Good feedback of resin and vitrified diamond grinding wheel for HVOF coating

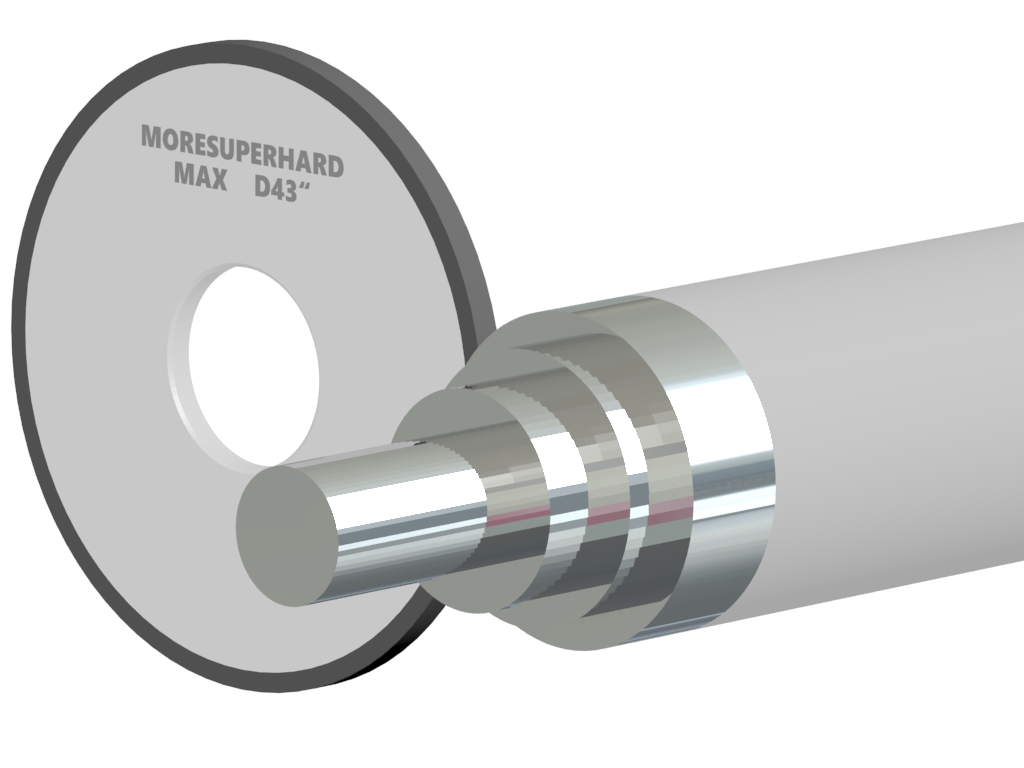

The production of high-quality rolled plates cannot be separated from high-quality grinding of rolls. As an important component in steel rolling production, the quality of rolls directly affects the quality of rolled products and production efficiency. Roller grinding is a key process in the manufacturing and repair of rolls. The quality of grinding directly affects the service life of the rolls, rolling performance and product quality. Roller grinding utilizes the relative movement between the grinding wheel and the roll to remove the fatigue layer on the roll surface through the grinding action of the grinding wheel, restore the mechanical and physical properties of the surface, and achieve the required roll shape accuracy and surface roughness.

Roller grinding has the following characteristics: (1) High grinding accuracy requirements: The dimensional accuracy and surface roughness requirements of the rolls are usually very strict to ensure the quality of the rolled products. (2) Large grinding allowance: Since the rolls will be worn and damaged during use, more metal needs to be removed to restore their shape and size. (3) Large grinding force: The hardness of the rolls is relatively high, and a large grinding force is required during grinding, which places high demands on grinding equipment and processes.

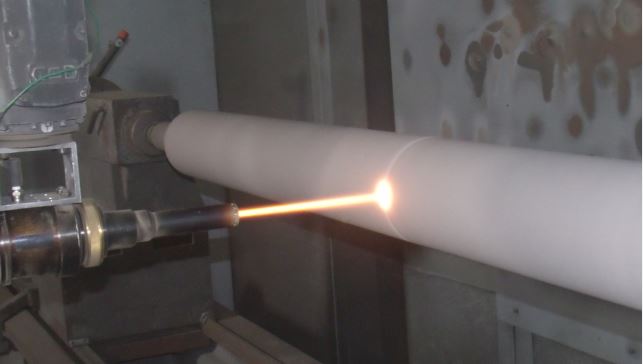

What is HVOF spraying?

High velocity oxygen fuel (HVOF) spraying is a group of thermal spray processes that eject a flame at supersonic speeds.

In HVOF processes, the kinetic energy of the particles is more important than temperature. These processes use high impact energy to produce dense coatings at lower temperatures.

In HVOF spraying, fuel and oxygen are continuously pressed into a combustion chamber to produce a jet of combustion products at very high velocities. Powder particles injected into the gas vapor are accelerated to very high velocities. Fusion is achieved by kinetic impact of the coating particles rather than by temperature increase: the process is carried out in ambient air.

Advantages of HVOF coating:

Ideal for coating large components

A relatively cool coating process is required due to the short-lived existence of the particles in the hot gas stream

High density carbides can be produced without degradation due to high temperature effects.

HVOF is widely used to produce high quality wear resistant coatings of carbides and Stellites. It is also used to apply MCrAlY coatings, which are alloys of M (metal = nickel, cobalt or iron, or a combination thereof), Cr (chromium), Al (aluminum), and Y (yttrium). The finishing of thermal spray coatings usually adopts grinding method because it can achieve higher precision and better surface roughness. For the grinding of thermal spray coatings, resin and vitrified diamond grinding wheels are mostly used.

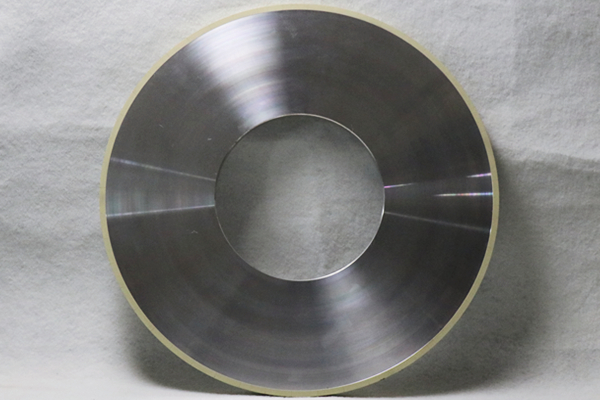

Resin diamond grinding wheels are designed for fast and cool cutting;perform well in both wet and dry grinding application. resin bond diamond grinding wheel for grinding and finishing of thermal spray coatings ( including tungsten carbide , chrome carbide and chrome oxide ), ceramics, carbides, chilled iron composites and other hard-to-grind materials.

vitrfied bond diamond grinding wheel

* For hard surface grinding tungsten carbide workpieces

* Steel based tungsten carbide coating workpiece

* Non-metallic materials semi-finishing grinding and finishing grinding, etc.

Features of diamond grinding wheels for thermal spray

* The bonding strength of vitrified bond to grinding is better than resin bond

* After customized diamond grinding tools with higher diamond concentration, it is less heat and jam generate in grinding

* High grinding efficiency

* Very sharp grinding

* Long lifespan and easy to dress

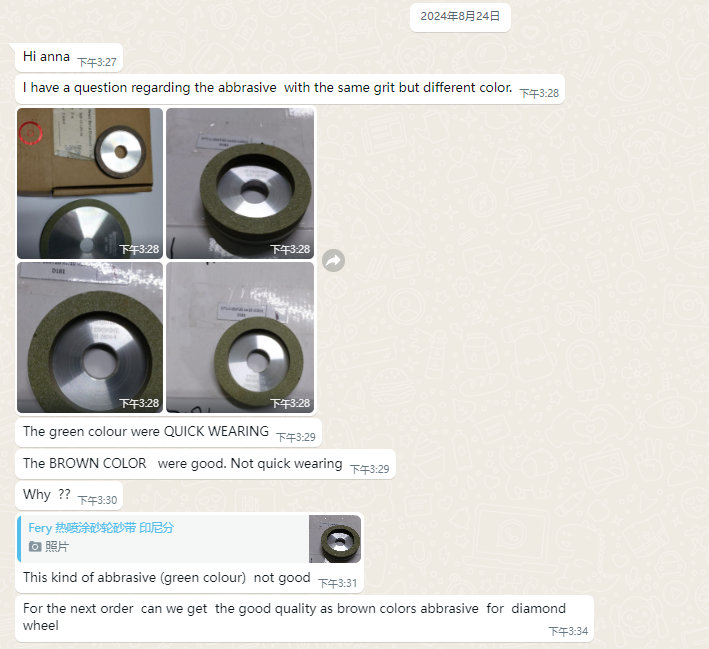

Recently, Moresuperhard receive the good feedback from our customers, lets see it together:

| Vitrified bond diamond grinding wheel | D75-H20-T20-W10-X10, D181 |

| Resin bond diamond grinding wheel | D50-H12-T6-5X |

| Roll size | OD1500 x L3100mm |

| Grit of Moresuperhard diamond grinding wheel | D151 D181 D76 |

| Workpiece | HVOF tungsten material and ceramic roll |