Surface Finishing, Double Disc Grinding Wheel

Application: carbide, tungsten steel, ceramic , optical glass, sapphire glass, high speed steel, bearing steel, tool steel, stainless steel and cast iron, etc

Bond: vitrified bond & resin bond

Diameter: 300- 1500mm

Advantages: Reduced cutting forces, Increased removal rates, Increased precision, Reduced disposal costs, Reduced machine downtime

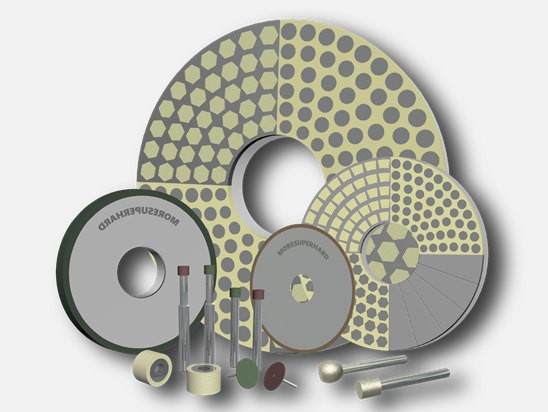

Diamond & cbn shapes: cylindrical, hexagonal, square, segmented

Grinding machines: Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

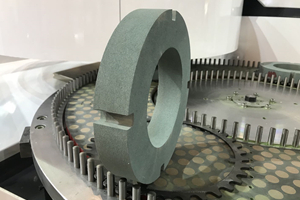

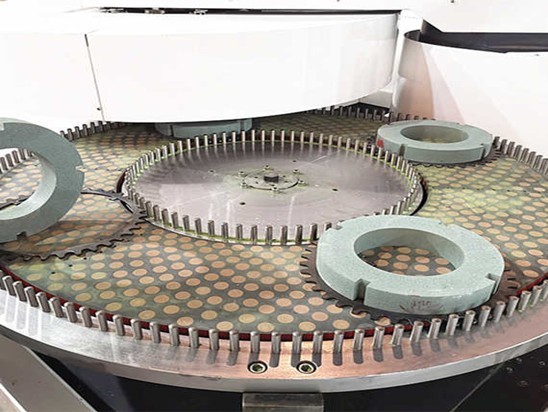

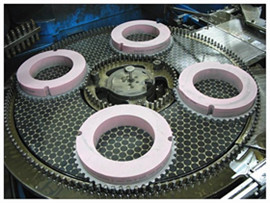

Description of Double Disc Grinding Wheel:

More SuperHard company offers a full line of diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems. Our vitrified diamond and CBN grinding discs have high grinding efficiency, high wear resistance and abrasive consumption, good surface quality and flatness of the workpiece.

Advantages of Top and Bottom Grinding Wheels:

1.High grinding efficiency,Long service life and Good shape retention.

2. High strength synthetic diamond for high removal rates while excellent finish.

3. Sharp shape synthetic diamond for long dressing intervals.

4. Free cutting design for low cutting energy.

5. Better cutting edge with smaller chipping.

6. Good uniformity of size because the stable uniform structure and materials in abrasive layer.

7. High flatness, good finish, and parallemism.

8. Save your labor costs.

Applicable Areas of double discs:

♦ Hydraulic pneumatic components. vane pump, conversion valve, piston pump,fuel pump, hydraulic motor parts

♦ Compressor spare parts. air conditioner compressor vane, piston, Refrigerator compressor valve plate, cylinder block (grey cast iron or nodular cast iron), sleeve (alloy cast iron), slide (high speed steel)

♦ Engine parts. automobile fuel pump parts, booster pump parts,oil pump nozzle parts

♦ High precision shaft ,seal, watch parts, molds, carbide blade, ceramic valve core,magnetic materials,etc

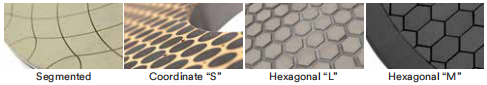

Various Layouts of double discs:

Shape of resin bond grinding segment: circular, straight segment (other shapes can be customized)

Shape of the vitrified bond grinding segment: regular hexagon, sector, square ,circular, trigonometrical, hexagonal pellets (other shapes can be customized)

Typical Grinding machine for double disc:

Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

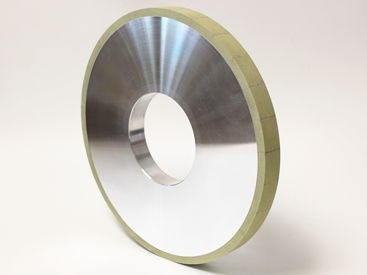

Matching dressing grinding wheel

The dressing wheels are used for dressing diamond and CBN wheels. According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving.

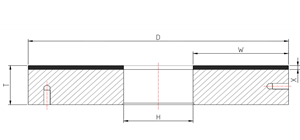

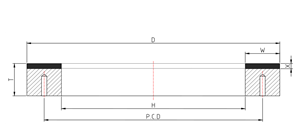

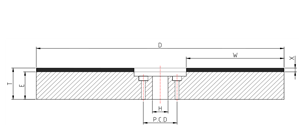

| Drawing | Specification |

1A2T

|

D: 300mm – 1500mm |

2A2T |

W(Abrasive layer width): 40mm – 350mm |

6A2B |

X( Abrasive layer height): 3mm -10mm |

| Flatness:<=2μm, parallelism:≤ 2μm Roughness: Ra0.02μm-Ra0.2μm Durability: grinding HSS slide (25mm*25mm), the number of workpiece ≥ 1million grinding carbide blade, the number of workpiece ≥1million |

|

Related Products

-

Surface Finishing, Double Disc Grinding Wheel

Surface Finishing, Double Disc Grinding Wheel

-

Vitrified Diamond cBN Double Disc Wheels

Vitrified Diamond cBN Double Disc Wheels

-

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

-

Diamond Cylindrical Wheel for Precision Ceramic Grinding

Diamond Cylindrical Wheel for Precision Ceramic Grinding

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

MoreSuperhard offers custom precision ceramic grinding, lapping and polishing service and solution.

High Precision Ceramic Grinding Lapping

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.