Internal Grinding

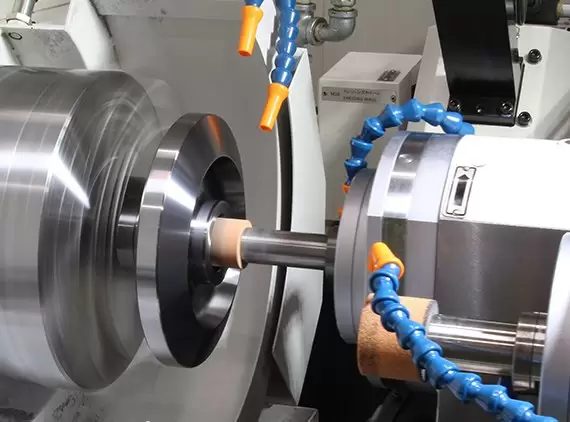

Internal grinding is used for the finishing of internal holes and is carried

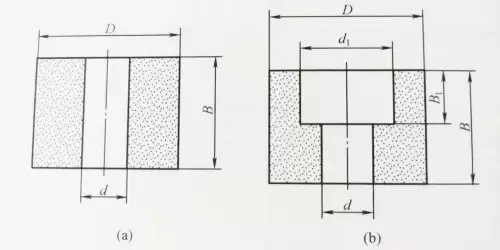

The commonly used shapes of internal grinding wheels are flat and cup (see the figure below). Among them, the flat grinding wheel is the most commonly used, and the cup-shaped grinding wheel is more advantageous for grinding stepped holes and sections.

What are the methods of internal grinding?

1. Center type internal grinding

When grinding, the workpiece rotates around the center line of the main shaft of the headstock. Common internal grinding machines or universal cylindrical grinding machines belong to this form, which is suitable for grinding the inner holes of sleeves, gears, flanges and other parts.

2. Planetary Internal Grinding

During grinding, the workpiece is fixed and does not rotate. In addition to high-speed rotation around its own axis, the grinding wheel also rotates around the center of the hole to be ground at a low speed to achieve circular feed; in addition, the grinding wheel also performs longitudinal feed motion and periodic lateral feed. Give. The lateral feed of the grinding wheel is realized by increasing the radius of gyration of the planetary motion. Planetary internal grinding machines are mainly used for grinding parts that are bulky and inconvenient to rotate.

3. Centerless internal grinding

On the centerless internal grinding machine, the workpiece is supported on the support wheel and the pressure wheel with its finished outer circle, and is driven by the guide wheel to rotate. This grinding method is suitable for grinding the inner hole of thin-walled annular parts.

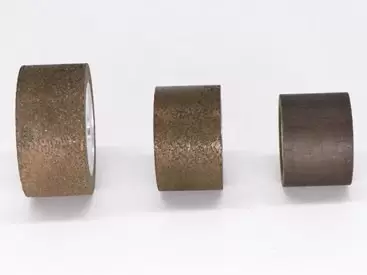

How to choose internal grinding wheel

The selection is based on the workpiece hole, and there should be an appropriate ratio between the two. Usually the diameter of the grinding wheel is 0.5~0.9 of the hole diameter.

| The diameter of the workpiece hole | The diameter of grinding wheel |

| 12-17 | 10 |

| 17-22 | 15 |

| 22-27 | 20 |

| 27-32 | 25 |

| 32-45 | 30 |

| 45-55 | 40 |

| 55-70 | 50 |

| 70-80 | 65 |

| 80-100 | 75 |

-

Internal Grinding Wheel for 420 Stainless Steel

PA Internal Grinding Wheel for 420 Stainless Steel

-

Internal Grinding Wheels for Grinding Bearing Inner Rings

Internal Grinding Wheels for Grinding Bearing Inner Rings

-

Internal Diamond grinding wheel

Resin Bond Internal Diamond grinding wheel

-

cbn internal grinding wheel

CBN Wheel For Internal Grinding