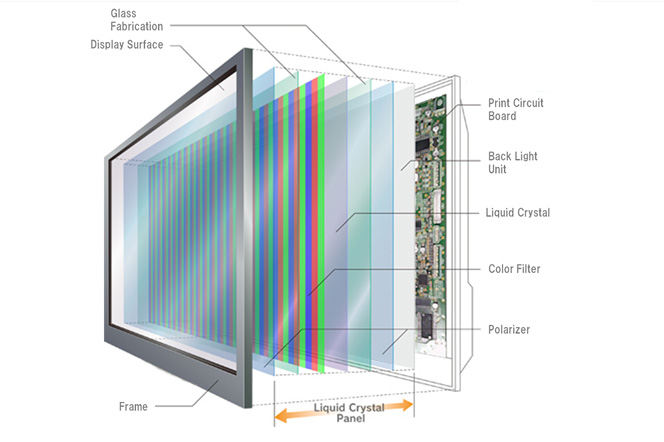

TFT-LCD is a thin film transistor active matrix liquid crystal display, mainly used in smartphones, notebook computers, LCD TVs, etc. During the production process, the four sides of TFT glass substrates (including plain glass substrates, CF glass substrates, TFT array glass substrates, and double-layer glass substrates after being boxed) need to be ground after being cut/split. Edge and edge grinding wheels are applied to TFT-LCD glass substrates, such as linear bilateral edge grinding machines and profiling edge grinding machines to form the required high-gloss arc surfaces on the four edges of the substrate. The quality of the grinding directly causes processing defects. It also greatly affects the processing stability and yield of subsequent processes.

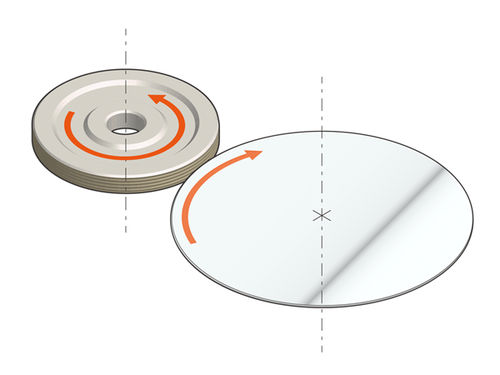

Two forms of edge grinding:

“C” type edge, and “up and down grinding”.

Diamond Wheel for TFT-LCD Edge Grinding

The edge grinding wheel is installed on the grinding head and ishe relative movement of the edge grinding wheel and the glass substrate. For example, the linear double edge machine is realized by the linear motion of the glass substrate and the circular motion of the grinding wheel. The profile edge grinding machine is realized by the glass substrate and the grinding wheel. This is achieved by making a circular motion at the same time. The quality of the grinding wheel, such as the material, shape, mesh number, etc. of the grinding wheel, affects the grinding effect and also determines the length of the grinding distance.

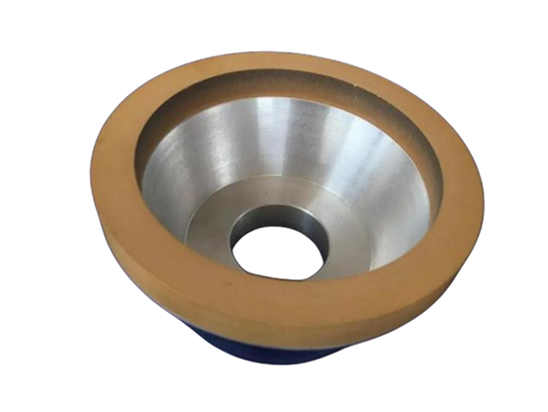

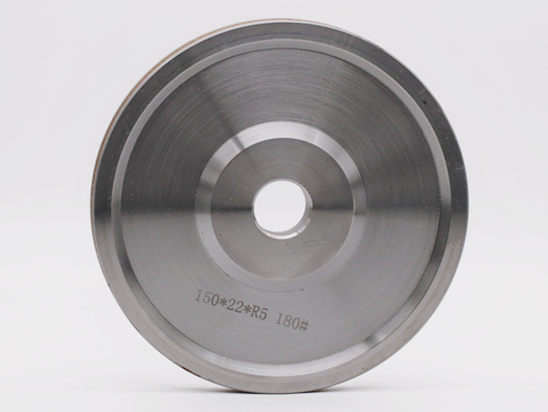

Metal, electroplated and resin diamond grinding wheels are widely used in the TFT-LCD industry, with two shapes: cylindrical and truncated cone. Milling Cylindrical diamond wheel are used for grinding the “C” edge, while milling-shaped resin diamond wheels are used for the upper and lower edges of the glass substrate. Generally, 300 -400 grit for rough grinding, 600-800 grit for fine surface, and 1000 grit for fine polishing.

Diamond grinding wheel designed for fine processing 4 sides of TFT-LCD glass cut, used to processes as C-grinding, R-grinding and corner cut into glass. Diamond grinding wheels are composed of Edge type and ST & Cut type.

Moresuperhard can provide metal bonded, electroplated mounted wheel for glass drilling and edge grinding. Moresuperhard diamond grinding wheel can satisfy the requirements on finish surface and accuracy. Provide the best solution for TFT, Color, filter and Touch Panel grinding.

Metal diamond grinding wheel

Metal bond diamond grinding wheel is suitable for edge grinding on TFT glass and PDP (Plasma Display Panel). Metal bond wheels, featuring long tool life and form withholding ability, make themselves the best candidates for beveling glass substrates of LCD panels.

Features of Metal Bond Wheel

* Improve the chipping after grinding

* Long life time, reduce the frequency of wheel changing

* Enhance productivity and yield rate

Resin diamond grinding wheel

Resin bond diamond grinding wheel is suitable for chamfering electrode section of LCD panels and finish edge grinding. Resin bond wheels provide alternatives for customers pursuing better surface roughness.

Electrplated diamond edge grinding wheel

Diamond grinding wheel designed for fine processing 4 sides of TFT-LCD glass cut, used to processes as C-grinding, R-grinding and corner cut into glass. Diamond grinding wheels are composed of Edge type and ST & Cut type.

Electroplated diamond edge wheel is used to grind edge of flat display to improve bending strength of workpiece by removing vertical crack in scribing process.

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.