Case of vitrified bond CBN wheel for grinding crankshaft

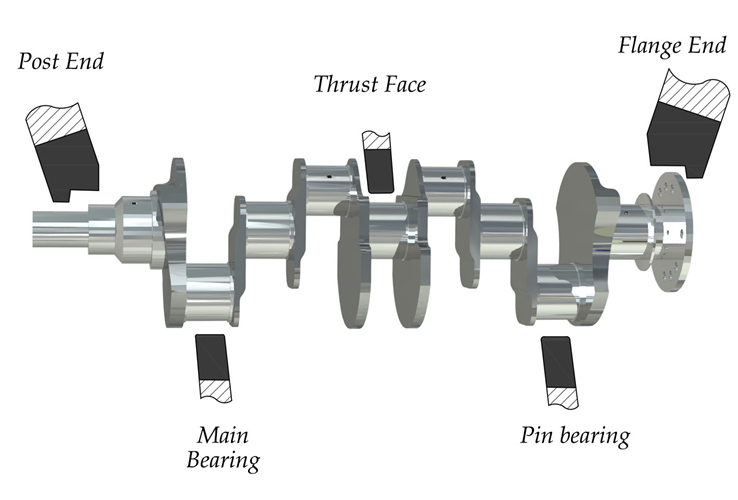

What is crankshaft?

The crankshaft is the main rotating part of the engine. After the connecting rod is installed, it can convert the up and down (reciprocating) motion of the connecting rod into a circular (rotating) motion.

Working principle of the crankshaft:

The crankshaft is one of the most typical and important parts in the engine. Its function is to convert the gas pressure transmitted by the piston connecting rod into torque, output work as power, drive other working mechanisms, and drive the auxiliary equipment of the internal combustion engine to work.

The crankshaft is one of the core components of the automobile engine. The quality of the crankshaft determines the working performance and life of the engine to a large extent, and directly affects the fuel economy of the vehicle and the compliance rate of environmental emissions. During operation, the crankshaft will be subjected to the combined effects of the centrifugal force of the rotating mass, the periodically changing gas inertia force and the reciprocating inertia force, which makes the crankshaft subject to bending and torsional loads. This requires the crankshaft to have not only sufficient strength and rigidity, but also surface wear resistance, uniform operation and good balance. Therefore, the shape profile and roughness have become two key quality indicators of the crankshaft. Therefore, when grinding the crankshaft, choosing a special ceramic CBN grinding wheel can better ensure production efficiency and quality.

The crankshaft is an important part of the engine. It is made of carbon structural steel or ductile iron. It has two important parts: the main journal and the connecting rod journal (and other parts). The main journal is installed on the cylinder block, the connecting rod journal is connected to the big end hole of the connecting rod, and the small end hole of the connecting rod is connected to the cylinder piston. It is a typical crank slider mechanism.

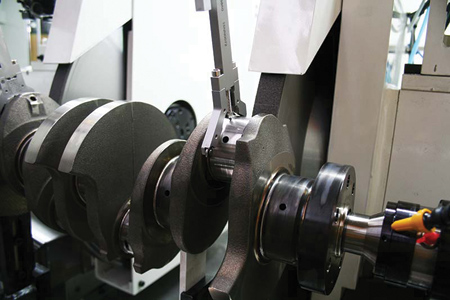

How to grind crankshaft?

The grinding process of the crankshaft is the same as the plunge grinding method of the outer circle. Grind the main journal and its outer circle separately, and then grind the crank neck, shoulder and R arc surface. The grinding force and grinding heat generated during plunge grinding are more than ten times greater than those of outer circle grinding. In order to ensure the machining accuracy of the crankshaft, the grinding allowance should be removed by rough and fine grinding, and sufficient cooling should be paid attention to.

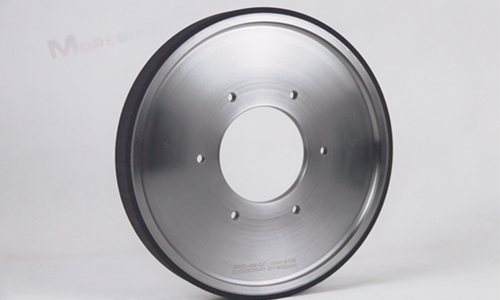

Recently,Moresuperhard has one customer, who inquired about vitrified CBN grinding wheel for crankshaft. Let’s see the reuirements together:

| Wheel size | 750x24x203.2 |

| Stock removal | The overall stock removal is 0.8 mm, but it will be ground in 4 passes. It means about 0.2 mm each pass. |

| Grinding speed | 2,430 rpm. (Vc=75 m/s) |

| Grinding machine | SAIMP machine 2000 |

| Cooling type | neat oil |

| Requested surface quality | Ra 0.4 |

| Workpiece material | Cast Iron (GGG70) |

| Grinding operation | finishing |

—EDITOR: Doris Hu, Alan Wang

— POST: Doris Hu