Case of diamond sanding belt for polishing glass bottle gap

Recently, Moresuperhard had a customer who wanted to polish glass bottle gap. Let’s see the details as follows:

Customer requirement:

| Workpiece | The gap in the glass bottle |

| Roughness surface | Ra0.2 |

| Machine | Manual belt sander |

| Grinding condition | Abrasive belt grinding followed by wool wheel polishing |

Customer’s current situation:

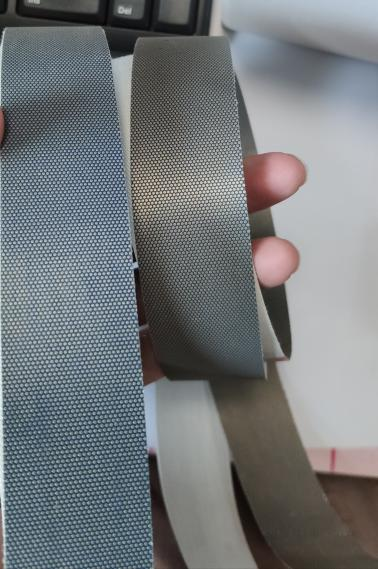

| Sanding belt which customer used before | |

| Abrasive | Aluminium oxide abrasive belt |

| Size | 1200x30mm, 400# |

| Feedback of customer | The processing efficiency is too slow, the customer wants to increase the amount of grinding work-piece per days. |

MORE SUPER HARD Solution to the customer:

Advantages of electroplated diamond abrasive belt:

The gaps between the grinding units arranged in an orderly manner on the working layer of the electroplated diamond abrasive belt form a larger chip space, which is conducive to heat dissipation, and improves the processing quality, flexibility of the abrasive belt and chip removal ability. It also has the environmental advantages of less dust and less noise during use.

Therefore, electroplated diamond abrasive belts are widely used in the grinding and polishing of hard and brittle materials such as glass, stone, ceramics, composite materials, crystal, aerospace, silicon materials, etc.

At the same time, because the nickel plating has a strong holding force on the abrasive, the electroplated CBN abrasive belt can be used for the grinding and polishing of difficult-to-process materials containing iron elements such as steel and ferroalloys.

Let’s see the solutions which Moresuperhard suggest for customer:

| Abrasive of sanding belt | Electroplated Bond Diamond belt |

| Size | 1200x30mm 1000 (soft base) |

| 1600x30mm 1500# (hard base) |

Feedback of customer:

The customer are satisfied with the grinding effect, but there are traces.

Analysis:

The reasons analyzed by the Moresuperhard team are:

the customer grinding amount is relatively small, electroplating bond can remove the stock quickly, but because it is too sharp can not avoid causing scratches.

The next step we suggest the finer grit 2000 and 2500 of electroplated bond diamond belt, or resin bond diamond belt with a soft cloth to the customer, and look forward to the feedback from the customer next time.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu