Case of diamond honing reamer for hydraulic valve

What is hydraulic valve?

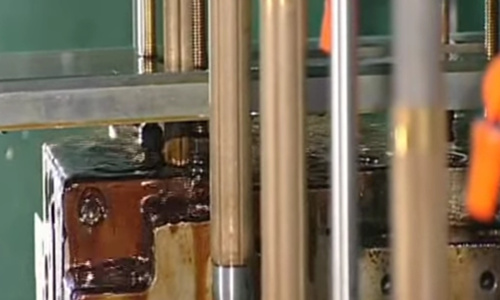

As one of the important geometric surfaces in the hydraulic industry and the automobile industry, the valve hole of the valve body is processed with a diamond honing reamer, also known as a honing reamer, in order to ensure its high precision and roughness. The honing reamer (diamond honing reamer) is mainly used for the finishing process of the valve hole of the valve body. For the machining allowance, several diamond honing reamers are selected to match, and the rough reaming to the fine reaming is completed step by step.

The valve hole can be divided into through hole and blind hole. The diamond honing reamer can also be divided into adjustable and fixed reamers. Among them, the through hole chooses the adjustable diamond reamer, and the blind hole chooses the fixed diamond reamer. The spiral groove or straight groove on the diamond honing reamer is not a chip removal groove.

The chips in the valve hole are washed out by cutting fluid and high-speed rotation. Especially when the machining allowance is large, the heat generated is also relatively large. If the heat and chips are not removed in time, the chips will participate in friction and the cutter body will heat up and expand.

The hydraulics and pneumatics industry is one of the most common honing application areas besides the automotive industry. Performance-optimized surfaces ensure the highest precision for components, improving efficiency and extending component life.

Case of honing parameter for honing reamer for hydraulic valve

| Size | 9.95-10mm and 18.95-18mm |

| Workpiece | Hydraulic valve |

| Hole depth | 100mm |

| Workpiece material | Cast iron and C45 steel |

| Hardness | HB135-180 |

| Surface roughing before honing | Ra1.2 |

| Tolerance | 0.002 |

| Roundness | 0.001 |

| Cylindricity | 0.002 |

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu