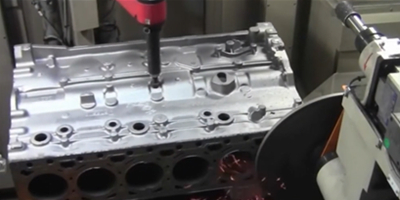

Case of vacuum diamond grinding wheel for grey and nodular cast parts by robot arm

What is ductile iron?

Before pouring molten iron, a small amount of spheroidizing agent (such as magnesium, calcium and rare earth elements, etc.) and graphite agent (such as ferrosilicon, silicon-calcium alloy) are added to the molten iron to promote the existence of carbon in the form of spheroidal graphite crystals. This kind of cast iron is called ductile iron. Ductile iron is much better than gray cast iron in strength, plasticity and toughness, and even close to steel. In acidic medium, ductile iron has poor corrosion resistance, but in other media, it has better corrosion resistance than gray cast iron. Its price is lower than steel. Because it has the advantages of both ordinary cast iron and steel, it has become a new type of structural material. In the past, many important parts made of carbon steel and alloy steel (such as crankshafts, connecting rods, spindles, medium-pressure valves, etc.) have been replaced by ductile iron. Through die-casting, precision parts can be processed, but they cannot be cast. They are fired at high temperatures. Ductile iron is a new sand casting process. The difference from ordinary ones is generally in the texture. It is generally used to produce manhole covers, pipe fittings, etc. Density: Approximately the density of steel.

What is gray cast iron?

Gray cast iron is a type of cast iron, and the internal carbon exists in the form of flake graphite. The fracture is gray, so it is referred to as gray iron.

Grinding is an important part of the production and processing of castings. The grinding wheel is an important cutting tool in the grinding process. If the grinding wheel is not selected properly, it will not only directly affect the processing accuracy and surface roughness of the castings, but also cause the scrap rate of the castings.

Moresuperhard has developed a series of cast iron grinding tools for ball milling and gray cast iron parts. It uses a steel matrix and super-hard diamond abrasives and is made through a brazing process. Vacuum brazed diamond grinding whel has high hardness. Sharp, safe, and environmentally friendly, it is a new generation of green and efficient cutting and grinding tools.

Brazed super-hard grinding wheels have the following characteristics:

① The abrasive, brazing material and substrate can achieve metallurgical chemical bonding, thereby improving the bonding strength and extending the tool life;

② The exposed height of the abrasive grains is large (up to 70% to 80% of the abrasive grain height), the chip space is large, not easy to be blocked, and the abrasive is more fully utilized;

③ Lower grinding force, power consumption and grinding temperature;

④ It has environmental significance and is in line with the current trend of green manufacturing development advocated.

Recently Moresuperhard have one customer who inquiry vacuum brazed diamond grinding wheel for grinding ductile and grey cast iron, let’s see it together:

| Machine | Koyama 400 |

| Workpiece material | Grey and nodular cast GG100-200 in GGG400-600 |

| Workpiece | different cast parts |

| Vacuum brazed diamond grinding wheel size | D:355-12T-31.75 |

| Grit of vacuum brazed diamond grinding wheel | 20/30 |

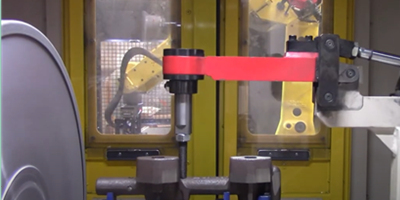

| Grinding method | Auto grinding by robot arm |

—EDITOR: Doris Hu, Alan Wang

–POST: Doris Hu