Surface Grinding

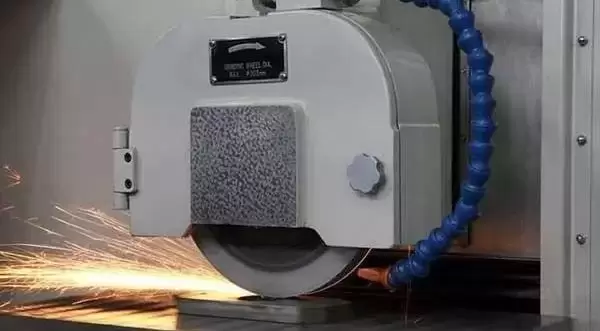

What is Surface Grinding?

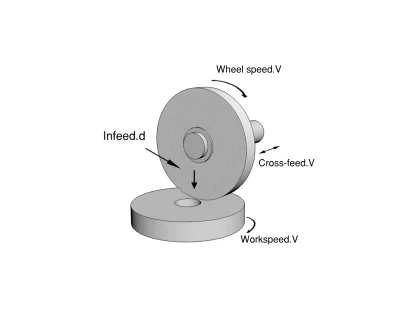

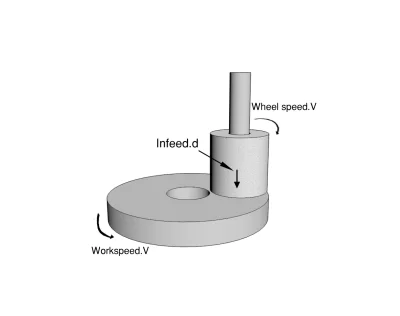

Surface grinding is used for grinding planes, grooves, etc. on surface grinders. The workpiece is rotatably ground with a grinding wheel to achieve the required flatness. According to the shape of the worktable, it can be divided into two types: rectangular worktable and circular worktable. The main parameters of the rectangular worktable surface grinder are the width and length of the worktable, and the main parameter of the circular worktable is the diameter of the worktable. According to the different types of shafts, it can be divided into horizontal shaft and vertical shaft grinders.

Surface grinding methods include

-Horizontal-spindle,

-Vertical-spindle,

-Vertical-spindle rotary grinding,

-Horizontal spindle single disk, and vertical swivel head grinding.

Form of surface grinding:

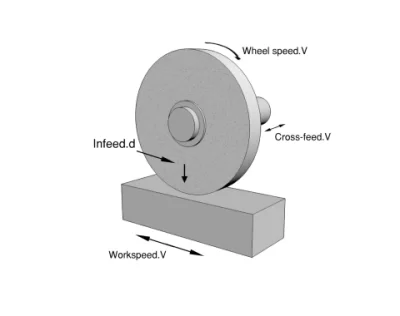

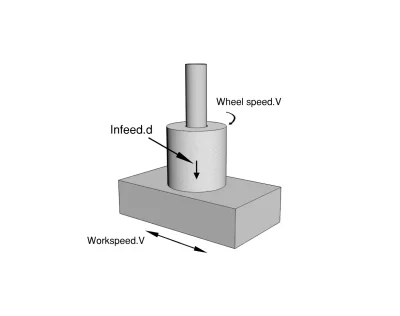

Depending on the working surface of the grinding wheel, surface grinding can be divided into three methods: peripheral grinding, end face grinding and peripheral end face grinding.

(1) Peripheral grinding: also known as circumferential grinding, is to use the circumferential surface of the grinding wheel for grinding. Surface grinders with horizontal axes fall into this category.

(2) End face grinding: Grinding with the end face of the grinding wheel. Surface grinders with vertical axes belong to this form.

(3) Grinding of one end face of the periphery: Grinding the circumferential face and end face of the grinding wheel at the same time. When grinding the step surface, if the step is not deep, you can use the grinding wheel to grind the peripheral end face on the horizontal axis and rectangular table surface grinder.

How to choose the surface grinding wheel?

– When grinding with the circumference of the grinding wheel, the parallel grinding wheel with vitrified bond is generally used, the particle size is F36~F60, and the hardness is between H~L.

– When the end face of the grinding wheel is used for grinding, due to the large contact area, the difficulty of chip removal, and the easy heat generation, most of the cylindrical or insert grinding wheels use resin bond, the particle size is F20~F36, and the hardness is between J~L.

-

Grinding segment

-

Diamond Face Grinding wheels for circular saw blades

Diamond Face Grinding wheels for circular saw blades

-

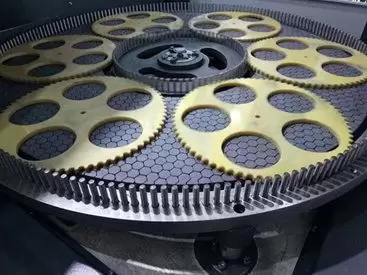

Surface Finishing, Double Disc Grinding Wheel

Surface Finishing, Double Disc Grinding Wheel

-

Resin bond Diamond Face Grinding Wheel

Resin bond Diamond Surface Grinding Wheel

-

Grinding Grooves 2 Sides Face Diamond Grinding Wheel

Grinding Grooves 2 Sides Face Diamond Grinding Wheel

-

Vitrified Diamond Surface Grinding Wheel

Diamond Surface Grinding Wheel

-

Resin Diamond Lapping Discs for Gemstone surface grinding

Resin Diamond Lapping Discs for Gemstone surface grinding