Case of metal diamond honing stick for high borosilicate glass

What is high borosilicate glass?

High borosilicate glass is also called “borosilicate glass 3.3” because its linear thermal expansion coefficient is (3.3±0.1)×10-6/K. It is a special glass material with low expansion rate, high temperature resistance, high strength, high hardness, high light transmittance and high chemical stability. Because of its excellent performance, it is widely used in solar energy, chemical industry, pharmaceutical packaging, electric light source , craft jewelry and other industries. Its good performance has been widely recognized by all walks of life in the world, especially in the field of solar energy.

Application of high borosilicate glass:

High borosilicate glass tube bubble tube application fields

1. Solar power regeneration (solar panel).

2. Chemical machinery and equipment, flanged pipes, instruments and meters (observation window, sight glass, fire viewing hole, instrument panel, etc.).

3. Medical technology and bioengineering.

4. Lighting, ground lamps (high-power spotlights and protective glass for floodlights).

5. Craft jewelry and other industries.

Advantages of metal diamond honing stone:

Metal diamond honing stick: most suitable for processing hard and brittle difficult-to-machine materials, new hard materials such as cemented carbide, optical glass, ceramics, gemstones, stone materials, semiconductors, ferrite, carbide steel, and corundum sintering.

Recently we have had one customer inquiry metal diamond honing stick for honing high borosilicate glass, Sunnen honing machine used by the customer, the size of the whetstone, and the required smoothness R0.1. Honing rod used Sunnen honing rod, let’s see as follows:

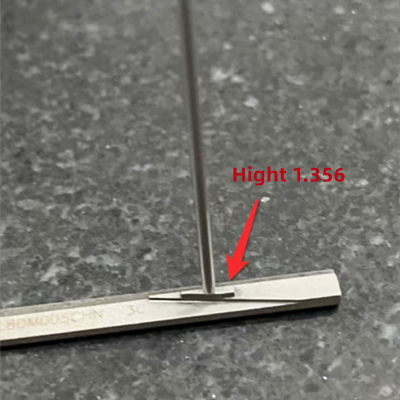

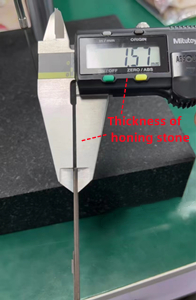

1. Specification of honing stick of customer used before:

Honing rod specification of customer used before:

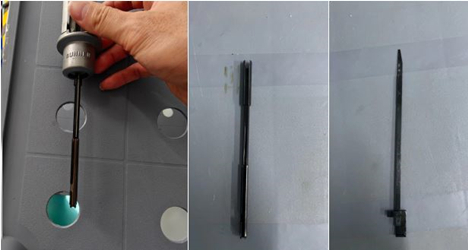

Moresuperhard metal diamond honing stick for high borosilicate glass, has delivery to customer:

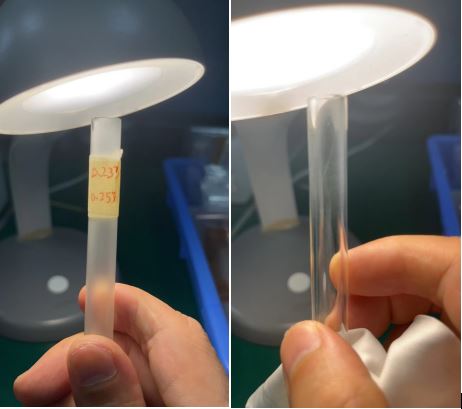

Feedback of customer:

The honing stick is verified on the machine, two glass tubes are produced, and the roughness of the four sections at the two ends is measured. The actual measurement is as follows:

| First test | Ra 0.336μm |

| Second test: | Ra 0.345μm |

| Third test | Ra 0.266μm |

| Last test | Ra 0.216μm |

| Test result

|

After polishing the inner hole, it can be seen that the honing marks on the inner wall are very serious. |

| Analysis: There may be large particles mixed in when mixing the ingredients, and the formula needs to be adjusted, and 2 pieces are re-adjusted for the customer | |

| Grinding feedback | The grinding feedback is as follows: the roughness after fine polishing is 0.233~0.253, which is improved compared to the first time, but still not up to standard. After polishing, the honing pattern on the inner wall turns white and the honing pattern is more obvious. |

Moresuperhard decided to buy finer abrasives and try again, looking forward to our next breakthrough.

—EDITOR: Doris Hu,Julia Zhang

—POST: Doris Hu