Good Feedback of CNC Grinding Wheel

Recently, one of our customers from India is a middleman, but it is understood that the customer is used to process carbide tools and uses a 5-axis CNC grinding machine.

The following are the sizes required by customers after finishing:

Moresuperhard special grinding wheels for high-precision CNC grinding machines are used in single-axis or multi-axis linkage CNC grinding machines. They have the characteristics of high speed, high precision, high grinding efficiency and good retention.

| Type | Size |

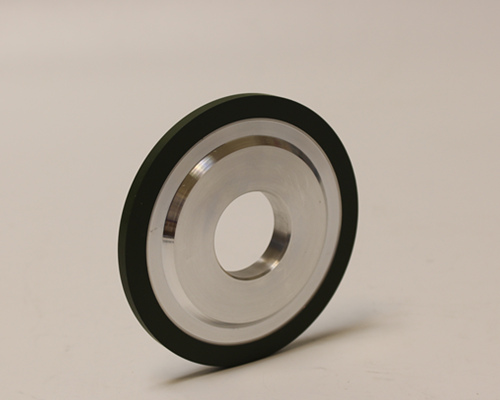

| 11V9 hybrid bond grinding wheel | 100*10*3 D64 RM6 H20 |

| 1V1 hybrid bond grinding wheel | 100*8*10 V45 RM5 D64 H20 |

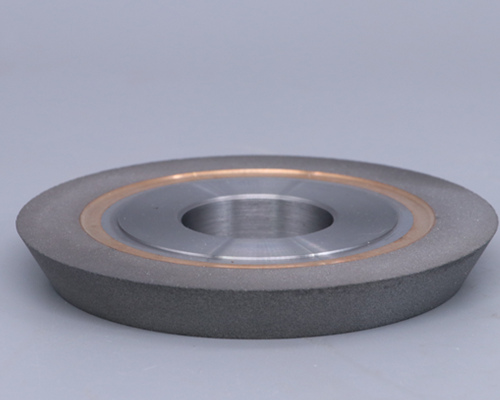

| 1A1 hybrid bond grinding wheel | 125*8*10 D64 TG10 H20 |

| 1A1 hybrid bond grinding wheel | 125*12*20*10 12-10 |

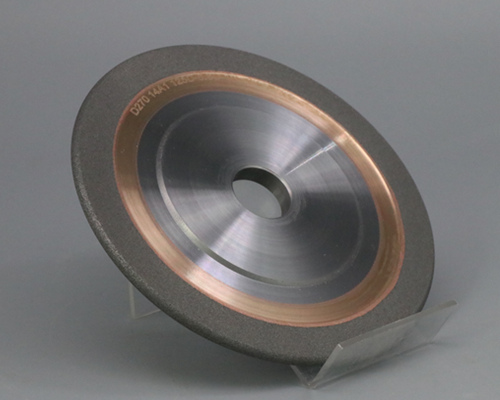

| 1A1 resin bond grinding wheel(cylindrical grinding) | 300*12*127 D64 C75 BW5 |

Resin diamond grinding wheel has high hardness, high strength, and strong grinding ability. It is mainly used for grinding high and hard alloys, non-metallic materials, cutting hard and brittle cemented carbide, non-metallic minerals, etc. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, etc.

Features of resin diamond grinding wheel:

* Diamond resin grinding wheel has good polishing effect, the grinding wheel is sharp and not easy to clog when grinding,

* High grinding efficiency, while grinding wheel consumption is relatively slow

* Good self-sharpening, low heat generation during grinding, not easy to clog, and reduces the phenomenon of work burns during grinding

* The grinding wheel has a certain degree of elasticity, which is conducive to improving the roughness of the workpiece surface. It is mainly used for fine grinding, semi-finish grinding, knife grinding, polishing and other processes.

Hybrid bonded grinding wheels are mainly used in superhard alloy tools, bearings, molds; precision ceramics; polycrystalline diamond and boron nitride; stone materials; magnetic materials; semiconductors; jewelry; aviation; automobiles; printing paper products and other industries.

Most hybrid bond grinding wheels are suitable for use with carbide (tungsten carbide) milling cutters, drills and other tools to effectively grind grooves. Then the customer mentioned two brands of grinding wheels and one brand of cutting tools.

Hybrid diamond/CBN grinding wheel has the following properties:

- High stability.

- Good cutting force. Use specially formulated metal bond to ensure good cutting force and high efficiency.

- Good shape retention. The special formula ensures that the sharp corners are not easy to wear.

- Good self-sensitivity. In the case of ensuring cutting force, good self-sharpening can maintain stable cutting force.