Case of resin CBN grinding wheel for processing stainless steel fixture

What is the function of the fixture?

A fixture refers to a device used to fix the processing object during the machinery manufacturing process so that it can occupy the correct position for construction or inspection.. Broadly speaking, in any process during the process, the device used to install the workpiece quickly, conveniently and safely can be called a fixture.

The design of machine tool fixtures is an important part of mechanical manufacturing technology. The fixture is an important part of the mechanical processing technology system and a necessary device to ensure the accurate and stable relative positions of the machine tool, workpiece and tool.

Fixture grinding is very different from precision grinding of cylinders and surfaces. This is because it can produce workpieces with more complex shapes and qualities.

Recently, Moresuperhard have a customer, who want to grinding fixture, lets see the case together:

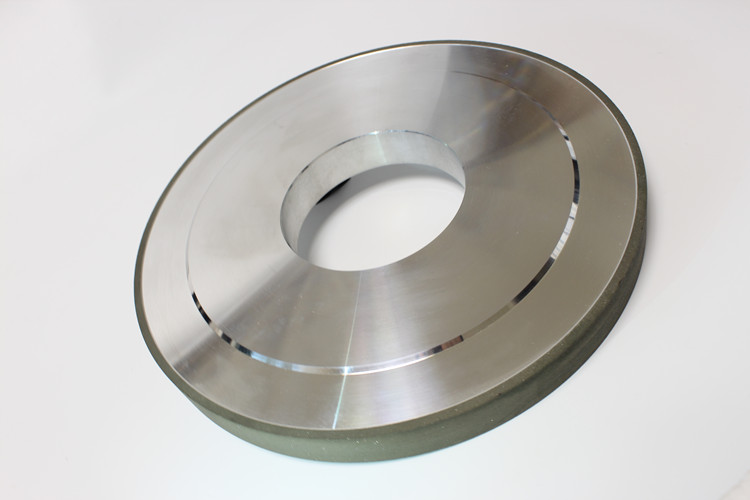

Cubic boron nitride abrasives have high hardness, good thermal stability, and high chemical inertness. CBN grinding wheel do not oxidize at 1300°C to 1500°C. The edges of the abrasive grains are not easily blunted and generate less grinding heat. They are suitable for various grinding applications. Stainless steel. So resin cbn grinding wheel is best choice for grinding stainless workpiece fixture.

| Workpiece material | HSS and stainless |

| workpiece | fixture |

| Workpiece hardness | 58-62HRC |

| Grinding feed | 2μm |

| Grinding method | Surface grinding |

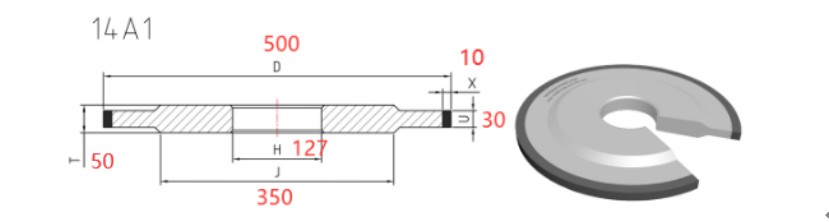

| Grinding wheel size | 14A1 D500xT50xH127xU30xX10mm |

| 100# |

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu