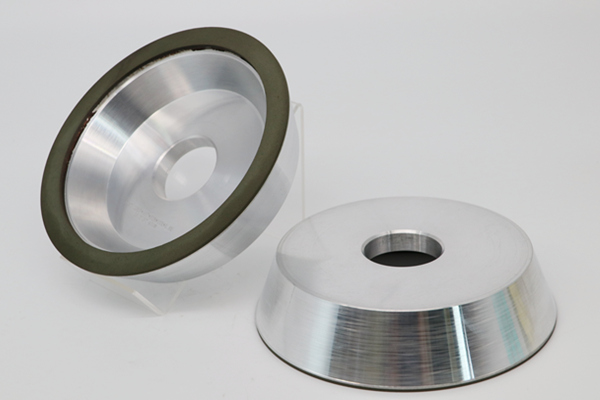

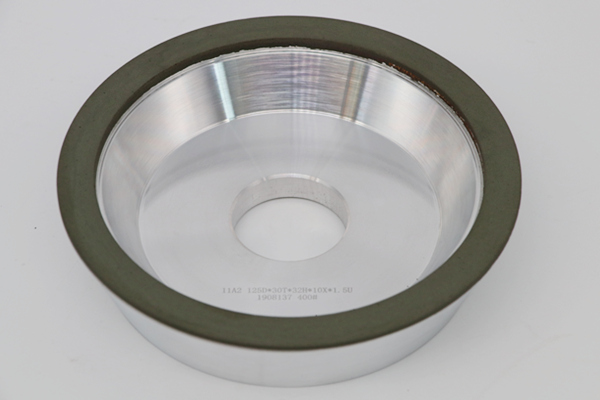

Resin Diamond Grinding Wheel for Grinding CBN Cutting Tools

In the realm of manufacturing and precision engineering, the demand for tools that can handle challenging materials with precision has catalyzed the development of advanced cutting tools. Cubic Boron Nitride (CBN) cutting tools have emerged as a vital component in machining processes due to their exceptional hardness, heat resistance, and durability. To ensure that these specialized tools maintain their precision and efficiency, the grinding process plays a crucial role. One of the key elements in this process is the utilization of resin diamond grinding wheels. As a leading manufacturer in this industry, Moresuperhard is dedicated to providing high-quality diamond and CBN grinding wheels that cater to the needs of precision tool grinding.

Description of CBN Cutting Tools

Cubic Boron Nitride (CBN)

CBN is a synthetic crystal structure created from boron and nitrogen atoms, making it one of the hardest materials known to man, second only to diamond. CBN cutting tools exhibit exceptional hardness, thermal conductivity, and wear resistance, making them ideal for machining applications involving hard and abrasive materials. These tools are particularly popular in industries such as automotive, aerospace, and tool manufacturing, where precision and efficiency are paramount. CBN cutting tools are widely used in operations such as turning, milling, and grinding, where the machining of hardened steels, cast irons, and superalloys is required.

Types of CBN Cutting Tools

CBN cutting tools come in various forms to cater to different machining requirements. Some common types of CBN tools include inserts, end mills, drills, and grinding wheels. These tools are designed with specific geometries and cutting edges to enable efficient material removal and surface finishing. The composition and structure of CBN cutting tools are engineered to withstand high temperatures and wear, ensuring consistent performance and longevity in demanding machining environments.

How to Grind CBN Cutting Tools

Grinding CBN cutting tools is a meticulous process that requires precision, expertise, and specialized equipment. The grinding of CBN tools is essential to maintain their sharpness, geometries, and cutting performance. Here are the key steps involved in grinding CBN cutting tools:

Selection of Grinding Wheel:

Choosing the right grinding wheel is critical in the grinding process. Resin diamond grinding wheels are preferred for grinding CBN cutting tools due to their excellent cutting ability, durability, and precision.

Wheel Dressing:

Before initiating the grinding process, it is essential to dress the resin diamond grinding wheel to ensure its optimal condition. Dressing removes any impurities, irregularities, or worn-out particles from the wheel’s surface, thereby enhancing its cutting efficiency and prolonging its lifespan.

Setting Grinding Parameters:

The grinding parameters, including the wheel speed, feed rate, and depth of cut, need to be meticulously set to match the specific requirements of the CBN cutting tool being ground. These parameters are crucial in achieving the desired surface finish, sharpness, and dimensional accuracy of the tool.

Coolant Application:

In the grinding process, the application of a suitable coolant is essential to dissipate the heat generated during the grinding operation. As CBN cutting tools are known for their exceptional heat resistance, the use of coolant helps prevent thermal damage to the tool and ensures the maintenance of its structural integrity.

Precision Grinding:

The grinding of CBN cutting tools demands a high degree of precision to achieve the desired cutting edge profiles and surface finishes. The interaction between the resin diamond grinding wheel and the CBN tool must be carefully controlled to avoid any undesirable effects such as burning, surface cracks, or tool edge chipping.

Inspection and Quality Assurance:

Once the grinding process is completed, rigorous inspection and quality checks are carried out to ensure that the ground CBN cutting tools meet the specified dimensional tolerances, surface roughness requirements, and cutting edge integrity. Any deviations or defects are addressed to guarantee the tool’s functionality and performance.

Final Polishing and Finishing:

Depending on the application and precision requirements, a final polishing or finishing operation may be conducted to further enhance the surface quality and cutting performance of the CBN cutting tool. This step ensures that the tool is impeccably prepared for its intended machining tasks.

Advantages of Grinding CBN Cutting Tools with Resin Diamond Grinding Wheel

High Material Removal Rate:

Resin diamond grinding wheels are renowned for their superior material removal capabilities, making them highly efficient in the grinding of CBN cutting tools. The sharp, durable diamond abrasives embedded in the resin bond enable rapid stock removal, thereby expediting the grinding process and enhancing productivity in tool manufacturing operations.

Minimal Tool Wear:

The precise nature of resin diamond grinding wheels ensures that the CBN cutting tools undergo minimal wear during the grinding process. This results in extended tool life, reduced tool maintenance requirements, and cost savings for manufacturers in terms of tool replacement and downtime.

Enhanced Surface Finish

Resin diamond grinding wheels contribute to achieving a superior surface finish on CBN cutting tools, characterized by smoothness, accuracy, and minimal surface defects. The precise cutting action of the diamond abrasives in the resin bond allows for the generation of fine finishes on the tool surfaces, promoting optimal performance and quality in machining operations.

Dimensional Accuracy

Grinding CBN cutting tools with resin diamond grinding wheels facilitates the attainment of precise dimensional accuracy in the tool profiles and cutting edges. The consistent grinding action of the diamond abrasives ensures the maintenance of tight tolerances and geometrical integrity, enabling the CBN tools to meet exacting specifications and requirements for machining operations.

Heat Dissipation

Resin diamond grinding wheels are effective in dissipating heat during the grinding process, which is essential for preserving the structural integrity and performance characteristics of CBN cutting tools. The efficient heat dissipation capability of these grinding wheels helps prevent thermal damage to the tools, ensuring that they remain stable and durable throughout their operational lifespan.

Versatility and Adaptability

Resin diamond grinding wheels offer versatility and adaptability in grinding various CBN cutting tools, irrespective of their geometries, materials, or complexities. The wide range of resin bond formulations and diamond abrasive configurations available enables manufacturers to customize the grinding process according to specific tool requirements, thereby enhancing flexibility and precision in tool manufacturing processes.

Recently Moresuperhard received a customer inquiry about grinding wheels for CBN tools, let’s see the solutions together:

| Workpiece | CBN cutting tools |

| Size of resin diamond grinding wheel | 11A2 D125*H32*T32*W10*X10 600# |

| Grinding method | Dry grinding |

In conclusion, the utilization of resin diamond grinding wheels for grinding CBN cutting tools is instrumental in ensuring the optimal performance, longevity, and quality of these precision tools. By harnessing the advanced capabilities of resin bond technology and diamond abrasives, manufacturers can achieve remarkable results in terms of material removal efficiency, tool wear reduction, surface finish enhancement, dimensional accuracy, heat dissipation, and process versatility. Moresuperhard, as a distinguished diamond and CBN grinding wheel manufacturer, continues to pioneer innovation in the field of tool grinding, providing cutting-edge solutions that elevate the standards of tool manufacturing and machining excellence.

With a deep understanding of the significance of CBN cutting tools, the intricacies of the grinding process, and the advantages of resin diamond grinding wheels, manufacturers can elevate their tool manufacturing capabilities, optimize machining operations, and deliver exceptional results in diverse industrial sectors.

As the industry continues to evolve and the demand for advanced cutting tools grows, precision grinding technologies and tools will remain pivotal in shaping the future of manufacturing and engineering excellence.

—EDITOR: Doris Hu, Cindy Chen

—POST: Doris Hu