Diamond Dicing Blades For Wafer Scribing

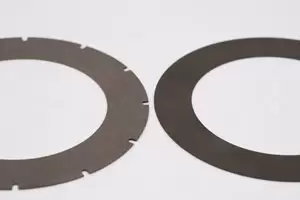

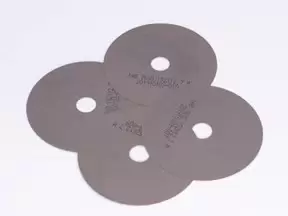

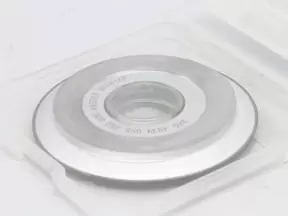

1A8 Ultra-thin diamond dicing blade

Blade thickness: 0.03 mm – 0.3 mm

Silicon wafers of thickness: 0.5 mm, 1 mm, 2 mm, 3 mm and 5 mm

Inducing as low as possible frontside and backside chipping of silicon wafer

Applications: Scribing silicon wafers, compound semiconductor wafers (GaAs, Gap), oxide wafers (LiTaO3), glass, crystal, quart, LiTaO3, ceramics, optical, QFN, splitter,BGA, CSP,magnetic materials, PCB, silicon, etc

Diamond dicing blade is used for grooving , cutting silicon wafer, compound semiconductors, glass and other materials in electronic information industry. Diamond dicing blade is one of new products developed . Our dicing blades include diamond hub dicing blade and diamond hubless dicing blade. The binders include resin bond dicing blade, metal bond dicing blade and electroformed nickel dicing blade.

How to selection of the correct types of wafer dicing blades to cut materials

* Binder of resin bond (soft strength) dicing blade, scribing hard and brittle material

* Binder of metal bond (medium strength) dicing blade

* Binder of electroplated bond (hard bond), scribing softer material

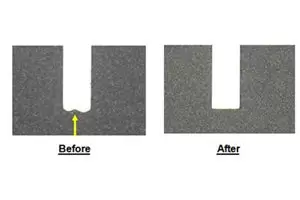

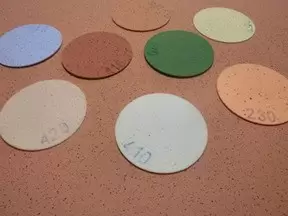

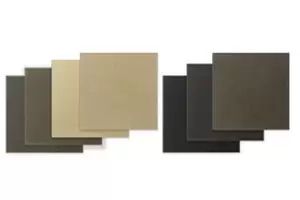

Dresser Board for dressing dicing blades

Dresser board is used for dressing and edged blade row, to increase sharpness, and reduce the chipping of the work piece, to reshape and perfect the blade edge to a flat edge

Applications of wafer diamond dicing blade

Scribing / cutting silicon wafers, compound semiconductor wafers (GaAs, Gap), oxide wafers (LiTaO3), glass, crystal, quart, LiTaO3, ceramics, optical, QFN, splitter, electronic parts, optical devices, semiconductor packages, BGA, CSP, various types of semiconductor packages, ceramics, magnetic materials, PCB, silicon

| Types | Features | Product Name | |

|

Electroformed dicing blade |

• Good chip removal and cooling performance • Can carry on the difficult angle cutting and the step cutting processing• By adjusting the blades strength, can reduce the snake like cutting and blade damage • The workpiece has no flying edge, burr residue and high yield |

Hub dicing blade |

|

| Application: Scribing dicing IC wafers, gallium arsenide, gallium phosphide, epoxy resin board, alloy frame, ceramic substrate, composite board with interlayer, etc | |||

Resin bond dicing blade |

• High processing quality for cutting of hard, brittle materials

• Improved cut quality on hard materials • Excellent cutting ability that help reduce chippingm fractures

|

Hubless dicing blade |

|

| Application: cutting scribing glass (optical devices, fiber optics), quartz (optical splitters, saw devices), LiTa03 LiNb03 (devices), BGA, QFN (copper epoxy molding ), splitter, sapphire, ceramic substrate, alumina, aliminum nitride, etc | |||

Metal bond dicing balde

|

• High rigidity minimized wavy & slant cutting

• Excellent rigidity and cut quality |

||

| Application: Scribing electronic parts, optical devices, semiconductor packages, BGA, CSP, PCB, ceramic, glass, quartz, crystal, ferrite, optical communication (Faraday), etc | |||

|

Electroformed dicing balde |

• Wide selection of blade options

• Proprietary thin-blade technology • Blade thickness – 0.03 mm to 0.3 mm • Available for both dicing saws and slicers |

||

| Application: Scribing dicing silicon wafers, copper wafer and compound semiconductor wafers ( such as GaAs and SiC) , resistance, ceramic, packaging materials, lithium niobate, lithium tantalate, etc | |||

| Other specification can be produced according to customers’ requirements | |||

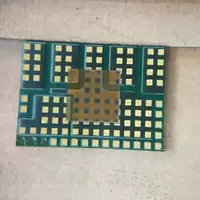

The Case of Metal Diamond Dicing Blades for PCB

| Workpiece | PCB Material

1.2mm thick resin containing copper layer |

| Dicing Requirements | Cutting without burrs |

| Incision perpendicularity < 0.005mm | |

| Cutting dimensional error < 0.02mm | |

| Snake cutting is not allowed | |

| Dicing / Scribing Machine | Disco DAD3350 scribing machine |

| Diamond Dicing Blade

|

Metal Diamond Dicing Blade |

| 58D x 0.15T x 40H (Grit 400# ) | |

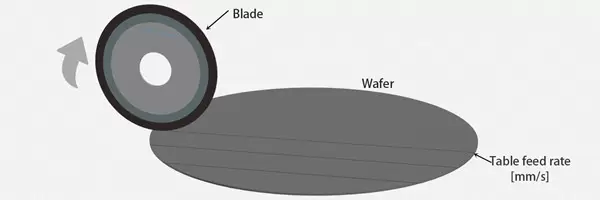

| Cutting Parameters | 1. Cutting direction: Straight cutting

2. Spindle speed: 30000rpm

3. Feed speed: 50mm/S 4. Cooling water: pure water

|

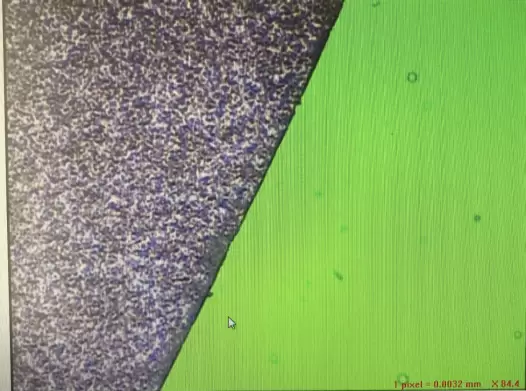

Case of metal diamond dicing blade:

Our customer using other brand diamond dicing blade have chipping before, but try Moresuperhard metal diamond dicing blade do not occur chipping.

| Blade size | Ø52mm*Ø40mm*0.11mm |

| Workpiece size | 2mm |

| RPM Speed | 20,000 RPM |

| Feed Speed | 700µm/s ( can adjust. Opening to cut is 0.12mm, and the depth of the cut is 0.18mm) |

| Depth of cut | 200µm |

| Length of cut: | 130mm |

| Cutting model | Cutting model |

| Cut depth | Cut depth |

| Coolant | Water |

| Cutting Material

|

– Cubic Zirconia(8.5 hardness)

– Sapphire (9-Mohs hardness scale) – Natural stone: Mohs hardness 7-8 |

Related Products

-

Edge Grinding Wheel, Silicon Wafer Chamfering

Edge Grinding Wheel, Silicon Wafer Chamfering

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Si/SiO2 Wafer

Si/SiO2 Wafer

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Metal bond Diamond Dicing Blades

Metal bond Diamond Dicing Blades

-

Electroformed Diamond Dicing Blade - Hub Type

Electroformed Diamond Dicing Blade – Hub Type

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer Scribing

-

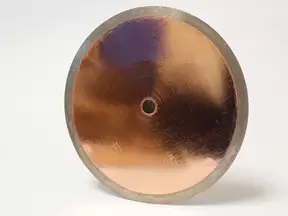

Metal bond diamond cutting wheel , steel core with copper plated is used for grooving and cutting carbide,optics glass, sapphire, ceramics , magnetic materials and semiconductor material

Metal Diamond Wafer Blade with Copper Plated

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.