Good feedback of Moresuperhard vacuum brazed diamond tools

What is vacuum brazed diamond tools?

Vacuum brazed diamond tools are diamond tools made by connecting diamond to the matrix by brazing. The diamond and the matrix have high bonding strength and are not easy to fall off. At the same time, they have the advantages of large abrasive grain exposure height (theoretically more than 70% of the abrasive grain height), large chip space, good heat dissipation, etc. They can withstand large loads during use and can be used for high-speed and efficient grinding. Vacuum Brazed diamond tools are suitable for grinding, cutting cast iron, and processing stone, ceramics, glass, and reinforced concrete.

The principle of vacuum brazed diamond tools is to use elements with high affinity to C elements (such as Ti, Cr, Zr, etc.) to produce carbides during brazing, thereby realizing the metallurgical bonding between diamond, brazing material and matrix. For the brazing of diamond tools, brazing process and brazing materials are the most important influencing factors.

Compared with electroplated diamond tools, vacuum brazed diamond tools have high bonding strength, strong diamond holding force, large chip space, low power consumption, low cutting force, high processing efficiency, long service life, high utilization rate of diamond, and can achieve the advantages of optimized arrangement of diamond abrasives. More importantly, the production process is pollution-free and adapts to today’s green production concept.

Brazing process of diamond tools

The brazing processes that can be used for diamond tools at present include: vacuum brazing, furnace brazing, salt bath brazing, flame brazing, laser brazing, resistance brazing, high frequency and vacuum induction brazing, etc. The bonding strength determines the performance and service life of diamond tools. In order to prevent the oxidation of the brazing material, diamond tools are often brazed in high vacuum or under inert gas protection.

Vacuum brazing

The vacuum and gas shielded welding environment requires a specific furnace to provide; furnace brazing generally uses resistance radiation heating, which is evenly heated and can weld diamond tools with complex structures and large sizes. Vacuum brazed single-layer diamond tools are mainly used in the manufacture of dressing tools, grinding wheels, stone tools, and glass tools. Vacuum brazing and furnace brazing are both suitable for mass production. Continuous atmosphere protection furnace brazing uses ammonia decomposition gas as a reducing gas, with slow heating speed and uniform temperature. The brazed joints are beautiful, reliable in quality, bright on the workpiece surface, high in production efficiency, and low in welding cost. It is often used in the production of small saw blades and special-shaped diamond tools. Salt bath brazing has a low temperature, fast and uniform heating speed, and low graphitization degree of diamond, which is suitable for mass production.

Salt bath brazing

However, the salt bath brazing process is cumbersome, the workpiece brazing flux residue is serious after welding, and a large amount of wastewater is generated during cleaning to pollute the environment. In addition, the equipment for salt bath brazing is expensive and the production cycle is long. Salt bath brazing of diamond tools is contrary to the development concept of green manufacturing.

Flame brazing

Flame brazing is a very early developed brazing method. The required equipment is simple and light, the gas source is wide, and the process cost is low, but its heating temperature is not easy to control and has gradually been eliminated by the mainstream market.

Laser brazing

During laser brazing, the laser heating is heated quickly locally, the diamond is exposed to high temperature for a short time, and the graphitization degree of diamond is low. Laser brazing has high heating efficiency, easy temperature control, small heat-affected zone, can process complex curved surfaces, and can also realize the orderly arrangement of diamond particles. It has a high degree of automation and a good working environment. Laser brazing is used to weld large-sized and special-shaped complex workpieces, and can also avoid the proximity effect and skin effect of high-frequency induction brazing. However, due to the short heating time, it is impossible to ensure the formation of a continuous reaction layer or diffusion layer between the diamond abrasive and the brazing material, and between the brazing material and the matrix, thereby reducing the holding force of the brazing material on the diamond particles.

Resistance brazing is commonly used for brazing of honing rods, and its weld quality is good; but since the overall temperature of the cutter head is at a high temperature during the welding process, it affects the service life of the diamond. Currently, only a few companies use this process.

High-frequency brazing

High-frequency induction brazing has fast heating speed, high brazing efficiency, low production cost, simple operation, low labor intensity, and can braze various complex shapes and multi-tooth workpieces. When automatic feeding, atmosphere protection or vacuum induction brazing is used, the joint has good appearance and brazing quality. Induction brazing is a brazing method for manufacturing diamond tools with good development prospects.

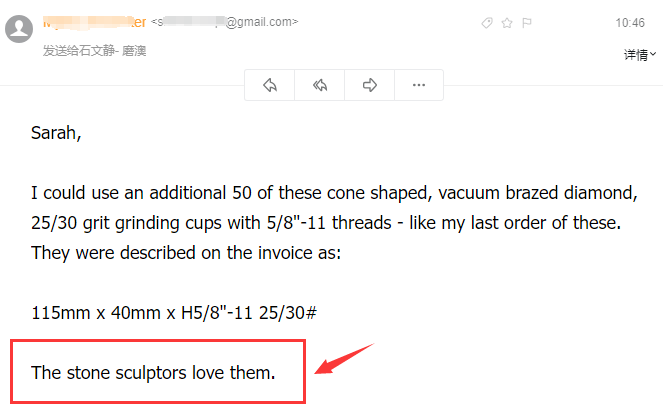

Recently Moresuperhard received the good news from our customers who ordered vacuum brazed diamond tools, lets see it together:

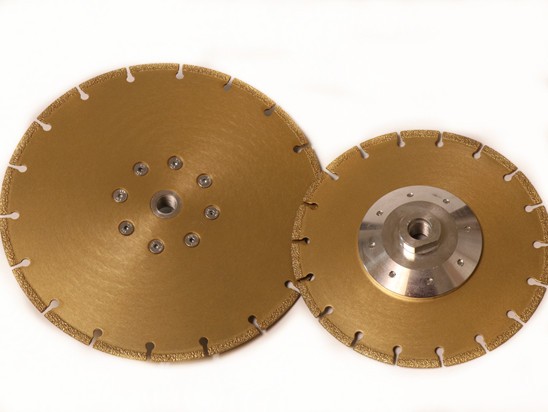

Product paraments:

Good Feedback from customer:

Moresuperhard can provide vacuum brazed diamond grinding wheel/grinding pins/cutting disc/grinding discs/drill bit…

Diamond vacuum brazed tool is ideal for grinding cast iron, marble, ceramic materials, fiber-reinforced plastic , silicon carbide, and artificial stone.

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu