Good feedback of metal bond diamond honing stick for sleeves

How does a car run?

The power of a car comes from its “heart”, that is, the engine. The core of the engine is the cylinder. No matter how high the speed a car can reach, how steep the slope can be, or how heavy the cargo can be, all the power comes from inside the cylinder. The fuel is burned inside the cylinder to drive the piston to move, and then the power is transmitted to the wheels through the connecting rod, crankshaft, transmission, drive shaft, differential, and half shaft, thereby driving the car forward.

Under the same power, the more cylinders there are, the smaller the cylinder diameter can be, the higher the speed can be, and the better the running balance of the engine. However, as the number of cylinders increases, the number of engine parts also increases proportionally, making the engine structure more complex, the manufacturing cost increases, and the fuel consumption increases. Therefore, the number of cylinders in a car engine is a choice made after weighing the pros and cons based on the positioning of the vehicle model, the purpose of the engine and the performance requirements.

In a reciprocating piston engine, a car engine is generally composed of multiple cylindrical cylinders, each of which can work independently. Their power converges together to drive the car forward. These cylinders produce different forms of engines in different combinations. At present, there are three most common cylinder arrangements: in-line, V-shaped, and horizontally opposed.

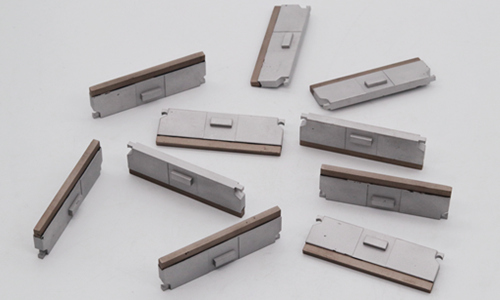

Diamond and CBN honing stick can be suitable for the processing of metal and non-metal materials. Such as cast iron, hardened and unhardened steel, hard aluminum, bronze, brass, hard chromium and carbide, glass, ceramics, crystals and sintered materials.

The cylinder liner is a cylindrical part placed in the cylinder block hole of the engine body and is fixed by the cylinder head. The piston reciprocates in its inner hole, and there is cooling water outside to cool it.

The cylinder liner is an important component in the automobile engine, and its role cannot be ignored.

First, it forms the cylinder working space together with the cylinder head and the piston to ensure the normal operation of the engine. Secondly, for the cylindrical piston diesel engine, the cylinder liner bears the side thrust of the piston. It becomes the guide of the reciprocating motion of the piston to ensure the stable movement of the piston. In addition, the cylinder liner can also transfer the heat of the piston assembly and itself to the cooling water, so that the working temperature is appropriate and the efficiency of the engine is improved. Finally, in the two-stroke diesel engine, the cylinder liner is arranged with a gas port, which is opened and closed by the piston to realize the gas distribution, so that the fuel is fully burned and the power performance of the engine is improved.

The role of the cylinder liner is not limited to this, it also plays the role of sealing and supporting. Since the engine will produce high-temperature and high-pressure gas when working, the cylinder liner can effectively seal the cylinder, prevent gas leakage, and ensure the normal operation of the engine. In addition, the cylinder liner can also support the piston assembly to keep it in the correct position and prevent the piston from falling off or being damaged due to vibration. Therefore, the cylinder liner is one of the key components for the normal operation of the engine, and its quality and performance directly affect the life and efficiency of the engine. When selecting a cylinder liner, it is necessary to consider factors such as its material, size, and processing accuracy to ensure that it can withstand the working pressure and temperature of the engine while ensuring its sealing and wear resistance. In short, the role of the cylinder liner is very important and plays a vital role in the normal operation and performance of the automobile engine.

Honing process The purpose of honing is to improve the accuracy of the cylinder liner size and improve the surface roughness, achieve precise matching between the cylinder and the piston, and form a reticulated pattern on the surface of the cylinder wall to improve the lubrication conditions of the cylinder wall.

The honing process is a special form of grinding and an efficient finishing process. The most typical application of platform honing is honing the cylinder bore of the engine cylinder block. After platform honing, a special structure can be formed on the surface of the cylinder bore (or cylinder liner), which consists of deep grooves with an oil storage function and tiny supporting platform surfaces between the deep grooves.

Honing is a special form of grinding and an efficient finishing method. This process can not only remove large machining allowances but also effectively processes parts to improve their dimensional accuracy, geometric shape accuracy, and surface roughness. It is widely used in the manufacture of engine parts.

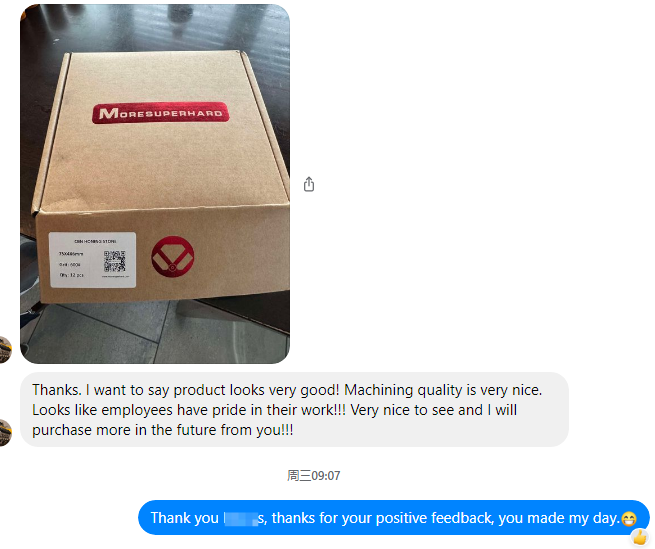

Recently, Moresuperhard received good comments from customers who purchased honing bars for honing sleeves. Let’s take a look at the feedback:

| Honing stick bond | Metal bond |

| Material | CBN |

| Grit size | 600# |

| Application | For sleeves honing |

| Machine brand | Sunnen |

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu