Case of CBN Belts for polishing Turbine Blades

The turbine blades are used to boost engine power in the automotive industry. Surface roughness is an important factor for the degradation of blade performance.

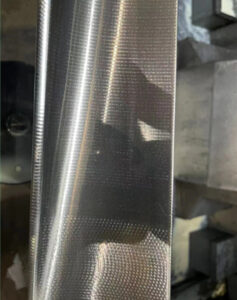

CBN sanding belts are mainly used for grinding and polishing iron-based alloys, titanium alloys, stainless steels, high-temperature alloys(Nickel-based & Cobalt-based alloys), etc.

With the increasing power of energy and power plant, in order to obtain better aerodynamic effect and maximize the power per unit volume, the blade shape develops in the direction of more curved, twisted, swept and more complex surface. In addition to the special requirements for superalloy materials, the performance of aero-engine largely depends on blade quality, which directly affects the safety and reliability of engine. The curved surface of aero-engine blade shape is more complex, more strict in size and more sophisticated in surface quality.

At the moment the aero-engine starts, the turbine blade performance degradation begins! The intense friction between the spinning turbine blades and the air can generate hundreds of degrees of heat. The rough particles on the surface of the blade will be further eroded by friction and collision, rapidly expanding the original surface defects. At the same time, the clearance between the tip of the blade, the casing, and the hub will also be further increased under the triple factors of friction, corrosion and thermal fatigue.

Therefore, high-quality turbine blades have high requirements for surface roughness. The lower the roughness, the less the “vulnerability” factor during intense friction, collision and erosion, and the longer the period of degradation. But the roughness level is only one of the criteria, roughness uniformity is also very important. The complex curvature changes of blades bring great difficulty to blade polishing.

Polishing is the last process of aero engine blade forming. Due to a variety of shapes, leaf blade after the numerical control machine tool processing, but also for high precision polishing, and three coordinates measuring instrument for waviness and surface of the blade twist testing, such as the index to accurate to u (1 u = 0.001 mm) below the accuracy of the common polishing grinding equipment can not meet such high polishing accuracy requirement!

| Belt material | CBN |

| Belts size | 3400*50 |

| Belts grit | 60# for rough and 120# for fine |

| Workpiece | Turbine Blades |

| Material | Inconel 718 |

| Grinding allowance | 1-1.5mm |

| Coolant | Oil |

| Machine speed | 1000-1500 |

| Grinding step | Rough: 1.2mm |

| Fine grinding: 0.2-0.3mm. |

–EDITOR: Alan Wang/Doris Hu

—POST: Doris Hu