Case of electroplated diamond grinding wheels for PEEK material

What is PEEK material?

Polyetheretherketone resin (polyetheretherketone, PEEK resin for short) is a semi-crystalline, high-performance thermoplastic engineering plastic. PEEK has strong mechanical properties, is resistant to chemical corrosion, wear resistance, fatigue resistance and dimensional stability, and is resistant to high temperatures of 260°C. It is commonly used in engineering machinery, aerospace products, etc. According to the editor of Napan New Materials, the upper limit of the use temperature of PEEK and other high-temperature-resistant plastics such as PI, PPS, PTFE, and PPO exceeds 50°C.

Heat resistant

The high temperature resistance of PEEK plastic can reach 260 degrees, and the heat deformation temperature can reach 160 degrees. If modified with 30% glass fiber, its heat deformation temperature can reach 316 degrees Celsius. PEEK resin can still maintain high strength at high temperatures, with a flexural strength of up to 24MPa at 200°C, and a flexural and flexural strength of 12~13mp at 250°C.

Excellent chemical stability

It is resistant to almost all chemical reagents except concentrated sulfuric acid; PEEK’s corrosion resistance is close to that of nickel steel, and it has its own flame retardancy. Peek’s V0 flame retardant grade is as low as 1.45mm, LOI is 35%, and its smoke and poisonous gas emissions are Extremely low. It has excellent hydrolysis resistance and is insoluble in all common solvents. Even in a steam environment of 200-250°C or high-pressure water, it can be used for a long time without significant reduction in performance.

Remarkable tribological characteristics

PEEK has excellent sliding wear resistance and fretting wear performance, especially it can maintain high wear resistance and low friction coefficient at 250℃;

PEEK has greater rigidity, good dimensional stability, a small linear expansion coefficient, and is very close to metallic aluminum materials. Easy to injection molding and extrusion molding, with good processing performance and high molding efficiency.

Because polyetheretherketone PEEK has excellent comprehensive properties, it can replace traditional materials such as metals and ceramics in many special fields. The plastic’s high-temperature resistance, self-lubrication, wear resistance and fatigue resistance make it one of the most popular high-performance engineering plastics today. It is mainly used in aerospace, automotive industry, electronics, electrical and medical equipment, and other fields. Realize “replacing steel with plastic”.

Affected by the lightweighting of new energy vehicles and other industries, polyetheretherketone (PEEK) has become popular recently. Tesla’s electric pickup truck Cybertruck is on sale, and many domestic companies are involved in parts supply. At the same time, Tesla also released the second generation of humanoid robots, which greatly improved its performance compared to the first generation, but reduced its weight by 10 kg. As a high-end engineering plastic, PEEK is 8 times stronger than aluminum alloy and has a density about 1/3 of aluminum alloy. It is very suitable as a lightweight solution in the above fields.

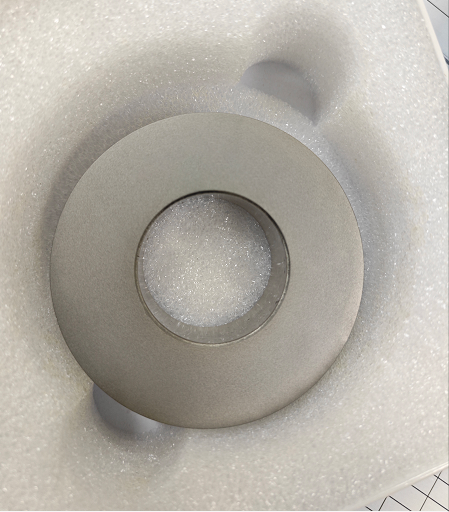

Moresuperhard has developed targeted grinding wheel formulas for the grinding of special engineering plastics such as PEEK, mainly electroplated grinding wheels, divided into rough grinding and fine grinding. Especially for fine grinding, the requirements for grinding wheel accuracy are very strict, such as:

* The grinding wheel flatness is required to be 0.003mm and the parallelism to be 0.006mm.

& Smoothness requirement Ra0.05

Then, we often encounter some problems during processing:

1. During the grinding process of PEEK, how to clean the grinding wheel when the grinding wheel is embedded with powder?

Yes, superhard grinding wheels are generally washable.

2. Can it be cleaned with ultrasonic waves?

no problem

Since its establishment, Moresuperhard has always focused on the research and development and progress of industrial teeth, solving cutting, grinding, and polishing problems in production and manufacturing. It is committed to the manufacturing and sales of diamond and CBN superhard abrasives and continues to provide high-speed, efficient, and Abrasive products that comply with FEPA standards. Provide a complete set of grinding solutions for various fields of industry to help promote Industry 4.0.

Moresuperhard is quality-oriented, adheres to the concept of “creating more value with grinding than grinding”, and provides a full range of “efficient, stable, and ultimate” grinding solutions for high-precision superhard tools. The company also continues to strive for excellence in its products and continues to expand in scale, working together to create a world-renowned brand of superhard products and striving to become a world-class provider of overall grinding solutions.

—EDITOR: Doris Hu, Jim Jiao

—POST: Doris Hu