Metal diamond cutting blades for PCB board

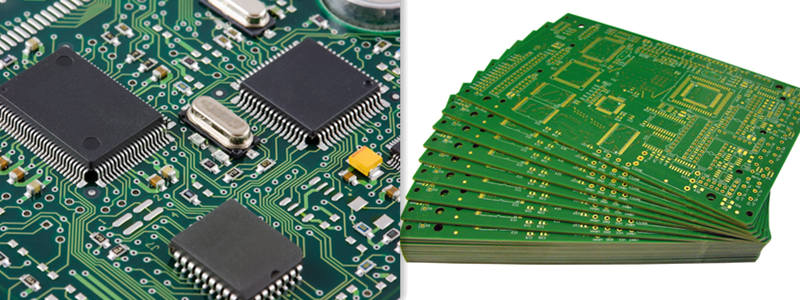

What is PCB?

PCB is the abbreviation of Printed Circuit Board. It is a substrate used to support and connect electronic components. PCB is a flat board made of insulating material on which electronic components are laid out and connected through structures such as conductive tracks, holes and pads. It is one of the most common components in electronic devices and is used to build and support electronic circuits. Metal diamond cutting blade is mainly used for cutting kinds of composite circuit board,such as copper -based,rubber-based and plastic-based circuit board.

What structure does the PCB circuit board consist of?

1. Substrate

The substrate is the main body of the PCB, usually made of insulating materials, such as fiberglass reinforced epoxy resin (FR-4). It provides mechanical strength and support structure while having good insulating properties.

2. Traces

Traces are metal tracks on the PCB, used to connect circuit paths between electronic components. They are typically made from copper foil, formed through processes such as etching or added plating. Width, spacing and layering of wires can be adjusted according to circuit design requirements.

3. Vias

Vias are through holes that connect different PCB levels. Through the holes, pins such as signal, power, and ground wires can be led out from one layer of wires and connected to wires on other levels to realize the connection of multi-layer circuits.

4. Pads

Pads are metal areas used to connect the pins of electronic components. They are usually located on the PCB and are used to solder components to ensure reliable electrical connections.

5. Components

Components are electronic components installed on PCB, such as integrated circuits, resistors, capacitors, and connectors. They are laid out on the PCB and connected to the PCB’s wires and pads by soldering or insertion.

Why need cutting PCB slicing?

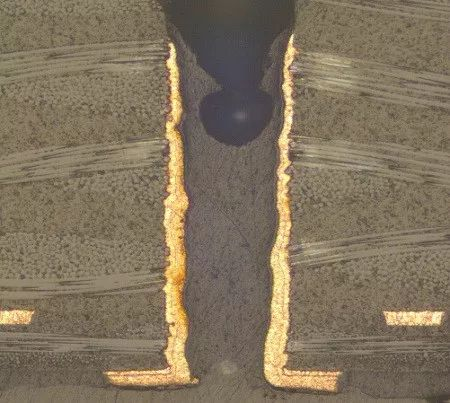

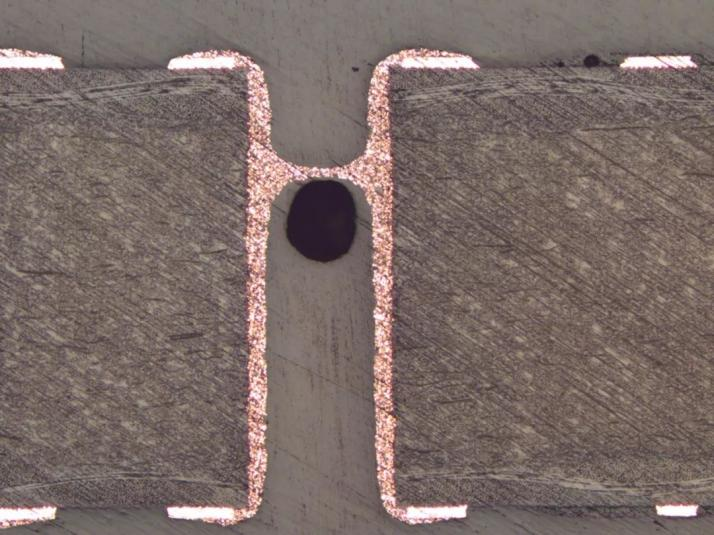

The quality of the circuit board and the evaluation of process improvement need to be sliced as the basis for objective inspection and judgment. Slice analysis with metallographic equipment is an important means to check PCB/PCBA internal line thickness, layer number, through hole aperture size, through hole quality observation, PCB/PCBA solder joint internal cavity, interface bonding status, and wetting quality evaluation.

Microscopic detail analysis of sections by metallographic microscope and scanning electron microscope, poor quality sections will lead to serious misdirection and misjudgment in failure analysis. Metallographic microscope as the most important analytical equipment, its magnification varies from 50 to 1000 times, and the measurement accuracy deviation is less than 1μm.

How to cutting PCB slicing?

General cutting method can be divided into vertical slices and horizontal slices.

1. The vertical slice is cut in the direction perpendicular to the plate surface to observe the profile condition, which is usually used to observe the quality of the hole after copper plating, the laminated structure and the condition of the internal bonding surface. Vertical slicing is the most commonly used method in slice analysis.

2. The horizontal section is ground down layer by layer along the superimposed direction of the board to observe the condition of each layer, which is usually used to assist the analysis and determination of quality anomalies in the vertical section, such as short or open anomalies.

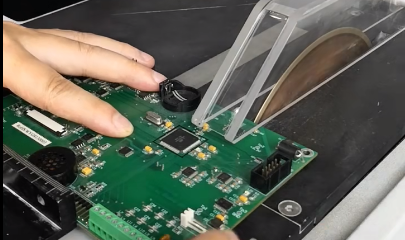

Recently Moresuperhard have one customer, who want to slicing PCB,lets see the suggestions for him:

| Bond of diamond cutting blade | Metal diamond cutting blade | |

|

Size |

Diameter | 80mm |

| Hole | 20mm | |

| Thickness | 1.3mm | |

| Diamond layer | 5mm | |

Metal diamond cut off wheels are installed into the precision metallurgical sample cutting machine/PCB cut machine for cutting PCB /SMT semiconductor. Due to metal diamond cutting blade haves the features of goods sharp,non-sticky,high precision,good surface quality and extremely high service life, so it is more ideal for PCB board slicing.

—EDITOR: Doris Hu,Anna Wang

—POST: Doris Hu