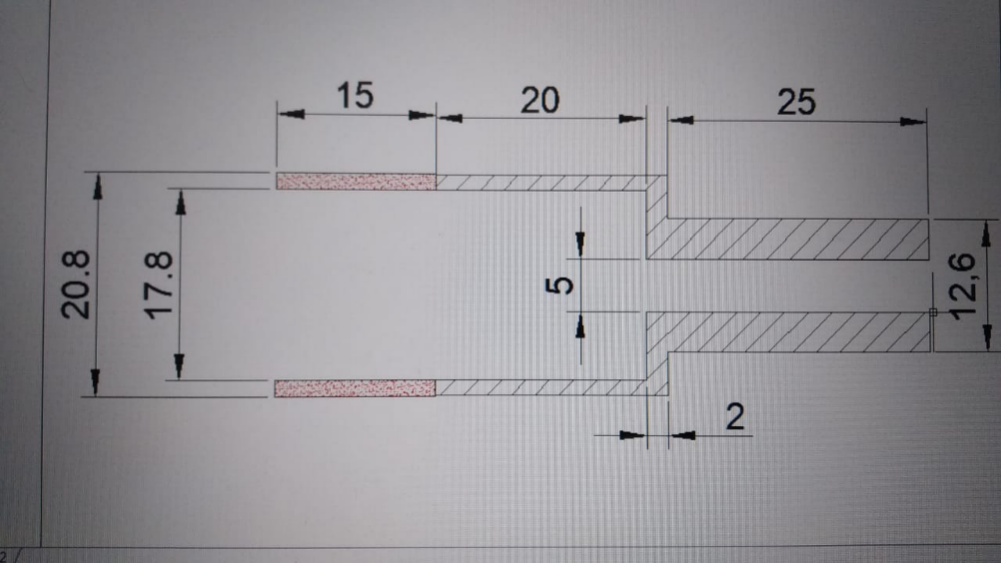

Recently we received diamond drill bits for glass coring from Indian customers. Below is the drawing:

| Requirements of customerC | Cooling is done internal flow of water in adeptor, drill hole 3mm from shaft for water flow,metal bond body part is steel and rough grade. must cut glass fast |

| Workpiece | Crystal glass |

—EDITOR: Doris Hu, Erin Zhang

—POST: Doris Hu