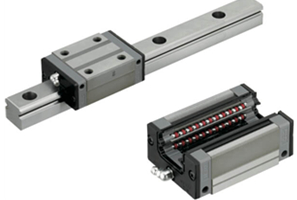

Case of form grinding linear guide

Customer demand:

Improve the grinding wheel life, roughness requirements below Ra0.4, improve work efficiency.

Lets analyse the material of linear guide and grinding wheel for froming grinding:

Material of linear guide:

Linear guide material is S55C, belongs to high carbon steel, has high carbon content, has the advantages of high wear resistance and easy post-treatment.

High carbon steel most often do surface hardening treatment, high carbon steel after heat treatment to improve the strength, become difficult to cut, so when the abrasive strength is not enough, or broken enough, in the grinding process no way to sharpen play a good cutting force.

In addition, the forming grinding wheel load is large, it will produce grinding noise, temperature rise, the surface of the grinding wheel will soon be uneven and other problems, more serious may cause the workpiece burn.

Abrasive

In terms of abrasives, the customer use SA abrasive. Compared with A, WA abrasive , SA abrasive has higher hardness and toughness, strong crushing resistance, more suitable for grinding stainless steel, high-speed steel and other metals with greater toughness.

The S55C used for grinding after heat treatment also has the problem of high hardness workpiece will have large resistance, and the dressing burden on the diamond roller will be relatively large, plus the crushing resistance is strong, although the maintenance force is good, the grinding wheel dressing interval will be relatively shortened.

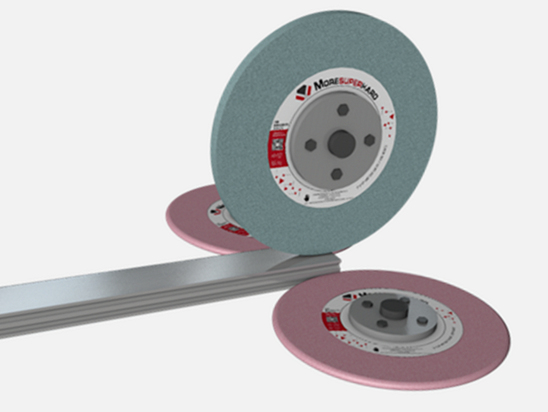

Moresuperhard solutions for satisfy customer:

To solve this customer’s problem, Moresuperhard uses a special SPW abrasive grinding wheel, mixes a variety of alumina abrades, combines the characteristics of different alumina, and makes up for the defects of a single alumina, in order to achieve good shape retention, strong self-sharpening performance, and strong cutting force.

The test results show that, under the same conditions, SPW grinding wheel has a longer life, which can be 3 times longer than SA abrasive. Moreover, due to sufficient self-sharpening performance and cutting force, the dressing interval is also reduced under the premise of greatly reduced surface roughness. It can be seen from the results that SPW grinding wheel mixed with various abrasives is more suitable for forming grinding than general SA grinding wheel.

| Workpiece | S5CC after heat treatment |

| Hardness of workpiece | HRC58-62 |

| Workpiece size | 10*200(cm) |

| Size of SPW abrasive grinding wheel(mm) | 510*15*127 |

| Rotational speed | 900 rpm |

| Feed | 5μm |

| Total grinding amount | 0.05mm |

| Number of grinding workpiece piecs per time | 8pcs |

You can see that the hardness of S55C has exceeded HRC50, which is regarded as a high hardness material. Under the condition of constant processing parameters, because of the good shape retention force of SPW abrasive wheel, the workpiece of single grinding increases from 3 pcs to 8pcs, the total number increases by 3 times, the service life is longer, the dressing times are reduced a lot, and the roughness also decreases by 50%. It can be seen that SPW abrasive is very suitable for forming grinding, with high effect and successful test.