Case of diamond wet blades for silicon tube

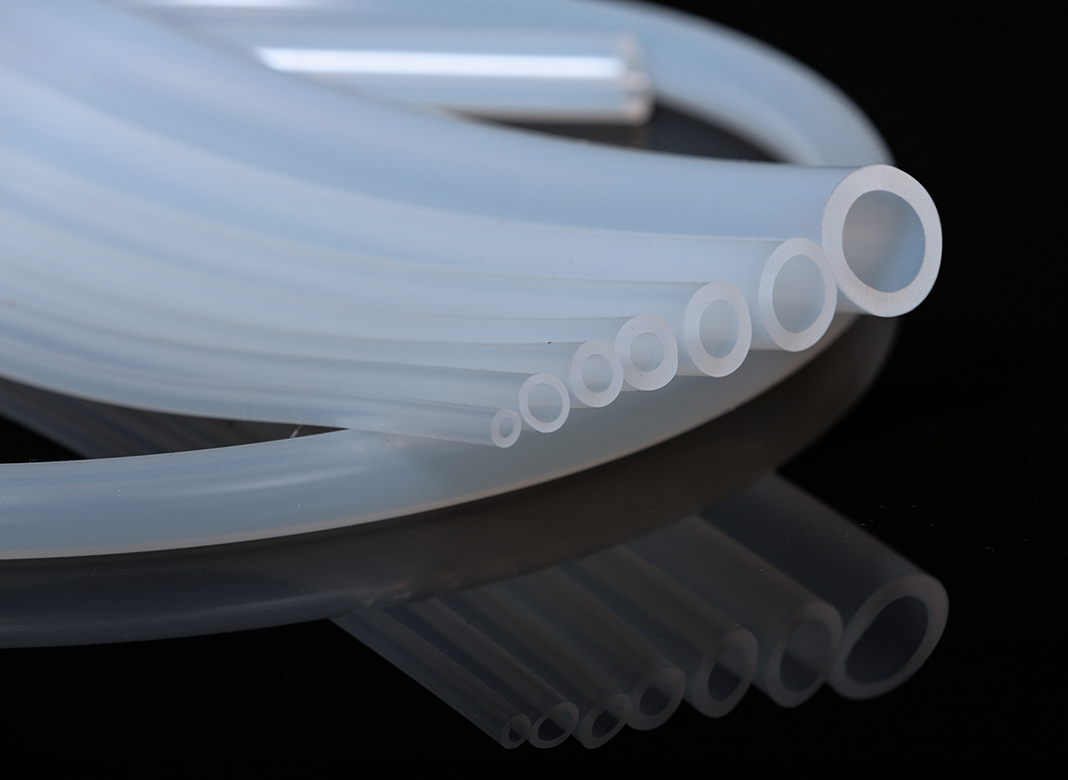

What is silicon tube?

The material of silicone tube has stable chemical properties and does not react with any chemical substances except strong alkali and hydrofluoric acid. Silicon tube has excellent chemical properties, is not easy to age and weather-resistant, has good electrical insulation properties and is soft in material. It can withstand temperatures from minus 40 degrees to about 330 degrees, is colorless and odorless, environmentally friendly and non-toxic. The main application areas are household appliances, industrial industries, medical industries, automotive industries, etc.

At present, there are two kinds of processing of precision glass tubes: one is high temperature with hot processing technology, and the other is precision mechanical shaping with cold processing technology.

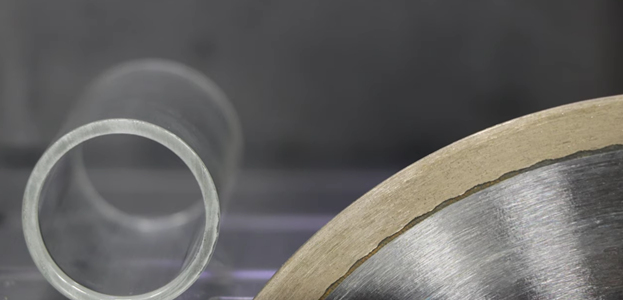

This cold diamond saw features a blade enriched with hard synthetic diamonds to cut through most other softer materials. Water helps ensure a smooth cut along with trapping glass dust (silica) use on a ventilation system.

Smaller tubes need use a score & break technique.

Application of metal diamond cutting disc

Metal diamond cutting disc can be used for general use with ferrous and non-ferrous alloys;copper, aluminum, metal matrix composites,PCB boards, thermal spray coatings and titanium alloy.

Moresuperhard metal diamond saw blades can Cutting: Silicon tube borosilicate tubes over 14mm. Which doesn’t leave the most ideal edge with smooth processing.

This cutting blades should be outside when cutting glass or tile. Eye and Ear protection is also advised for dangerous debris & excessive decibels during the cutting process.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu