Case of metal CBN grinding wheel for gear hob cutter

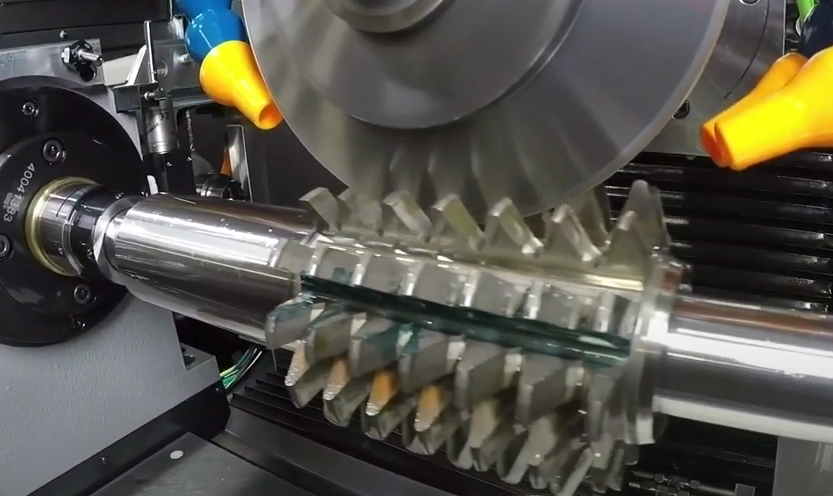

The integral gear hob has the characteristics of high precision and high single value. The hob will have unequal tooth grooves. When grinding the hob, a grinding wheel will be used to grind the tooth surface in the tooth groove. Through the indexing of the mandrel, Achieve grinding of all rake angles. Since the number of tooth grooves of each module hob is inconsistent, and the more consistent the grinding depth of all rake angles, the service life of the hob after a single grinding will be better, but if it is ground too deep, it will Reducing the number of times the hob can be regrinded will affect the overall life of the entire hob. Therefore, the selection of the single grinding allowance for the rake angle is a difficult point.

Gear hob cutters are tools that process gears according to the generation method. They are widely used in gear manufacturing and can be used to process external meshing spur gears, helical gears, standard gears and variable gears. It has a wide range of gear processing, and gears with module module 0.1~40mm can be processed with hobs.

Gear hob cutters are gear processing tools whose cutter teeth are arranged in a spiral along a cylinder or cone. They are used for processing cylindrical gears, worm gears and other cylindrical toothed workpieces. According to different uses, hobs are divided into gear hobs, worm gear hobs, non-involute hobs and fixed hobs. During the gear cutting process, the manufacturing error of the hob mainly affects the tooth shape error and base pitch deviation of the gear.

As the degree of wear of the gear hob increases during use, the cutting performance will decrease, which will increase the roughness of the machined tooth surface, increase the cutting force, and cause vibration or abnormal sounds during the cutting process. If you continue to use it at this time, it will not only further deteriorate the processing quality, but also sharply wear the tool. Therefore, when the hob itself cannot meet the process requirements, it needs to be ground.

Recently, Moresuperhard had a customer, who want sharpening gear hob cuter, let’s see the suggestions for him:

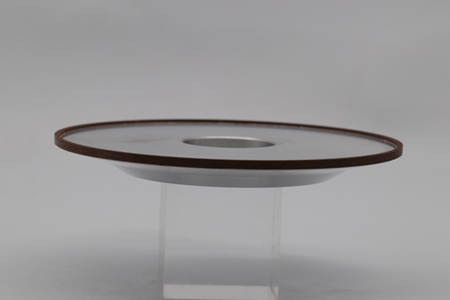

Case of metal CBN grinding wheel for sharpening gear hob cutter tooth face

| Size of metal CBN grinding wheel | 4BT9 D150xH50.8xT25xW10xX4 B91 |

| Parts for grinding | gear hob cutter tooth face |

Test feedback:

1. The grinding wheel is resistant to grinding and has one-third longer service life than its peers.

2. The grinding wheel has good self-sharpening properties, which reduces the frequency of dressing and saves time.

3. The grinding wheel has high precision and good grinding effect

4. The soft and hardness formula of the grinding wheel meets customer requirements, and there is no burn or blackening.

5. The grinding wheel consumes less and has a long service life.

—EDITOR: Doris Hu, Sarah Shi

—POST: Doris Hu