Case of vitrified CBN grinding wheel for pinion shaft grinding

Why choose vitrified CBN grinding wheel for pinion shaft grinding?

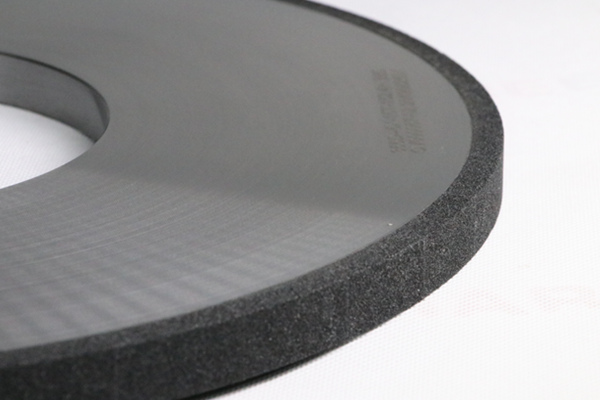

Ceramic CBN grinding wheels are used for machining of various camshafts, crankshafts, gear shafts, and motor shafts. The ceramic bond achieves excellent grinding performance such as high cutting force, good heat dissipation, and high workpiece precision stability, meeting the grinding requirements of various materials.

What is pinion shaft?

The pinion shaft refers to a mechanical part that supports the rotating parts and rotates with them to transmit motion, torque or bending moment. It is generally a metal round rod, and each section can have different diameters. The parts that perform rotational motion are installed on the shaft. In design, the use of pinion shafts is generally the following:

1. The pinion shaft is generally a small gear (a gear with a small number of teeth).

2. The pinion shaft is generally at the high-speed level (that is, the low-torque level).

3. Pinion shafts are generally rarely used as sliding gears for speed change, and are generally fixed gears.

4. The gear shaft is a combination of the shaft and the gear, but the length of the shaft should be shortened as much as possible during design. If it is too long, it is not conducive to the processing of the hobbing machine, and the shaft support is too long, which causes the shaft to be thickened to increase the mechanical strength (such as rigidity, deflection, bending resistance, etc.).

The pinion shaft is one of the most critical parts in the automotive reducer assembly. The performance of the gear shaft directly affects the transmission efficiency and service life of the reducer assembly. In the actual working process, the reducer gear shaft is subjected to large alternating loads such as torsion, bending, compression, and extrusion, and also has to bear the friction of the gears and bearings on the shaft when they are running.

Usually the gear shaft of the reducer is made into a one-piece gear and shaft or part of the gear and shaft are one-piece. There are also gears and shafts that are made separately and assembled into parts after processing. The gear shaft is usually designed as a stepped shaft, which has the advantages of simple structure, simple mold making, easy processing, and low manufacturing cost.

As the fixed shaft of the gear, the pinion shaft plays the role of supporting the gear in the gear. The strength and stiffness of the gear shaft are required to be high to ensure the stability of the gear structure and normal operation. The gear shaft is usually combined with the gear in the reducer for transmission and plays the role of balancing the torque.

The pinion shaft achieves a reduction in speed and an increase in torque through the meshing of different gears. This enables new energy vehicles to provide more stable output and higher efficiency when greater driving force is required.

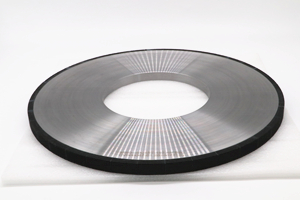

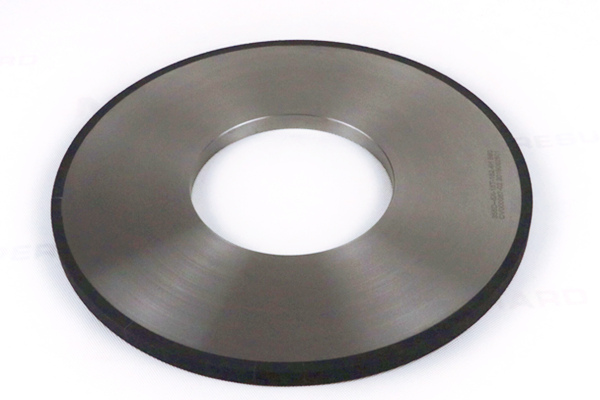

Recently we have one customer who inquired about pinion shaft grinding,Moresuperhard provided vitrified CBN grinding wheel solutions to him,lets see it together:

| Grinding wheel | Vitrified bond CBN wheel | Size | (D610xH254xT23mm) |

| Grit | B64 | ||

| Surface finish request | Ra 0.4 | ||

| Workpiece | For pinion process | ||

| Fluid | Ecocool 7081 | ||

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu