Case of Vitrified bond CBN wheel for compressor cylinder

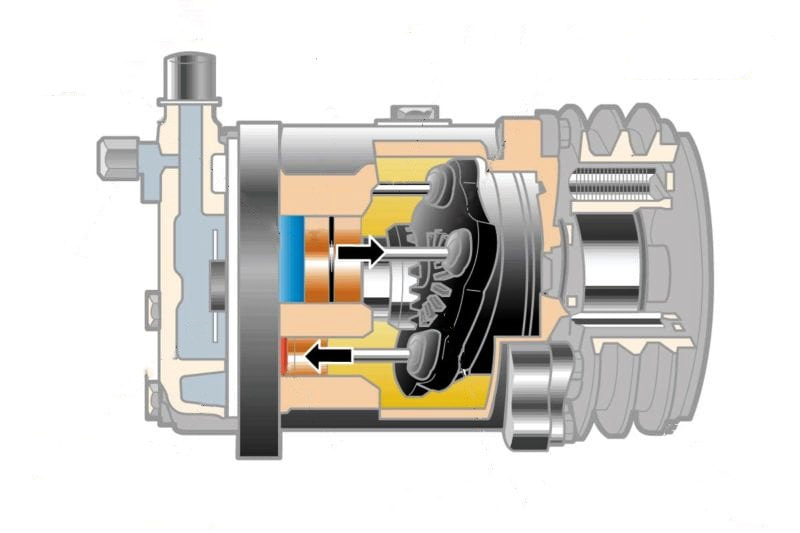

What is compressor cylinder?

The compressor cylinder is fastened to the body of the compressor or the crankcase or the middle body, and the piston is used to compress the gas. Generally composed of three parts of the cylinder head, cylinder body and cylinder seat or two parts of the cylinder head and cylinder body, its main function is: to form a compression volume with the piston and withstand gas pressure; Accommodates a piston in which to perform repeated motion; The valve seal stuffing box is arranged on it.

The basic requirements for the cylinder are:

(1) Have sufficient strength and stiffness;

(2) the surface should have good wear resistance and tightness, and there should be good lubrication in the oil-lubricated compressor;

(3) Good cooling to disperse the heat and friction heat generated when the gas is compressed.

Vitrified bond CBN internal grinding wheels are widely used in air-conditioning compressors, auto parts and other industries, such as compressor pistons, cylinders, cylinder heads, bearings, gears and other internal hole grinding. CBN internal grinding wheel is suitable for various ultra-high precision internal hole grinding, the grinding wheel has an open structure and good self-sharpening.

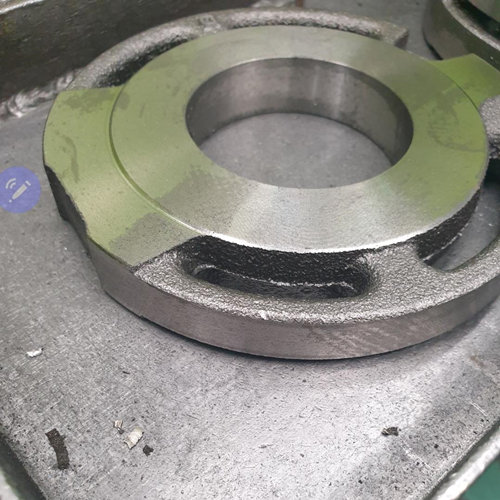

Recently, we have had one customer, who want to grinding compressor cylinder. More details are as follows:

| Machine | Toyo |

| Machine Speed | 20000-25000RPM |

| Dressing Method | Diamond rotary dresser |

| Workpiece | Compressor cylinder |

| Material | FC250 |

| Surface Ra request | Ra ≤0.3 |

| Grinding wheels | Vitrified bond CBN wheel |

| Grit: 140/170 | |

| Size: D33.5xM16 | |

| Hardness: M | |

|

Grinding parameters

|

Allowance:0.2-0.3mm |

| Grinding time: 30ec/workpiece | |

| Step: Rough grinding/Finish grinding/Polishing | |

| Dressing cycle: 110-130 pieces/dressing |

Any requirement about compressor cylinder , welcome to contact our Sales Manager Mr. Alan to inquiry more!

–EDITOR: Doris Hu, Alan Wang

—POST: Doris Hu