Case of vitrified CBN lapping disc for lapping HSS workpiece

Lapping is a precision machining process that involves the removal of material to achieve high levels of surface finish, flatness, and dimensional accuracy. The choice of lapping disc is crucial, especially when working with materials like High-Speed Steel (HSS). Two commonly used lapping discs are vitrified CBN (Cubic Boron Nitride) lapping discs and cast iron lapping discs. Understanding their differences, compositions, and advantages is essential for optimizing the lapping process for HSS workpieces.

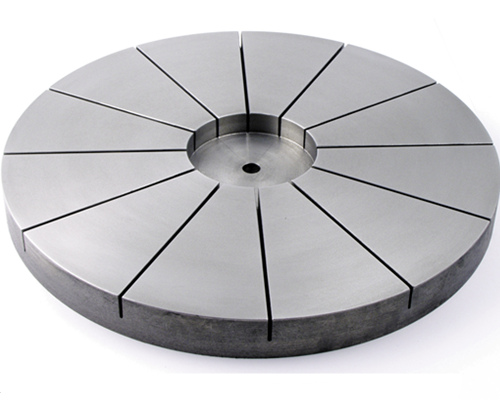

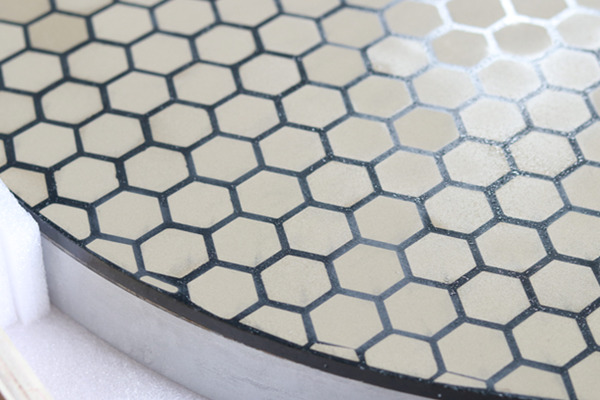

Vitrified CBN Lapping Discs for Lapping HSS Workpieces

Vitrified CBN lapping discs are engineered using Cubic Boron Nitride (CBN) abrasive grains bonded with a vitrified (ceramic) matrix. CBN is renowned for its exceptional hardness, thermal stability, and chemical inertness, making it ideal for machining ferrous materials like HSS.

Key Characteristics of Vitrified CBN lapping discs :

* High Hardness: CBN is second only to diamond in hardness, allowing it to effectively abrade hard materials such as HSS.

* Thermal Stability: CBN maintains its structural integrity at elevated temperatures, which is beneficial during high-speed lapping processes that generate heat.

* Chemical Inertness: Unlike diamond, CBN does not react with iron-based alloys, preventing chemical wear and extending tool life.

Advantages of Lapping HSS with Vitrified CBN lapping discs :

* Efficient Material Removal: The hardness of CBN facilitates rapid material removal, enhancing productivity.

* Superior Surface Finish: The fine abrasive nature of CBN yields excellent surface finishes, reducing the need for subsequent polishing.

* Extended Tool Life: The durability of CBN results in longer-lasting lapping discs, minimizing downtime for tool changes.

Cast Iron Lapping Discs

Cast iron lapping discs, traditionally used in lapping processes, are made entirely of cast iron and serve as a substrate for abrasive materials applied during lapping.

Key Characteristics of cast iron lapping disc:

-

Softness Relative to Abrasives: Cast iron is softer compared to abrasives like CBN, allowing it to embed abrasive particles on its surface.

-

Compatibility with Various Abrasives: These discs can accommodate different abrasive compounds, offering versatility in lapping various materials.

Advantages in Lapping:

* Cost-Effectiveness: Cast iron discs are generally more affordable than specialized vitrified CBN discs.

* Versatility: Their ability to work with various abrasives makes them suitable for a wide range of materials and applications.

* Comparative Analysis: Advantages of Vitrified CBN Lapping Discs Over Cast Iron Lapping Discs for Lapping HSS Workpieces.

Material Compatibility:

* Vitrified CBN Discs: Specifically designed for hard ferrous materials like HSS, offering optimal performance without chemical degradation.

* Cast Iron Discs: While versatile, they rely on the type of abrasive applied. When using conventional abrasives, they may not match the efficiency of CBN for HSS.

Lapping Efficiency:

* Vitrified CBN Discs: The inherent hardness of CBN allows for higher material removal rates, reducing cycle times.

* Cast Iron Discs: Dependent on the abrasive used; conventional abrasives may result in slower material removal on HSS.

Surface Finish Quality:

* Vitrified CBN Discs: Provide superior surface finishes due to the fine cutting action of CBN grains.

* Cast Iron Discs: Achieving similar finishes may require additional processing steps.

4. Thermal Management:

* Vitrified CBN Discs: Excellent thermal conductivity of CBN helps dissipate heat, minimizing thermal damage to the workpiece.

* Cast Iron Discs: May retain more heat, increasing the risk of thermal distortion in HSS workpieces.

5. Tool Longevity and Maintenance:

Vitrified CBN Discs: Exhibit prolonged service life with minimal maintenance due to wear resistance.

Cast Iron Discs: Require regular conditioning to maintain flatness and effectiveness, leading to increased downtime.

6. Process Consistency:

-

-

Vitrified CBN Discs: Offer consistent performance over time, ensuring uniform quality across multiple workpieces.

-

Cast Iron Discs: Performance can vary based on abrasive application and disc condition, affecting consistency.

-

7. Operational Costs:

-

-

Vitrified CBN Discs: Higher initial investment offset by reduced maintenance, longer lifespan, and increased productivity.

-

Cast Iron Discs: Lower upfront cost but may incur higher operational costs due to frequent maintenance and shorter lifespan.

-

8. Environmental Considerations:

* Vitrified CBN Discs: Produce less waste and require fewer abrasive consumables, aligning with sustainable manufacturing practices.

* Cast Iron Discs: Continuous application of abrasive compounds can lead to higher consumable usage and waste generation.

Recently we have one customer who inquiry about lapping HSS workpiece, which are widely used in cutting tools and mold manufacturing. He used cast iron lapping disc before.Traditional processing uses cast iron discs, but there are problems such as low efficiency, unstable surface quality and fast tool wear. Lets see Moresuperhard solutions together:

| Problems | Low processing efficiency: | The grinding speed of cast iron disc is slow, which affects production efficiency. |

| Unstable surface quality: | Cast iron discs can easily cause rough surface or burns on parts. | |

| Fast tool wear: | High-speed steel has high hardness, cast iron discs wear quickly, and need to be replaced frequently. | |

| Moresuperhard solutions | Choose the right grinding disc: | Choose a medium-grained ceramic CBN grinding disc, which is suitable for efficient and precise machining of high-speed steel. |

| Optimize machining parameters:

|

Adjust the grinding machine speed, feed rate and pressure to ensure high efficiency without damaging the material. | |

| Enhance cooling and lubrication: | Use special coolant to prevent overheating and improve surface quality. |

| Workpiece material | HSS |

| Size of vitrified CBN lapping disc | 920-350-45 |

| Grit of CBN lapping disc |

Conclusion

When lapping HSS workpieces, vitrified CBN lapping discs offer significant advantages over traditional cast iron lapping discs. Their compatibility with hard ferrous materials, efficient material removal, superior surface finish, and extended tool life make them a superior choice for precision lapping applications. While cast iron lapping discs provide versatility and cost-effectiveness for general applications, the specialized nature of vitrified CBN discs ensures optimal performance and economic benefits in the context of HSS lapping. Investing in vitrified CBN lapping technology aligns with modern manufacturing demands for precision, efficiency, and sustainability.

—EDITOR: Doris Hu

—POST:Doris Hu