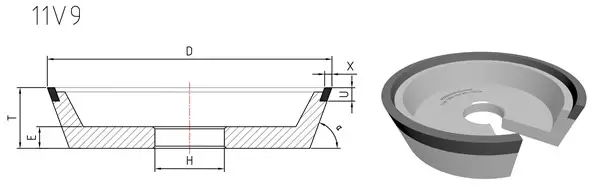

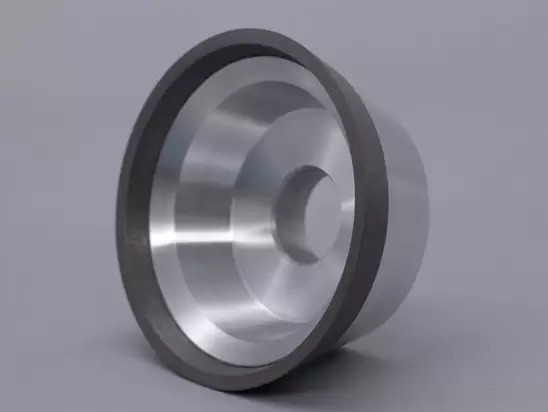

11V9 Hybrid Diamond Grinding Wheel for Rotary Tools

► Hybrid bond : resin (polyimide) and metal bond

► Application: fluting and gashing end mill, drill and reamer

► CNC Tools Grinder: Anca, Walter, Ewag, Schneeberger, etc

Hybrid grinding Wheels ensure higher material removal without compromising on the surface finish, while ensuring considerable reduction in cycle times. These wheels can be used for both Fresh tool manufacturing and re-sharpening, on CNC Tool and Cutter Grinders.

Hybrid bond is used for grinding of solid shank cutting tool process (such as end-mills, drills and reamers)

– Hybrid bond Diamond Wheel : For carbide tool grinding

– Hybrid bond CBN Wheel : For HSS tool grinding

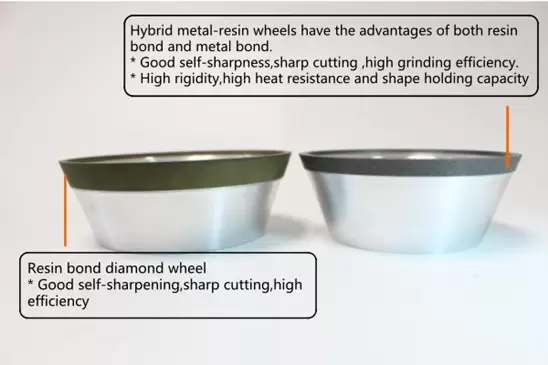

Advantages of hybrid diamond and cbn wheels

Resin (polyimide) bond. Good grinding performance and surface roughness, elasticity, minimal chipping

Metal bond. High wear resistance and high thermal stability, excellent grinding ability and long tool life

Dressing interval: more than double

Tool life: more than 1.5 times

| Type | D(mm) | H(mm) | W(mm) | X(mm) |

|

11V9 |

75 | 20, 27 | 3, 5 | 10 |

| 100 | 31.75, 32 | 3, 5 | 10 | |

| 125 | 31.75, 32 | 3, 5 | 10 |

Case 1 – Fluting for carbide end mill

| Grinding wheel | 3V1 D150 |

| Machine | 5-axis CNC grinder |

| Coolant | Oil |

| Work piece | Carbide end mill |

| Grinding process | Flute |

| Feed rate | 140mm/min |

| Cutting speed | 18m/s |

Case 2 – Gashing for carbide endmill

| Grinding wheel | 12v9 D125 |

| Machine | ANCA 5-axis CNC grinder |

| Coolant | Oil |

| Work piece | Carbide end mill |

| Grinding process | Gash |

| Feed rate | 60 mm/min |

| Cutting speed | 20 m/s |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.