Honing

What’s the Honing?

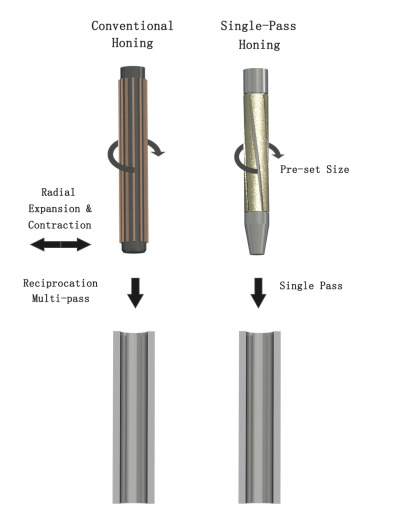

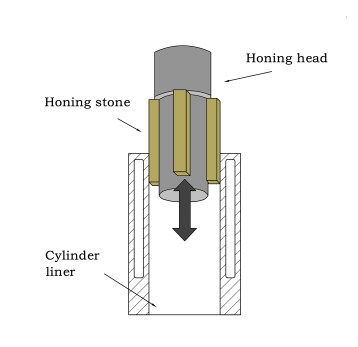

Honing is to use several whetstones installed on the circumference of the

Honing is mainly used for the machining of precision holes, such as engine cylinder holes, compressor cylinder holes, connecting rods, pump bodies and control blocks.

The honing tool is commonly known as the honing head. Several whetstones are installed on the circumference of the honing head, generally 4-6. Because the expanding mechanism expands the whetstone in the radial direction, a certain pressure is generated on the hole wall of the workpiece, and the honing head rotates. Movement and reciprocating linear motion, low-speed grinding and friction polishing of inner holes.

Honing can achieve the following technical indicators:

Honing inner hole size: 1 ~ 1200mm;

Honing inner hole depth: 1 ~ 20 000mm;

Dimensional accuracy: 0.002 ~ 0.01mm;

Honing technology can not only be used in the manufacture of automobiles, motorcycles, tractor cylinders, crankshafts, but also widely used in aircraft, missiles, tanks, combat vehicles, artillery, ships, industrial sewing machines, air-conditioning refrigerators, hydropneumatics, radar, broadcasting TV equipment, machine tools, molds, brakes, oil pump nozzles, bearings, construction machinery, wind instruments and other manufacturing fields.

(1) It is widely used in smoothing or finishing of holes of various shapes, with a diameter of 1 to 1200mm and a length of up to 12000mm. The working range of domestic honing machine: full 5 ~ 250mm, hole length 3000mm.

(2) It can be used for the processing of outer circle, spherical surface and inner and outer annular surfaces. Such as chrome-plated piston rings, tappet spherical surfaces and inner and outer rings of ball bearings, etc.

(3) It is used for mass production in automobile, tractor and bearing manufacturing, and is also suitable for mass production in various machinery manufacturing. Such as honing cylinder liners, cylinder holes, connecting rod holes, oil pump nozzles and hydraulic valve body holes, shaft sleeves, rocker arms and gear holes, etc.

(4) It is suitable for the processing of metal materials and non-metal materials. Such as cast iron, hardened and unhardened steel, hard aluminum, bronze, brass, hard chrome and carbide, glass, ceramics, crystal and sintered materials.