Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

Honing Thermal Spraying Coatings in Cylinder Bores

Improved shape after honing

Higher precision

Description of diamond honing tools for thermal spraying coated

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.

We optimise the honing tools by mounting hones for processing a wide range of materials, such as aluminium, thermal spray coatings (e.g. APS-, LDS-, CBC-, RSW- or FeC coatings / PTWA), free cutting steel , tool steel, hardened steel (e.g. 100Cr6, 16MnCr5, C45, VA-steel, ST52, 17CrNiMo6, 34CrNiMo6, 42CrMo4V, 9SMn28k), various types of grey cast iron (e.g., G26Cr, GGG40 and others) as well as custom materials, such as CFC, graphite, AluSil (AlSi17), DISPAL, titanium-aluminium alloys and galvanized NiKaSil- or hardchromium-coatings.

Application of diamond honing tools

Used for Thermal spray coatings in cylinder bores of internal combustion engines. Energy efficient engines with low friction, reduced length and lower weight as well as lower production costs can be achieved due to the new process chain for the manufacture of cylinder bores.

| Model | size | grit | ||

|

Diamond Honing Stone |

L*W*H(mm) | 30#~150#

150#~320# 400#~1000# |

||

| 50 | 7.62 | 18 | ||

| 100 | 8 | 8 | ||

Other specifications honing stone can be made according to customers’ requirement.

Related Products

-

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

-

Single Pass Diamond Honing Tools, Electroplated Diamond Reamers

Single Pass Diamond Honing Tools, Electroplated Diamond Reamers

-

Single Stroke Diamond Honing Reamer

Single Stroke Diamond Honing Reamer

-

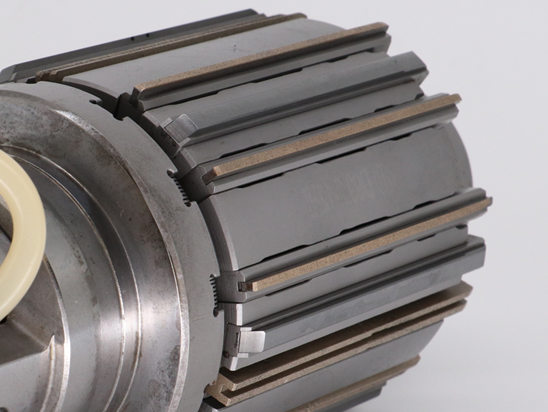

Cylinder honing head, diamond honing heads

Cylinder honing head, diamond honing heads

-

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

-

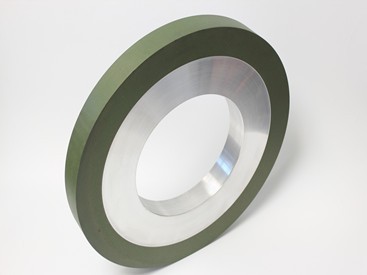

vitrified diamond grinding wheel used in thermal spraying coating

Vitrified Diamond Grinding Wheel for Hard Surface in Thermal Spraying Coating

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.