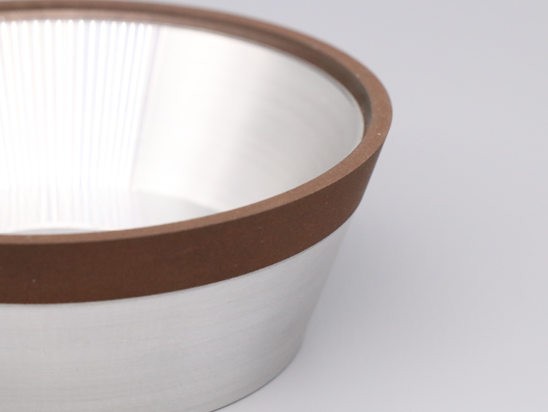

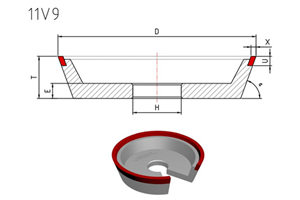

11V9 Diamond Grinding Wheel for Mill Cutter

11V9 diamond and CBN grinding wheel for grinding round tools on CNC machine

Increased rate of material removal with high temperature stability

Increased profile retention of the wheel

Lower grinding force on the work piece

Long wheel life and long dressing interval

Diamond grinding wheel for CNC mill cutters ensure higher material removal without compromising on the surface finish, while ensuring considerable reduction in cycle times. These wheels can be used for both Fresh tool manufacturing and re-sharpening, on CNC Tool and Cutter Grinders.

Application:

For Flut Grinding of Carbide Drills and Endmills

Advantages:

1.Increased rate of material removal with high temperature stability

2.Increased profile retention of the wheel

3.Lower grinding force on the work piece

4.Long wheel life and long dressing interval

5.Low and constant power consumption

| Type | D(mm) | H(mm) | W(mm) | X(mm) |

|

11V9 |

75 | 20, 27 | 3, 5 | 10 |

| 100 | 31.75, 32 | 3, 5 | 10 | |

| 125 | 31.75, 32 | 3, 5 | 10 |

Related Products

-

Gashing Grinding Wheel for Round Tools Grinding

Gashing Grinding Wheel for Round Tools Grinding

-

Flute Grinding Wheel for Carbide Round Tools on CNC Machine

Flute Grinding Wheel for Carbide Round Tools on CNC Machine

-

6A2 Diamond Wheel for PCD Saw Blades

6A2 Diamond Wheel for PCD Saw Blades

-

Diamond and CBN wheels for grinding carbide and HSS. (such as drill, end mill, reamer)

Superabrasive diamond grinding wheels for CNC tool grinder

-

11A2 Vitrified Diamond Grinding Wheel for PCD/PCBN Tools

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.