Case of diamond polishing film for hard chrome coating solution with Ra0.02

What is roller?

Rollers are important parts of rolling mills in steel mills. They use the pressure generated by a pair or a group of rolls when rolling to roll steel. It mainly bears the dynamic and static loads, wear and temperature changes during rolling.

Rollers are divided into hot rolls and cold rolls.

The materials of working rolls in common cold rolls are 9cr, 9cr2, 9crv, 8crmov, etc. Cold rolls require surface quenching with a hardness of hs45~105.

Common materials for hot rolls are 55mn2, 55cr, 60crmnmo, 60simnmo, etc. Hot rolls are used in billet opening, thick plates, and steel processing. It withstands strong rolling force, severe wear and thermal fatigue, and hot rolls work at high temperatures and allow diameter wear within unit workload, so surface hardness is not required, only high strength, toughness and heat resistance are required. Hot rolls are only normalized or quenched as a whole, and the surface hardness is required to be hb190~270.

When the surface roughness Ra is > 0.01-0.08μm, what are the economical processing methods?

The processing methods are superfine grinding, fine polishing, and mirror finishing.

Customer requirement:

“we want to achieve Ra 0.02 on SS304 roller and we want to procure all tools

and dressing for that.”

Customer existing conditions:

| Workpiece | Hard chrome plated on SS304 roller |

| Roller size | Diameter 650x1050mm |

| Surface roughness | Want to achieve Ra 0.02 |

| Machine | Haas CNC grinder |

| Removal Stock amount | 10 micro |

Analysis by the MORESUPERHARD:

We consider the small removal amount with 10micro and this is the first time the customer to using it, and advice customer to use our Grinding wheel and achieve a fine surface roughness firstly, then fine polishing by film. But we know the Surface roughness approximately is 0.2 micron Ra after hard chrome plating by email. So they don’t need grinding step.

Solutions:

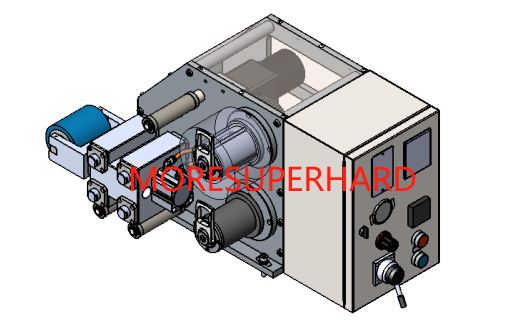

We recommend using 5 different grit 60µm-30µm-15µm-9µm-1µm aluminium oxide polishing film installed on our polishing machine to achieve ra0.02,Moresuperhard both can supply Film polishing machine and film to them.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu